Bem-vindo!

Confirme suas preferências

Atualizar preferências

Sugestões de produtos

Product Family suggestions

Kennametal ao seu serviço

Olá., User Name

Sua conta selecionada:

Existe um problema com a sua conta. Entre em contato com o suporte ao cliente.

Conta do vendedor Alterar conta

Conta de entrega Alterar conta

- Painel de controle

- Gerenciar pedidos

- Gerenciar canais

- Catálogo de endereços

Notificações

Marcar todas como lidas- Alterar senha

- Meu perfil

- Desconectar

Itens adicionado com sucesso ao carrinho

Ver o carrinho

Ver o carrinho

Fresar mais por menos com nossas ofertas por tempo limitado! Compre agora

Kennametal ao seu serviço

Itens adicionado com sucesso ao carrinho

Ver o carrinho

Ver o carrinho

Editando solução

Adicionando solução

Nome da solução:{{SolutionName}}- Produtos

- /

- 7792VXD12 Modular Head Screw-On • Inch

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

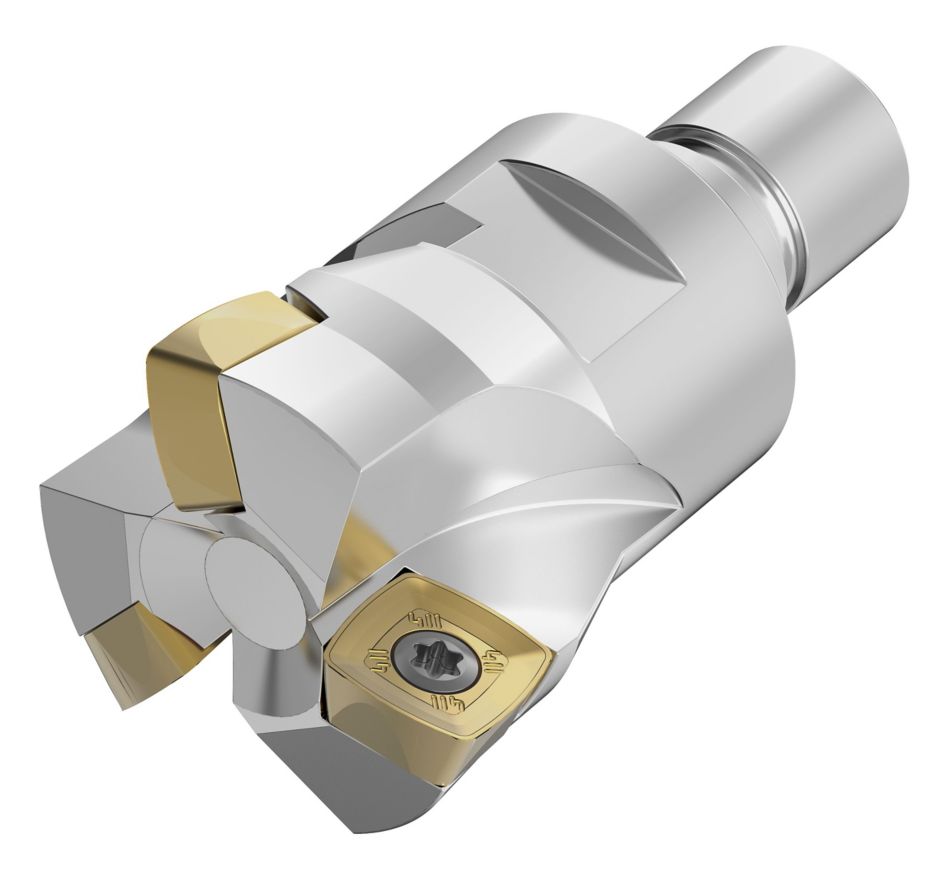

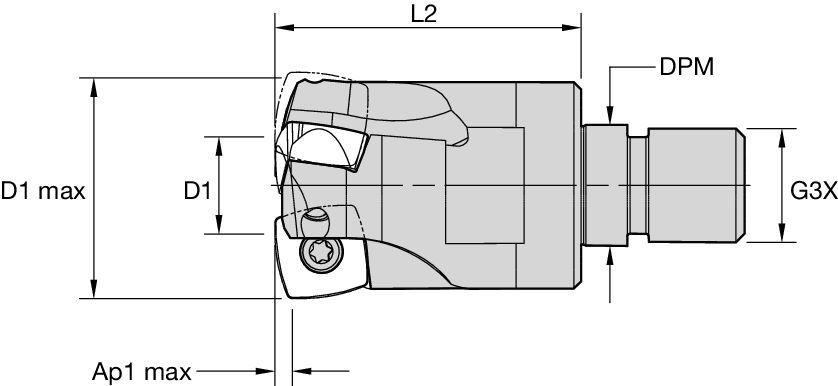

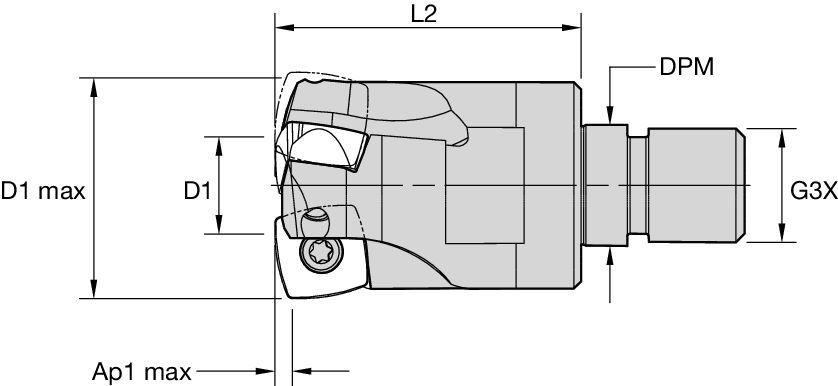

7792VXD12 Modular Head Screw-On • Inch

High-Feed Milling Cutters

Características e benefícios

- Ultra-fine pitch cutters available to increase material removal rates, especially on high-temp alloys.

- Positive design to support lower cutting forces and long overhang usage.

- Ramping and plunge milling capabilities.

- Screw-on cutters provide better rigidity and stability when used with small spindles: BT30, BT40, DV40, HSK50, HSK63, etc.

- Screw-on cutters can be less expensive when compared to cylindrical shank cutters due to their higher flexibility through multiple holder combinations.

Usos e aplicações

Spiral Circular

Slotting: Shoulder

Fresamento de face

Fresamento helicoidal

Fresamento de rampa: blank

Haste — Screw-On

Fresamento — Refrigeração interna

Fresamento de cavidade

Rebaixamento

Fresamento de mergulho: ponta esférica

Inclined Square End Mill

Guia de seleção de insertos • IC 12

| 7792 Series • IC12 • Insert Selection Guide | ||||||

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1-P2 | ...M41 | KCPM40 | …M41 | KCPM40 | …GP | KCPM40 |

| P3-P4 | ...M41 | KCPM40 | …D411 | SP6519 | …D41 | KCPM40 |

| P5-P6 | ...M41 | KCPM40 | ...D41 | SP6519 | ...D41 | X500 |

| M1-M2 | ...M41 | KCSM40 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| M3 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| K1-K2 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| K3 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S3 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S4 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| H1 | …M | KCKP10 | …M | KCKP10 | …D | KCPM40 |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..D721 | .011 | .041 | .066 | .008 | .029 | .047 | .006 | .022 | .035 | .005 | .019 | .030 | .005 | .017 | .028 | .E..D721 |

| .E..D41 | .014 | .046 | .072 | .010 | .033 | .051 | .008 | .024 | .038 | .007 | .021 | .033 | .006 | .019 | .030 | .E..D41 |

| .E..D411 | .014 | .046 | .072 | .010 | .033 | .051 | .008 | .024 | .038 | .007 | .021 | .033 | .006 | .019 | .030 | .E..D411 |

| .S..GP | .020 | .051 | .077 | .015 | .036 | .055 | .011 | .027 | .041 | .009 | .024 | .035 | .009 | .022 | .032 | .S..GP |

| .S..D | .020 | .051 | .077 | .015 | .036 | .055 | .011 | .027 | .041 | .009 | .024 | .036 | .009 | .022 | .032 | .S..D |

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..D721 | .013 | .048 | .078 | .010 | .035 | .056 | .007 | .026 | .041 | .006 | .022 | .036 | .006 | .021 | .033 | .E..D721 |

| .E..D41 | .017 | .054 | .086 | .012 | .039 | .061 | .009 | .029 | .045 | .008 | .025 | .039 | .007 | .023 | .036 | .E..D41 |

| .E..D411 | .017 | .054 | .086 | .012 | .039 | .061 | .009 | .029 | .045 | .008 | .025 | .039 | .007 | .023 | .036 | .E..D411 |

| .S..GP | .024 | .061 | .092 | .017 | .043 | .065 | .013 | .032 | .048 | .011 | .028 | .042 | .010 | .026 | .038 | .S..GP |

| .S..D | .024 | .061 | .092 | .017 | .043 | .065 | .013 | .032 | .048 | .011 | .028 | .042 | .010 | .026 | .038 | .S..D |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..D721 | .015 | .054 | .088 | .011 | .039 | .063 | .008 | .029 | .046 | .007 | .025 | .040 | .007 | .023 | .037 | .E..D721 |

| .E..D41 | .019 | .061 | .097 | .014 | .044 | .069 | .010 | .033 | .051 | .009 | .028 | .044 | .008 | .026 | .040 | .E..D41 |

| .E..D411 | .019 | .061 | .097 | .014 | .044 | .069 | .010 | .033 | .051 | .009 | .028 | .044 | .008 | .026 | .040 | .E..D411 |

| .S..GP | .027 | .068 | .104 | .019 | .049 | .073 | .014 | .036 | .054 | .013 | .031 | .047 | .012 | .029 | .043 | .S..GP |

| .S..D | .027 | .068 | .104 | .019 | .049 | .074 | .014 | .036 | .054 | .013 | .031 | .047 | .012 | .029 | .043 | .S..D |

| Insert Geometry |  | Programmed Feed per Tooth (fz) | Insert Geometry | ||

| Max .354" insert engagement (ae radial engagement) | |||||

| .E..D721 | .002 | .008 | .013 | .E..D721 | |

| .E..D41 | .003 | .009 | .014 | .E..D41 | |

| .E..D411 | .003 | .009 | .014 | .E..D411 | |

| .S..GP | .004 | .010 | .015 | .S..GP | |

| .S..D | .004 | .010 | .015 | .S..D | |

| Light | General | Heavy |

Velocidades iniciais recomendadas [m/min.]

| Material Group | GH2 | KC510M | KC522M | KC725M | KCK15 | KCPK30 | KCPM20 | KCPM40 | KCSM40 | SC3025 | SC6525 | SP6519 | X400 | X500 | |||||||||||||||||||||||||||||

| P | 1 | – | – | – | – | – | – | 395 | 340 | 325 | 410 | 320 | 280 | – | – | – | 545 | 475 | 445 | 660 | 580 | 540 | 355 | 310 | 295 | – | – | – | – | – | – | 445 | 305 | 170 | 355 | 260 | 155 | 310 | 230 | 145 | 325 | 240 | 155 |

| 2 | – | – | – | – | – | – | 330 | 290 | 240 | 320 | 245 | 210 | – | – | – | 335 | 305 | 275 | 410 | 370 | 330 | 300 | 260 | 215 | – | – | – | – | – | – | 390 | 270 | 145 | 310 | 230 | 140 | 275 | 205 | 125 | 290 | 215 | 140 | |

| 3 | – | – | – | – | – | – | 305 | 260 | 210 | 280 | 210 | 180 | – | – | – | 305 | 275 | 245 | 370 | 330 | 305 | 275 | 235 | 190 | – | – | – | – | – | – | 350 | 240 | 125 | 275 | 200 | 120 | 240 | 180 | 115 | 250 | 185 | 120 | |

| 4 | – | – | – | 295 | 240 | 205 | 270 | 220 | 180 | 235 | 175 | 145 | – | – | – | 230 | 210 | 190 | 275 | 260 | 230 | 245 | 205 | 160 | – | – | – | – | – | – | 250 | 175 | 95 | 210 | 150 | 90 | 180 | 130 | 85 | 190 | 145 | 90 | |

| 5 | – | – | – | – | – | – | 220 | 205 | 180 | 310 | 235 | 190 | – | – | – | 310 | 275 | 250 | 330 | 300 | 275 | 205 | 185 | 160 | 165 | 120 | 85 | – | – | – | 190 | 145 | 95 | 170 | 125 | 85 | – | – | – | 155 | 120 | 85 | |

| 6 | – | – | – | – | – | – | 200 | 150 | 120 | 210 | 155 | 125 | – | – | – | 190 | 160 | 0 | 230 | 205 | 175 | 180 | 140 | 110 | 140 | 100 | 60 | – | – | – | 170 | 120 | 70 | 145 | 100 | 60 | – | – | – | 130 | 95 | 60 | |

| M | 1 | – | – | – | – | – | – | 245 | 215 | 200 | – | – | – | – | – | – | 245 | 220 | 185 | 270 | 240 | 210 | 235 | 205 | 185 | 315 | 225 | 140 | – | – | – | 230 | 185 | 145 | 325 | 235 | 140 | – | – | – | 300 | 220 | 140 |

| 2 | – | – | – | – | – | – | 220 | 190 | 155 | – | – | – | – | – | – | 220 | 190 | 170 | 245 | 210 | 190 | 210 | 180 | 150 | 280 | 205 | 130 | – | – | – | 310 | 220 | 130 | 280 | 205 | 125 | – | – | – | 265 | 190 | 120 | |

| 3 | – | – | – | – | – | – | 170 | 145 | 115 | – | – | – | – | – | – | 175 | 155 | 140 | 190 | 175 | 150 | 155 | 140 | 110 | 230 | 165 | 105 | – | – | – | 250 | 180 | 110 | 235 | 170 | 100 | – | – | – | 215 | 155 | 95 | |

| K | 1 | 300 | 220 | 145 | 355 | 320 | 290 | 275 | 245 | 220 | – | – | – | 505 | 460 | 410 | 355 | 320 | 290 | 430 | 390 | 355 | – | – | – | – | – | – | 475 | 330 | 180 | 470 | 325 | 175 | 355 | 265 | 170 | – | – | – | 335 | 240 | 145 |

| 2 | 260 | 190 | 125 | 275 | 245 | 230 | 215 | 190 | 180 | – | – | – | 400 | 355 | 330 | 280 | 250 | 230 | 340 | 305 | 280 | – | – | – | – | – | – | 400 | 275 | 145 | 365 | 250 | 140 | 290 | 210 | 130 | – | – | – | 245 | 185 | 125 | |

| 3 | 220 | 175 | 120 | 235 | 210 | 190 | 180 | 160 | 145 | – | – | – | 335 | 300 | 275 | 235 | 210 | 190 | 290 | 260 | 240 | – | – | – | – | – | – | 330 | 230 | 125 | – | – | – | 265 | 190 | 120 | – | – | – | 205 | 160 | 115 | |

| N | 1 | 3295 | 1890 | 480 | 770 | 685 | 630 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 3295 | 1890 | 480 | 695 | 640 | 590 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 2560 | 1460 | 355 | 695 | 640 | 590 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 40 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 35 | 75 | 55 | 35 | – | – | – | – | – | – | 65 | 50 | 30 | – | – | – | 60 | 40 | 30 |

| 2 | – | – | – | – | – | – | 50 | 40 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 35 | 70 | 50 | 35 | – | – | – | – | – | – | 60 | 40 | 25 | – | – | – | 55 | 40 | 25 | |

| 3 | – | – | – | – | – | – | 60 | 50 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 50 | 35 | 80 | 55 | 35 | – | – | – | – | – | – | 65 | 50 | 30 | – | – | – | 60 | 50 | 30 | |

| 4 | – | – | – | – | – | – | 85 | 60 | 40 | – | – | – | – | – | – | 80 | 60 | 40 | – | – | – | 80 | 60 | 40 | 110 | 80 | 50 | – | – | – | – | – | – | 95 | 70 | 45 | – | – | – | 90 | 65 | 40 | |

| H | 1 | – | – | – | 190 | 155 | 110 | 145 | 110 | 85 | – | – | – | – | – | – | – | – | – | 170 | 140 | 115 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 115 | 85 | 55 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 95 | 70 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Material Group | GH2 | KC510M | KC522M | KC725M | KCK15 | KCPK30 | KCPM20 | KCPM40 | KCSM40 | SC3025 | SC6525 | SP6519 | X400 | X500 | |||||||||||||||||||||||||||||

| P | 1 | – | – | – | – | – | – | 1295 | 1120 | 1060 | 1025 | 905 | 845 | – | – | – | 1790 | 1555 | 1460 | 2165 | 1910 | 1770 | 1165 | 1025 | 965 | – | – | – | – | – | – | 1460 | 1000 | 550 | 1165 | 845 | 510 | 1025 | 750 | 475 | 1060 | 785 | 510 |

| 2 | – | – | – | – | – | – | 1080 | 940 | 785 | 865 | 750 | 630 | – | – | – | 1105 | 1000 | 905 | 1340 | 1220 | 1080 | 985 | 845 | 710 | – | – | – | – | – | – | 1280 | 890 | 475 | 1025 | 750 | 450 | 905 | 670 | 415 | 940 | 710 | 450 | |

| 3 | – | – | – | – | – | – | 1000 | 845 | 690 | 785 | 670 | 550 | – | – | – | 1000 | 905 | 805 | 1220 | 1080 | 1000 | 905 | 770 | 630 | – | – | – | – | – | – | 1140 | 785 | 415 | 905 | 650 | 395 | 785 | 590 | 370 | 830 | 610 | 395 | |

| 4 | – | – | – | 965 | 785 | 670 | 890 | 725 | 590 | 710 | 590 | 475 | – | – | – | 750 | 690 | 630 | 905 | 845 | 750 | 805 | 670 | 535 | – | – | – | – | – | – | 830 | 570 | 310 | 690 | 490 | 295 | 590 | 430 | 275 | 630 | 475 | 295 | |

| 5 | – | – | – | – | – | – | 725 | 670 | 590 | 590 | 535 | 475 | – | – | – | 1025 | 905 | 830 | 1080 | 985 | 905 | 670 | 610 | 535 | 530 | 390 | 280 | – | – | – | 630 | 475 | 310 | 550 | 415 | 275 | – | – | – | 510 | 395 | 275 | |

| 6 | – | – | – | – | – | – | 650 | 490 | 395 | 510 | 395 | 310 | – | – | – | 630 | 535 | – | 750 | 670 | 570 | 590 | 450 | 355 | 450 | 730 | 200 | – | – | – | 550 | 395 | 235 | 475 | 335 | 200 | – | – | – | 430 | 310 | 200 | |

| M | 1 | – | – | – | – | – | – | 805 | 710 | 650 | 670 | 590 | 535 | – | – | – | 805 | 725 | 610 | 890 | 785 | 690 | 770 | 670 | 610 | 1020 | 730 | 450 | – | – | – | 750 | 610 | 475 | 1060 | 770 | 450 | – | – | – | 985 | 725 | 450 |

| 2 | – | – | – | – | – | – | 725 | 630 | 510 | 610 | 510 | 430 | – | – | – | 725 | 630 | 550 | 805 | 690 | 630 | 690 | 590 | 490 | 910 | 675 | 415 | – | – | – | 1025 | 725 | 430 | 925 | 670 | 415 | – | – | – | 865 | 630 | 395 | |

| 3 | – | – | – | – | – | – | 550 | 475 | 370 | 450 | 395 | 310 | – | – | – | 570 | 510 | 450 | 630 | 570 | 490 | 510 | 450 | 355 | 750 | 530 | 340 | – | – | – | 830 | 590 | 355 | 770 | 550 | 335 | – | – | – | 710 | 510 | 310 | |

| K | 1 | 985 | 725 | 475 | 1165 | 1045 | 940 | 905 | 805 | 725 | – | – | – | 1655 | 1520 | 1340 | – | – | – | 1415 | 1280 | 1165 | – | – | – | – | – | – | 1555 | 1080 | 590 | 1535 | 1060 | 570 | 1165 | 865 | 550 | – | – | – | 1105 | 785 | 475 |

| 2 | 845 | 630 | 415 | 905 | 805 | 750 | 710 | 630 | 590 | – | – | – | 1320 | 1165 | 1080 | – | – | – | 1120 | 1000 | 925 | – | – | – | – | – | – | 1320 | 905 | 475 | 1200 | 830 | 450 | 940 | 690 | 430 | – | – | – | 805 | 610 | 415 | |

| 3 | 725 | 570 | 395 | 770 | 690 | 630 | 590 | 535 | 475 | – | – | – | 1105 | 985 | 905 | – | – | – | 940 | 845 | 785 | – | – | – | – | – | – | 1080 | 750 | 415 | – | – | – | 865 | 630 | 395 | – | – | – | 670 | 535 | 370 | |

| N | 1 | 10805 | 6200 | 1570 | 2520 | 2245 | 2065 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 10805 | 6200 | 1570 | 2280 | 2105 | 1925 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 8405 | 4780 | 1165 | 2280 | 2105 | 1925 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 155 | 140 | 95 | 140 | 120 | 95 | – | – | – | 140 | 120 | 95 | – | – | – | 155 | 140 | 120 | 240 | 175 | 110 | – | – | – | – | – | – | 215 | 155 | 90 | – | – | – | 185 | 140 | 90 |

| 2 | – | – | – | – | – | – | 155 | 140 | 95 | 140 | 120 | 95 | – | – | – | 140 | 120 | 95 | – | – | – | 155 | 140 | 120 | 220 | 160 | 100 | – | – | – | – | – | – | 185 | 140 | 85 | – | – | – | 175 | 140 | 85 | |

| 3 | – | – | – | – | – | – | 200 | 155 | 95 | 180 | 140 | 95 | – | – | – | 180 | 140 | 95 | – | – | – | 200 | 155 | 120 | 255 | 180 | 115 | – | – | – | – | – | – | 215 | 155 | 95 | – | – | – | 200 | 155 | 95 | |

| 4 | – | – | – | – | – | – | 275 | 200 | 140 | 235 | 180 | 120 | – | – | – | 235 | 180 | 120 | – | – | – | 260 | 200 | 140 | 355 | 260 | 165 | – | – | – | – | – | – | 310 | 235 | 145 | – | – | – | 290 | 215 | 140 | |

| H | 1 | – | – | – | 630 | 510 | 355 | 475 | 355 | 275 | – | – | – | – | – | – | – | – | – | 550 | 450 | 370 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 370 | 275 | 180 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 310 | 235 | 140 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |