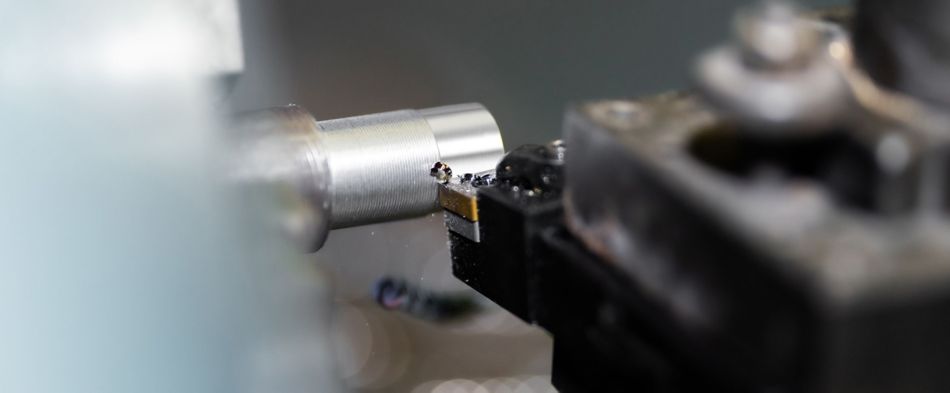

Minimalizujte prostoje a dosahujte kvalitních povrchů

KCU10B představuje vylepšenou verzi stávající sorty KCU10 od společnosti Kennametal, a má nově navržený vícevrstvý PVD povlak KENGold™, který usnadňuje obrábění z jednoho materiálu na druhý a zároveň při obrábění dosahuje konstantních výsledků. Tento nano-kompozitní povlak má vylepšenou přilnavost, která poskytuje lepší odolnost proti opotřebení a vylamování řezné hrany. Vylepšete své projekty zahrnující více materiálů a překonávejte termíny při práci na oceli, nerezu, litinách, žáruvzdorných slitinách a neželezných materiálech.

Představované produkty

- Negativní břitové destičky Kenloc™

- Pozitivní břitové destičky s upínáním šroubem

- Mikro zapichovací břitové destičky s upínáním šroubem

- Mikro závitovací břitové destičky s upínáním šroubem

- Pozitivní břitové destičky Kendex™

- Zapichovací břitové destičky Beyond Evolution

- A4™ zapichovací a soustružnické břitové destičky

- Břitové destičky Fix-Perfect™