Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Sign Out

Item(s)

successfully added to cart

View Cart

View Cart

Save on High-Quality Tools Before Time Runs Out

Shop Now!

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Holemaking

- /

- Solid Carbide Drills

- /

- HP Solid-Carbide Deep Hole Drills

- /

- KenDrill™ HPG • 20 x D • Internal Coolant • Straight Shank • Metric

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

KenDrill™ HPG • 20 x D • Internal Coolant • Straight Shank • Metric

Solid Carbide Deep Hole Drill for Steels and Cast Iron

Features and benefits

- HP solid carbide deep-hole drills with through coolant for steel, cast iron, stainless steel, high-temperature alloys, and non-ferrous materials.

- Application-specific SC drill for drilling holes up to 20 x D up to 4x faster than conventional HSS and gun drills.

- Broadest diameter range on the market from .0938–.6299″ (2,383–16mm).

- KMH-point geometry is available as a semi-standard, especially for crankshaft applications.

- KCPK20™ grade (B27_HPG) is an AlCrN-TiAlN-based coating provides outstanding wear resistance. New ultra-fine-grain carbide ensures process reliability at high feed rates in steel and iron.

Uses and application

Drilling: Stacked Plates

Drilling

Drilling: Inclined Exit

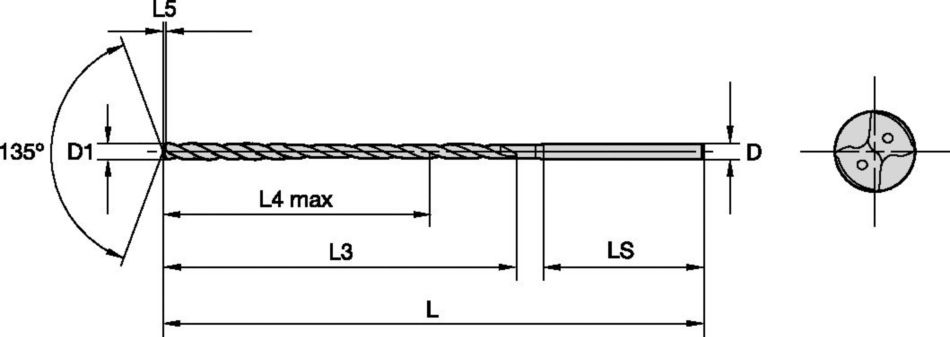

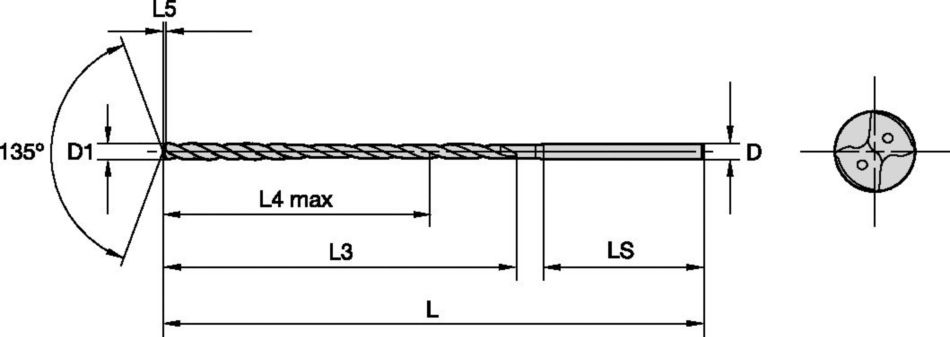

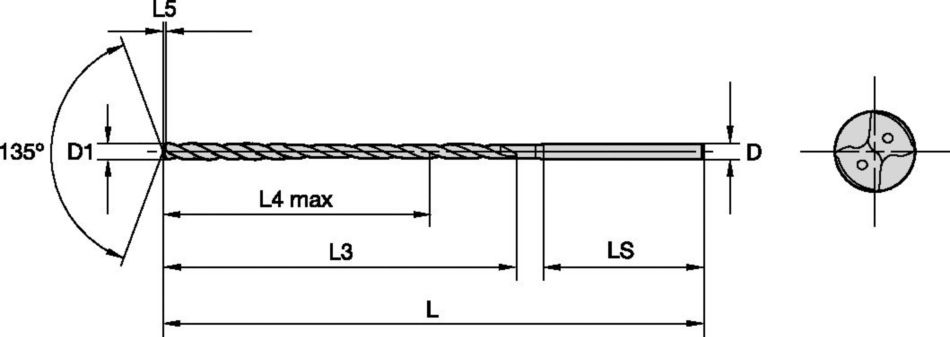

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

| Tolerance • Inch | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| .0394–.1181 | .0000/-.0004 | .0000/-.0006 |

|

|

.0002/.0006 | .0000/-.0003 |

|

|

.0002/.0008 | .0000/-.0004 |

|

|

.0003/.0010 | .0000/-.0004 |

|

|

.0003/.0011 | .0000/-.0005 |

| Tolerance • Metric | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| 1–3 | 0,000/-0,010 | 0,000/-0,014 |

|

|

0,004/0,016 | 0,000/-0,008 |

|

|

0,006/0,021 | 0,000/-0,009 |

|

|

0,007/0,025 | 0,000/-0,011 |

|

|

0,008/0,029 | 0,000/-0,013 |

Deep-Hole Drills • B27_HPG Series • Grade KCPK20™ • Through Coolant • Drill Diameters 3–16mm • Metric

| Material

|

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||

| Material

|

Cutting Speed

|

Inch | |||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | .551 | 5/8 .625 | |||

| P | 0 | 330 | 330 | 410 | IPR | .005–.006 | .006–.006 | .006–.008 | .008–.010 | .008–.012 | .010–.014 | .012–.016 | .013–.018 |

| 1 | 300 | 330 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 2 | 300 | 330 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 3 | 260 | 310 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 4 | 260 | 300 | 360 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 5 | 200 | 260 | 300 | IPR | .001–.004 | .002–.004 | .002–.004 | .002–.006 | .003–.007 | .004–.008 | .005–.009 | .006–.009 | |

| 6 | 200 | 230 | 260 | IPR | .001–.004 | .002–.004 | .002–.004 | .002–.006 | .003–.007 | .004–.008 | .005–.009 | .006–.009 | |

| M | 1 | 130 | 160 | 200 | IPR | .002–.003 | .002–.005 | .003–.006 | .004–.006 | .004–.006 | .005–.007 | .005–.007 | .006–.008 |

| 2 | 100 | 130 | 160 | IPR | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .004–.006 | .005–.007 | .005–.007 | |

| 3 | 100 | 130 | 160 | IPR | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .004–.006 | .004–.006 | .005–.007 | .005–.007 | |

| K | 1 | 260 | 330 | 390 | IPR | .006–.008 | .007–.008 | .008–.010 | .009–.013 | .011–.016 | .013–.018 | .015–.021 | .018–.023 |

| 2 | 260 | 300 | 330 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| 3 | 200 | 300 | 390 | IPR | .006–.007 | .006–.008 | .007–.010 | .009–.012 | .010–.015 | .012–.017 | .014–.019 | .016–.021 | |

| Material

|

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||

| Cutting Speed

|

Metric | ||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | |||

| P | 0 | 100 | 100 | 125 | mm/r | 0,13–0,15 | 0,14–0,16 | 0,15–0,21 | 0,19–0,26 | 0,21–0,31 | 0,26–0,36 | 0,30–0,41 | 0,34–0,46 |

| 1 | 90 | 100 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 2 | 90 | 100 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 80 | 95 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 4 | 80 | 90 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 5 | 60 | 80 | 90 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| 6 | 60 | 70 | 80 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| M | 1 | 40 | 50 | 60 | mm/r | 0,04–0,08 | 0,06–0,12 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | 0,14–0,19 |

| 2 | 30 | 40 | 50 | mm/r | 0,04–0,08 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| 3 | 30 | 40 | 50 | mm/r | 0,04–0,07 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| K | 1 | 80 | 100 | 120 | mm/r | 0,15–0,19 | 0,17–0,20 | 0,19–0,26 | 0,24–0,32 | 0,27–0,40 | 0,32–0,45 | 0,38–0,52 | 0,45–0,59 |

| 2 | 80 | 90 | 100 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 60 | 90 | 120 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

||||||||||||

| Cutting Speed

|

Metric | ||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Material

|

Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | ||

| P | 0 | 100 | 100 | 125 | mm/r | 0,13–0,15 | 0,14–0,16 | 0,15–0,21 | 0,19–0,26 | 0,21–0,31 | 0,26–0,36 | 0,30–0,41 | 0,34–0,46 |

| 1 | 90 | 100 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 2 | 90 | 100 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 80 | 95 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 4 | 80 | 90 | 110 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 5 | 60 | 80 | 90 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| 6 | 60 | 70 | 80 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,12–0,22 | 0,14–0,24 | |

| M | 1 | 40 | 50 | 60 | mm/r | 0,04–0,08 | 0,06–0,12 | 0,08–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | 0,14–0,19 |

| 2 | 30 | 40 | 50 | mm/r | 0,04–0,08 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| 3 | 30 | 40 | 50 | mm/r | 0,04–0,07 | 0,06–0,10 | 0,08–0,13 | 0,09–0,14 | 0,10–0,15 | 0,11–0,16 | 0,12–0,17 | 0,13–0,18 | |

| K | 1 | 80 | 100 | 120 | mm/r | 0,15–0,19 | 0,17–0,20 | 0,19–0,26 | 0,24–0,32 | 0,27–0,40 | 0,32–0,45 | 0,38–0,52 | 0,45–0,59 |

| 2 | 80 | 90 | 100 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |

| 3 | 60 | 90 | 120 | mm/r | 0,15–0,18 | 0,16–0,19 | 0,18–0,25 | 0,22–0,30 | 0,25–0,37 | 0,30–0,42 | 0,35–0,48 | 0,40–0,54 | |