Bem-vindo!

Confirme suas preferências

Atualizar preferências

Sugestões de produtos

Product Family suggestions

Kennametal ao seu serviço

Olá.,

User Name

Sua conta selecionada:

Existe um problema com a sua conta. Entre em contato com o suporte ao cliente.

Conta do vendedor

Alterar conta

Conta de entrega

Alterar conta

- Painel de controle

- Gerenciar pedidos

- Gerenciar canais

- Catálogo de endereços

-

Notificações

Marcar todas como lidas - Alterar senha

- Meu perfil

- Desconectar

Itens

adicionado com sucesso ao carrinho

Ver o carrinho

Ver o carrinho

Fresar mais por menos com nossas ofertas por tempo limitado!

Compre agora

Kennametal ao seu serviço

Itens

adicionado com sucesso ao carrinho

Ver o carrinho

Ver o carrinho

Editando solução

Adicionando solução

Nome da solução: {{SolutionName}}- Produtos

- /

- Mill 4™-12KT • Inserto de metal duro • LNGQ-HD • Usinagem pesada

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

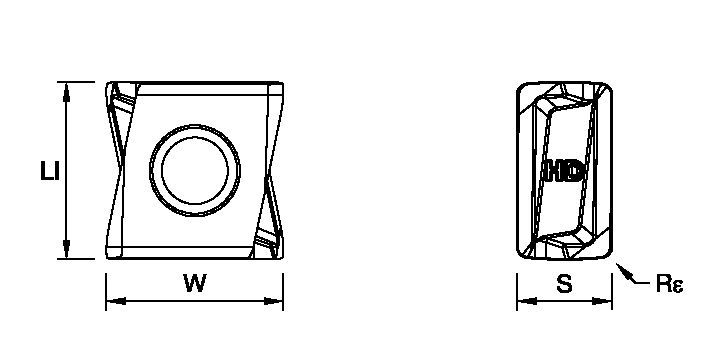

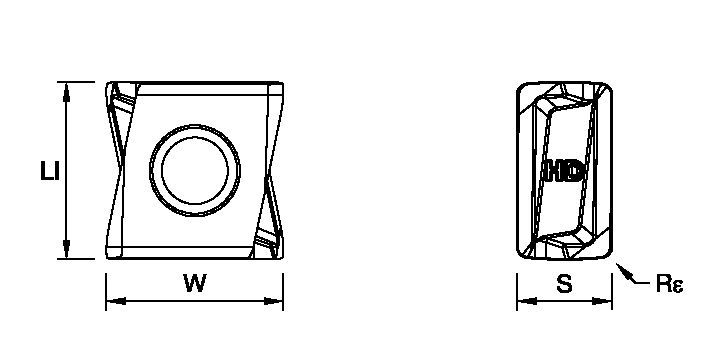

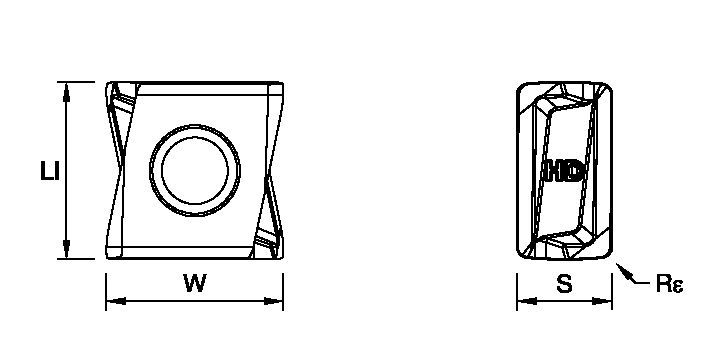

Mill 4™-12KT • Inserto de metal duro • LNGQ-HD • Usinagem pesada

Inserto de fresamento de canto com quatro arestas de corte por inserto, retificado com precisão

Características e benefícios

- Inserto retificado de precisão para melhor acabamento superficial.

- A interface pastilha/encaixe garante estabilidade e desempenho consistente em aplicações difíceis.

- Até 15% menos consumo de energia.

- Fácil indexação do inserto através da fixação do parafuso.

Guia de seleção de insertos

| Mill 4-12KT™ • Insert Selection Guide | ||||||

| Material Group | Light

|

General

|

Heavy

|

|||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear

|

| toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1-P2 | .E..GE | KC522M | .E..PU | KCPM40 | .E..HD | KCPM40 |

| P3-P4 | .E..GE | KC522M | .E..PU | KCPM40 | .E..HD | KCPM40 |

| P5-P6 | .E..GE | KC522M | .E..PU | KC725M | .E..HD | KCPK30 |

| M1-M2 | .E..GE | KC522M | .E..PU | KCSM40 | .E..HD | KCPM40 |

| M3 | .E..GE | KC522M | .E..GE | KCSM40 | .E..HD | KCPM40 |

| K1-K2 | .E..GE | KCK15 | .E..PU | KCK20B | .E..HD | KCK15 |

| K3 | .E..GE | KCK20B | .E..PU | KCK20B | .E..HD | KCK20B |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | .E..GE | KC522M | .E..PU | KCSM40 | – | – |

| S3 | .E..GE | KC522M | .E..GE | KCSM40 | – | – |

| S4 | .E..GE | KC522M | .E..GE | KCSM40 | – | – |

| H1 | – | – | – | – | – | – |

Avanços iniciais recomendados [mm]

| Mill 4-12KT™ • Recommended Starting Feeds [mm/th] | |||||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .E..GE | 0,12 | 0,33 | 0,09 | 0,25 | 0,08 | 0,22 | 0,07 | 0,2 | 0,07 | 0,2 | |||||

| .E..PU | 0,12 | 0,35 | 0,45 | 0,09 | 0,3 | 0,4 | 0,08 | 0,25 | 0,35 | 0,07 | 0,2 | 0,33 | 0,07 | 0,2 | 0,3 |

| .E..HD | 0,12 | 0,35 | 0,55 | 0,09 | 0,3 | 0,44 | 0,08 | 0,25 | 0,38 | 0,07 | 0,2 | 0,36 | 0,07 | 0,2 | 0,35 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

Avanços recomendados iniciais [IPT]

| Mill 4-12KT™ • Recommended Starting Feeds [IPT] | |||||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .E..GE | 0.005 | 0.013 | 0.004 | 0.01 | 0.003 | 0.009 | 0.003 | 0.008 | 0.003 | 0.008 | |||||

| .E..PU | 0.005 | 0.014 | 0.018 | 0.004 | 0.012 | 0.016 | 0.003 | 0.01 | 0.014 | 0.003 | 0.008 | 0.013 | 0.003 | 0.008 | 0.012 |

| .E..HD | 0.005 | 0.014 | 0.022 | 0.004 | 0.012 | 0.017 | 0.003 | 0.01 | 0.015 | 0.003 | 0.008 | 0.014 | 0.003 | 0.008 | 0.014 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

Velocidades iniciais recomendadas [m/min.]

| Mill 4™-12KT • Recommended Starting Speeds [m/min] | ||||||||||||||||||||||

| Grade | KC522M | KCK15 | KCK20B | KCPK30 | KCPM40 | KCSM40 | KC725M | |||||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 1085 | 935 | 885 | – | – | – | – | – | – | 1495 | 1295 | 1215 | 970 | 855 | 805 | 1150 | 1050 | 985 | 855 | 755 | 705 |

| 2 | 900 | 785 | 655 | – | – | – | – | – | – | 920 | 835 | 755 | 820 | 705 | 590 | 985 | 885 | 720 | 720 | 625 | 525 | |

| 3 | 835 | 705 | 575 | – | – | – | – | – | – | 835 | 755 | 675 | 755 | 640 | 525 | 920 | 785 | 640 | 655 | 560 | 460 | |

| 4 | 740 | 605 | 490 | – | – | – | – | – | – | 625 | 575 | 525 | 675 | 560 | 445 | 785 | 675 | 540 | 590 | 490 | 395 | |

| 5 | 605 | 560 | 490 | – | – | – | – | – | – | 855 | 755 | 690 | 560 | 510 | 445 | 655 | 590 | 525 | 490 | 445 | 395 | |

| 6 | 540 | 410 | 330 | – | – | – | – | – | – | 525 | 445 | 360 | 490 | 375 | 295 | 590 | 460 | 330 | 425 | 330 | 260 | |

| M | 1 | 675 | 590 | 540 | – | – | – | – | – | – | 675 | 605 | 510 | 640 | 560 | 510 | 855 | 625 | 375 | 560 | 490 | 445 |

| 2 | 605 | 525 | 425 | – | – | – | – | – | – | 605 | 525 | 460 | 575 | 490 | 410 | 755 | 560 | 345 | 510 | 425 | 360 | |

| 3 | 460 | 395 | 310 | – | – | – | – | – | – | 475 | 425 | 375 | 425 | 375 | 295 | 625 | 460 | 280 | 375 | 330 | 260 | |

| K | 1 | 755 | 675 | 605 | 1380 | 1250 | 1115 | 1180 | 950 | 8 | 970 | 870 | 785 | – | – | – | – | – | – | – | – | – |

| 2 | 590 | 525 | 490 | 1100 | 970 | 900 | 920 | 755 | 640 | 770 | 690 | 625 | – | – | – | – | – | – | – | – | – | |

| 3 | 490 | 445 | 395 | 920 | 820 | 755 | 690 | 575 | 525 | 640 | 575 | 525 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 130 | 115 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 195 | 150 | 80 | 115 | 100 | 80 |

| 2 | 130 | 115 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 180 | 130 | 80 | 115 | 100 | 80 | |

| 3 | 165 | 130 | 80 | – | – | – | – | – | – | – | – | – | 165 | 130 | 95 | 215 | 150 | 100 | 150 | 115 | 80 | |

| 4 | 165 | 150 | 115 | – | – | – | – | – | – | – | – | – | 180 | 165 | 115 | 245 | 195 | 130 | 165 | 150 | 100 | |

| H | 1 | 395 | 295 | 230 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||

Recommended Starting Speeds [SFM]

| Mill 4-12KT™ • Recommended Starting Speeds [SFM] | ||||||||||||||||||||||

| Grade | KC522M | KCK15 | KCK20B | KCPK30 | KCPM40 | KCSM40 | KC725M | |||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | 1085 | 935 | 885 | – | – | – | – | – | – | 1495 | 1295 | 1215 | 970 | 855 | 805 | 1150 | 1050 | 985 | 855 | 755 | 705 |

| 2 | 900 | 785 | 655 | – | – | – | – | – | – | 920 | 835 | 755 | 820 | 705 | 590 | 985 | 885 | 720 | 720 | 625 | 525 | |

| 3 | 835 | 705 | 575 | – | – | – | – | – | – | 835 | 755 | 675 | 755 | 640 | 525 | 920 | 785 | 640 | 655 | 560 | 460 | |

| 4 | 740 | 605 | 490 | – | – | – | – | – | – | 625 | 575 | 525 | 675 | 560 | 445 | 785 | 675 | 540 | 590 | 490 | 395 | |

| 5 | 605 | 560 | 490 | – | – | – | – | – | – | 855 | 755 | 690 | 560 | 510 | 445 | 655 | 590 | 525 | 490 | 445 | 395 | |

| 6 | 540 | 410 | 330 | – | – | – | – | – | – | 525 | 445 | 360 | 490 | 375 | 295 | 590 | 460 | 330 | 425 | 330 | 260 | |

| M | 1 | 675 | 590 | 540 | – | – | – | – | – | – | 675 | 605 | 510 | 640 | 560 | 510 | 855 | 625 | 375 | 560 | 490 | 445 |

| 2 | 605 | 525 | 425 | – | – | – | – | – | – | 605 | 525 | 460 | 575 | 490 | 410 | 755 | 560 | 345 | 510 | 425 | 360 | |

| 3 | 460 | 395 | 310 | – | – | – | – | – | – | 475 | 425 | 375 | 425 | 375 | 295 | 625 | 460 | 280 | 375 | 330 | 260 | |

| K | 1 | 755 | 675 | 605 | 1380 | 1265 | 1115 | 1180 | 950 | 805 | 970 | 870 | 785 | – | – | – | – | – | – | – | – | – |

| 2 | 590 | 525 | 490 | 1100 | 970 | 900 | 920 | 755 | 640 | 770 | 690 | 625 | – | – | – | – | – | – | – | – | – | |

| 3 | 490 | 445 | 395 | 920 | 820 | 755 | 690 | 575 | 460 | 640 | 575 | 525 | – | – | – | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 130 | 115 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 195 | 150 | 80 | 115 | 100 | 80 |

| 2 | 130 | 115 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 180 | 130 | 80 | 115 | 100 | 80 | |

| 3 | 165 | 130 | 80 | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 215 | 150 | 100 | 150 | 115 | 80 | |

| 4 | 165 | 150 | 115 | – | – | – | – | – | – | 165 | 150 | 115 | 180 | 165 | 115 | 245 | 195 | 130 | 165 | 150 | 100 | |

| H | 1 | 395 | 295 | 230 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||