Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Take your shop to the next level. See Promotions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Solid Carbide End Milling

- /

- High-Performance Solid Carbide End Mills

- /

- KOR5™ • High-Performance Solid Carbide End Mills

- /

- KOR5 DA

- /

- KOR5™ DA • Square End • 5 Flutes • 3 x D • Plain Shank • Inch

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

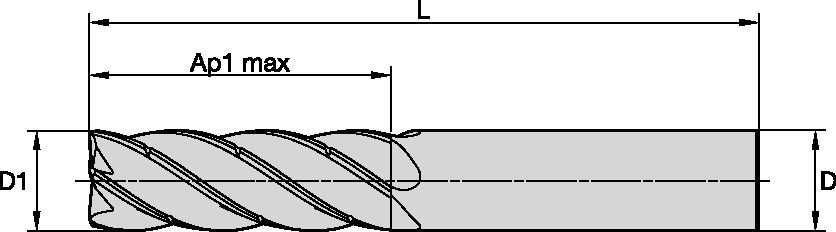

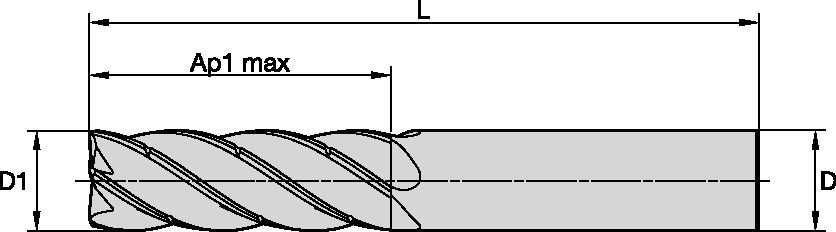

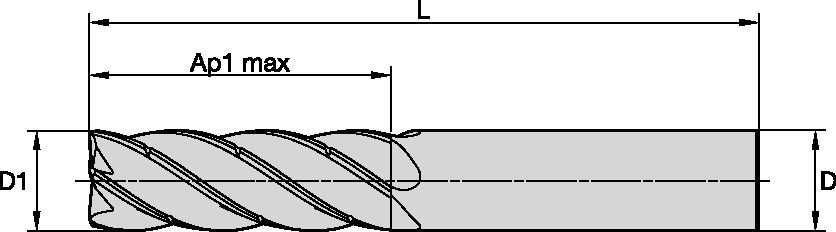

KOR5™ DA • Square End • 5 Flutes • 3 x D • Plain Shank • Inch

KOR5™ DA Solid Carbide End Mill for Dynamic Milling of Aluminum

Features and benefits

- Designed for trochoidal milling with low radial engagement and full length of cut.

- With chip splitters for ideal chip evacuation.

- Proprietary flute form reduces vibrations and improves tool life.

- Helix angle tailored to minimize vibration and optimize tool life.

- Front end geometry designed for maximum tool life in helical and ramping operations.

Uses and application

Trochoidal Milling

Ramping: 4°

Tool Dimensions: Flute Configuration: 5

Shank - Cylindrical Plain

Helix Angle: 35°

Corner Style: Corner Radius

Corner Style: Square End

Side Milling/Shoulder Milling: Roughing

Side Milling/Shoulder Milling: Finishing

| Ae/D1 | 2% | 5% | 10% | 20% | 30% | 40% | 50% | 100% |

| Max Ap | Ap1 Max | Ap1 Max | Ap1 Max | Ap1 Max | 2 x D1 | 1 x D1 | .5 x D1 | .25 x D1 |

| Feed Multiplier | 3.60 | 2.30 | 1.70 | 1.25 | 1.09 | 1.02 | 1.00 | .90 |

| Ae/D1 | 2% | 5% | 10% | 20% | 30% | 40% | 50% | 100% |

| Max Ap | Ap1 Max | Ap1 Max | Ap1 Max | Ap1 Max | 2 x D1 | 1 x D1 | 0,5 x D1 | 0,25 x D1 |

| Feed Multiplier | 3,60 | 2,30 | 1,70 | 1,25 | 1,09 | 1,02 | 1,00 | 0,90 |

|  |  | |||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | K600 | Recommended feed per tooth (IPT = inch/th) | |||||||||||

| D1 | |||||||||||||

| Malzeme grubu | A | B | Kesme hızı | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||

| ap | ae | ap | min | max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| N | 1 | 0.5 x D1 | 0.5 x D1 | 0.25 x D1 | 640 | – | 6560 | IPT | 0.0030 | 0.0050 | 0.0060 | 0.0080 | 0.0090 |

| 2 | 0.5 x D1 | 0.5 x D1 | 0.25 x D1 | 640 | – | 4920 | IPT | 0.0025 | 0.0045 | 0.0055 | 0.0070 | 0.0085 | |

| Malzeme grubu |  |  | K600 | Diş başına önerilen ilerleme (fz = mm/Diş) | |||||||||

| A | B | Kesme hızı; | D1 | ||||||||||

| ap | ae | ap | Min. | Maks. | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | |||

| N | 1 | 0,5 x D1 | 0,5 x D1 | 0,25 x D1 | 200 | – | 2000 | fz | 0,080 | 0,120 | 0,160 | 0,200 | 0,225 |

| 2 | 0,5 x D1 | 0,5 x D1 | 0,25 x D1 | 200 | – | 1500 | fz | 0,070 | 0,110 | 0,140 | 0,180 | 0,213 | |