Bem-vindo!

Confirme suas preferências

Atualizar preferências

Sugestões de produtos

Product Family suggestions

Kennametal ao seu serviço

Olá., User Name

Sua conta selecionada:

Existe um problema com a sua conta. Entre em contato com o suporte ao cliente.

Conta do vendedor Alterar conta

Conta de entrega Alterar conta

- Painel de controle

- Gerenciar pedidos

- Gerenciar canais

- Catálogo de endereços

Notificações

Marcar todas como lidas- Alterar senha

- Meu perfil

- Desconectar

Itens adicionado com sucesso ao carrinho

Ver o carrinho

Ver o carrinho

Aumente o volume gastando menos com nossas ofertas por tempo limitado! Compre agora

Kennametal ao seu serviço

Itens adicionado com sucesso ao carrinho

Ver o carrinho

Ver o carrinho

Editando solução

Adicionando solução

Nome da solução:{{SolutionName}}- Produtos

- /

- Mill 1-14™ End Mills • Screw-On • Métrico

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

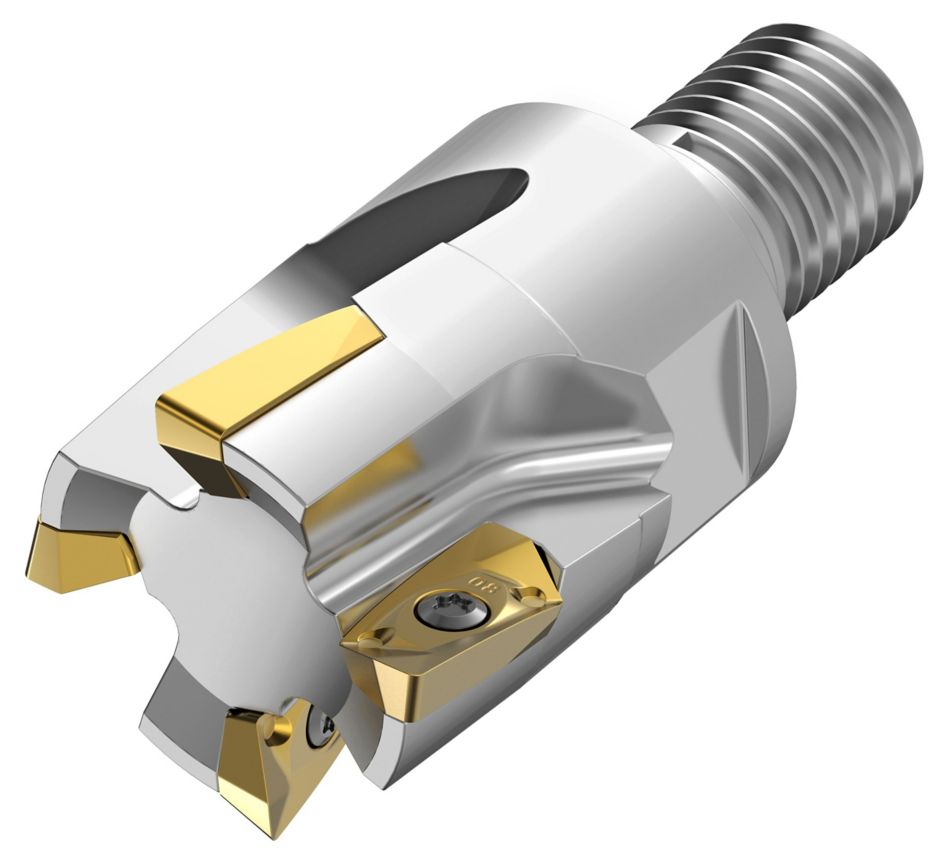

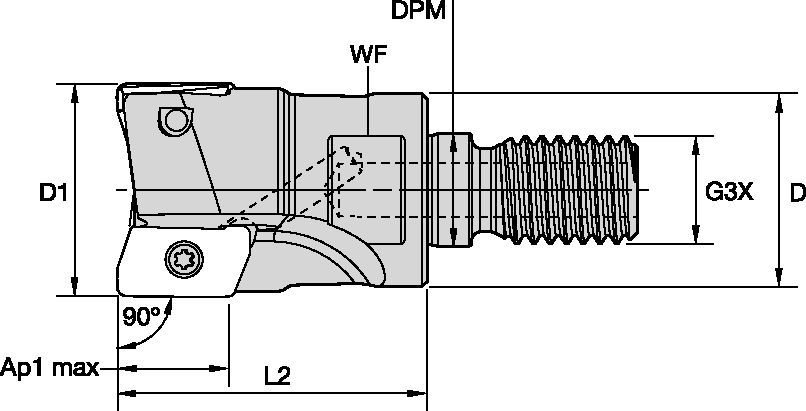

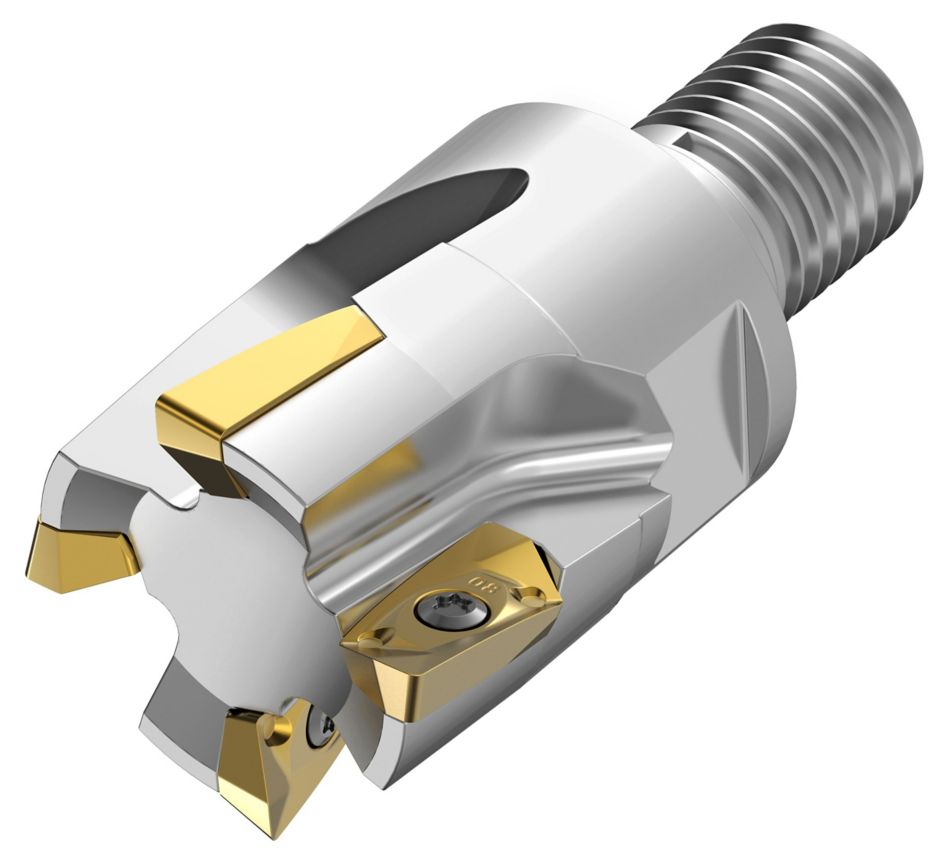

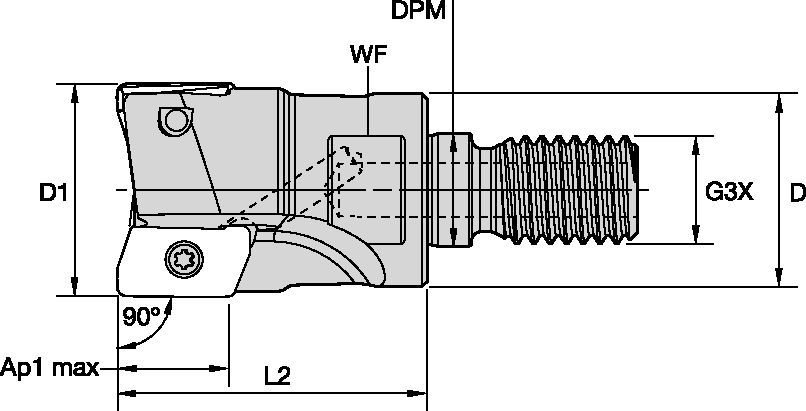

Mill 1-14™ End Mills • Screw-On • Métrico

Fresas de topo intercambiáveis

Características e benefícios

- Taxas agressivas de fresamento de rampa.

- Gera acabamento superficial superior.

- Paredes laterais de 90°.

- Capacidades de alta RPM.

Usos e aplicações

Fresamento de face

Fresamento helicoidal

Fresamento de rampa: blank

Abertura de canal: topo reto

Fresamento lateral/fresamento de canto: topo reto

Haste — Screw-On

Fresamento — Refrigeração interna

Fresamento de cavidade

| Malzeme grubu | Hafif işleme | Orta | Ağır işleme | |||

| P1–P2 | .E..GD | KCPM40 | .S..GD2 | KCPM40 | .E..HD2 | KCPM40 |

| P3–P4 | .E..GD | KCPM40 | .S..GD2 | KCPK30 | .E..HD2 | KCPK30 |

| P5–P6 | .E..GD | KC725M | .S..GD2 | KC725M | .E..HD2 | KC725M |

| M1–M2 | .E..LD | KC522M | .E..GD | KCSM40 | .E..HD2 | KC522M |

| M3 | .E..GD | KCSM40 | .S..GD2 | KCPM40 | .E..HD2 | KCPM40 |

| K1–K2 | .S..GD2 | KCK20B | .E..HD2 | KCK20B | .E..HD2 | KCK15 |

| K3 | .S..GD2 | KCK20B | .E..HD2 | KCK20B | .E..HD2 | KCK15 |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LDJ | KC422M |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LDJ | KC422M |

| S1–S2 | .E..GD | KC725M | .S..GD2 | KC725M | .E..HD2 | KC725M |

| S3 | .E..GD | KCSM40 | .S..GD2 | KC725M | .E..HD2 | KC725M |

| S4 | .E..GD | KCSM40 | .S..GD2 | KC725M | .E..HD2 | KC522M |

| H1 | – | – | – | – | – | – |

Avanços iniciais recomendados [mm]

| Mill 1-14™ • Recommended Starting Feeds [mm] | |||||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .F..LDJ | 0,12 | 0,46 | 0,82 | 0,08 | 0,33 | 0,59 | 0,06 | 0,25 | 0,44 | 0,06 | 0,22 | 0,38 | 0,05 | 0,20 | 0,35 |

| .E..LDJ | 0,12 | 0,47 | 0,82 | 0,08 | 0,34 | 0,59 | 0,06 | 0,26 | 0,44 | 0,06 | 0,22 | 0,39 | 0,05 | 0,20 | 0,35 |

| .E..LD | 0,12 | 0,46 | 0,81 | 0,09 | 0,33 | 0,58 | 0,07 | 0,25 | 0,43 | 0,06 | 0,22 | 0,38 | 0,05 | 0,20 | 0,35 |

| .E..GD | 0,17 | 0,52 | 0,89 | 0,12 | 0,38 | 0,64 | 0,09 | 0,28 | 0,48 | 0,08 | 0,24 | 0,42 | 0,07 | 0,22 | 0,38 |

| .S..GE | 0,23 | 0,51 | 0,89 | 0,17 | 0,37 | 0,64 | 0,13 | 0,27 | 0,48 | 0,11 | 0,24 | 0,42 | 0,10 | 0,22 | 0,38 |

| .S..GD | 0,23 | 0,50 | 0,88 | 0,17 | 0,36 | 0,63 | 0,13 | 0,27 | 0,47 | 0,11 | 0,24 | 0,41 | 0,10 | 0,22 | 0,38 |

| .S..GD2 | 0,23 | 0,50 | 0,88 | 0,17 | 0,36 | 0,63 | 0,13 | 0,27 | 0,47 | 0,11 | 0,24 | 0,41 | 0,10 | 0,22 | 0,38 |

| .E..HD | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 |

| .E..HD2 | 0,21 | 0,59 | 0,95 | 0,15 | 0,43 | 0,68 | 0,11 | 0,32 | 0,51 | 0,10 | 0,28 | 0,44 | 0,09 | 0,25 | 0,41 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

| Light | General | Heavy |

Avanços iniciais recomendados [mm]

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LDJ | 0,12 | 0,46 | 0,82 | 0,08 | 0,33 | 0,59 | 0,06 | 0,25 | 0,44 | 0,06 | 0,22 | 0,38 | 0,05 | 0,20 | 0,35 | .F..LDJ |

| .E..LDJ | 0,12 | 0,47 | 0,82 | 0,08 | 0,34 | 0,59 | 0,06 | 0,26 | 0,44 | 0,06 | 0,22 | 0,39 | 0,05 | 0,20 | 0,35 | .E..LDJ |

| .E..LD | 0,12 | 0,46 | 0,81 | 0,09 | 0,33 | 0,58 | 0,07 | 0,25 | 0,43 | 0,06 | 0,22 | 0,38 | 0,05 | 0,20 | 0,35 | .E..LD |

| .E..GD | 0,17 | 0,52 | 0,89 | 0,12 | 0,38 | 0,64 | 0,09 | 0,28 | 0,48 | 0,08 | 0,24 | 0,42 | 0,07 | 0,22 | 0,38 | .E..GD |

| .S..GE | 0,23 | 0,51 | 0,89 | 0,17 | 0,37 | 0,64 | 0,13 | 0,27 | 0,48 | 0,11 | 0,24 | 0,42 | 0,10 | 0,22 | 0,38 | .S..GE |

| .S..GD | 0,23 | 0,50 | 0,88 | 0,17 | 0,36 | 0,63 | 0,13 | 0,27 | 0,47 | 0,11 | 0,24 | 0,41 | 0,10 | 0,22 | 0,38 | .S..GD |

| .S..GD2 | 0,23 | 0,50 | 0,88 | 0,17 | 0,36 | 0,63 | 0,13 | 0,27 | 0,47 | 0,11 | 0,24 | 0,41 | 0,10 | 0,22 | 0,38 | .S..GD2 |

| .E..HD | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 | .E..HD |

| .E..HD2 | 0,21 | 0,59 | 0,95 | 0,15 | 0,43 | 0,68 | 0,11 | 0,32 | 0,51 | 0,10 | 0,28 | 0,44 | 0,09 | 0,25 | 0,41 | .E..HD2 |

| Mill 1-14™ • Recommended Starting Feeds [Inch] | |||||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| .F..LDJ | .005 | .013 | .023 | .003 | .009 | .017 | .003 | .007 | .013 | .002 | .006 | .011 | .002 | .006 | .010 |

| .E..LDJ | .005 | .017 | .028 | .003 | .012 | .020 | .003 | .009 | .015 | .002 | .008 | .013 | .002 | .007 | .012 |

| .E..LD | .005 | .016 | .028 | .004 | .012 | .020 | .003 | .009 | .015 | .002 | .008 | .013 | .002 | .007 | .012 |

| .E..GD | .007 | .019 | .032 | .005 | .013 | .023 | .004 | .010 | .017 | .003 | .009 | .015 | .003 | .008 | .014 |

| .S..GE | .009 | .020 | .032 | .007 | .014 | .023 | .005 | .011 | .017 | .004 | .009 | .015 | .004 | .009 | .014 |

| .S..GD | .009 | .020 | .032 | .007 | .014 | .023 | .005 | .011 | .017 | .004 | .009 | .015 | .004 | .009 | .014 |

| .S..GD2 | .009 | .020 | .032 | .007 | .014 | .023 | .005 | .011 | .017 | .004 | .009 | .015 | .004 | .009 | .014 |

| .E..HD | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 |

| .E..HD2 | .008 | .023 | .037 | .006 | .017 | .027 | .004 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||||||||||

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Leichte Bearbeitung | Allgemeine Anwendung | Schruppbearbeitung |

| Schneidkörper- Geometrie | Empfohlener Start-Vorschub pro Zahn (fz) im Verhältnis zur radialen Schnitttiefe (ae) in % | Schneidkörper- Geometrie | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LDJ | .005 | .019 | .033 | .003 | .013 | .023 | .003 | .010 | .018 | .002 | .009 | .015 | .002 | .008 | .014 | .F..LDJ |

| .E..LDJ | .005 | .019 | .033 | .003 | .014 | .024 | .003 | .010 | .018 | .002 | .009 | .015 | .002 | .008 | .014 | .E..LDJ |

| .E..LD | .005 | .018 | .032 | .004 | .013 | .023 | .003 | .010 | .017 | .002 | .009 | .015 | .002 | .008 | .014 | .E..LD |

| .E..GD | .007 | .020 | .035 | .005 | .015 | .025 | .004 | .011 | .019 | .003 | .010 | .016 | .003 | .009 | .015 | .E..GD |

| .S..GE | .009 | .020 | .035 | .007 | .014 | .025 | .005 | .011 | .019 | .004 | .009 | .017 | .004 | .009 | .015 | .S..GE |

| .S..GD | .009 | .020 | .035 | .007 | .014 | .025 | .005 | .011 | .019 | .004 | .009 | .016 | .004 | .009 | .015 | .S..GD |

| .S..GD2 | .009 | .020 | .035 | .007 | .014 | .025 | .005 | .011 | .019 | .004 | .009 | .016 | .004 | .009 | .015 | .S..GD2 |

| .E..HD | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .E..HD |

| .E..HD2 | .008 | .023 | .037 | .006 | .017 | .027 | .004 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .E..HD2 |

Velocidades recomendadas iniciais [m/min]

| Mill 1-14™ • Recommended Starting Speed [m/min] | ||||||||||||||||||||||||||||||||

| D = Dry Machining W = Wet Machining Y = Yes N = No Y, -20% = Yes, but reduce speed by 20% | KC410M | KC422M | KC522M | KC725M | KCK15 | KCK20B | KCPK30 | KCPM40 | KCSM30 | KCSM40 | ||||||||||||||||||||||

| Talaş kalınlığı hex mm | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||||||||||

| D | W | Kesme hızı (m/dk.) | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. |

| P | ||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | 330 | 285 | 270 | 260 | 230 | 215 | – | – | – | – | – | – | 455 | 395 | 370 | 295 | 260 | 245 | 370 | 320 | 300 | 350 | 320 | 300 |

| Y | Y, -20% | 2 | – | – | – | – | – | – | 275 | 240 | 200 | 220 | 190 | 160 | – | – | – | – | – | – | 280 | 255 | 230 | 250 | 215 | 180 | 305 | 270 | 220 | 300 | 270 | 220 |

| Y | Y, -20% | 3 | – | – | – | – | – | – | 255 | 215 | 175 | 200 | 170 | 140 | – | – | – | – | – | – | 255 | 230 | 205 | 230 | 195 | 160 | 285 | 240 | 195 | 280 | 240 | 195 |

| Y | Y, -20% | 4 | – | – | – | – | – | – | 225 | 185 | 150 | 180 | 150 | 120 | – | – | – | – | – | – | 225 | 185 | 160 | 205 | 170 | 135 | 250 | 205 | 165 | 240 | 205 | 165 |

| Y | Y, -20% | 5 | – | – | – | – | – | – | 185 | 170 | 150 | 150 | 135 | 120 | – | – | – | – | – | – | 190 | 170 | 150 | 170 | 155 | 135 | 205 | 190 | 165 | 200 | 180 | 160 |

| Y | Y, -20% | 6 | – | – | – | – | – | – | 165 | 125 | 100 | 130 | 100 | 80 | – | – | – | – | – | – | 160 | 135 | 110 | 150 | 115 | 90 | 185 | 140 | 110 | 180 | 140 | 100 |

| M | ||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | 205 | 180 | 165 | 170 | 150 | 135 | – | – | – | – | – | – | 205 | 185 | 155 | 195 | 170 | 155 | 225 | 180 | 170 | 260 | 210 | 185 |

| Y | Y, -20% | 2 | – | – | – | – | – | – | 185 | 160 | 130 | 155 | 130 | 110 | – | – | – | – | – | – | 185 | 160 | 140 | 175 | 150 | 125 | 205 | 160 | 135 | 235 | 180 | 145 |

| Y | Y, -20% | 3 | – | – | – | – | – | – | 140 | 120 | 95 | 115 | 100 | 80 | – | – | – | – | – | – | 145 | 130 | 115 | 130 | 115 | 90 | 155 | 125 | 95 | 175 | 145 | 110 |

| K | ||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | 230 | 205 | 185 | – | – | – | 420 | 385 | 340 | 360 | 290 | 245 | 295 | 265 | 240 | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | 180 | 160 | 150 | – | – | – | 335 | 295 | 275 | 280 | 230 | 195 | 235 | 210 | 190 | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | 150 | 135 | 120 | – | – | – | 280 | 250 | 230 | 210 | 175 | 140 | 195 | 175 | 160 | – | – | – | – | – | – | – | – | – |

| N | ||||||||||||||||||||||||||||||||

| N | Y | 1 | 1215 | 1080 | 995 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| N | Y | 2 | 1080 | 995 | 915 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| N | Y | 3 | 1080 | 995 | 915 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| S | ||||||||||||||||||||||||||||||||

| N | Y | 1 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 50 | 40 | 25 |

| N | Y | 2 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 45 | 40 | 30 | 55 | 40 | 25 |

| N | Y | 3 | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 55 | 45 | 30 | 65 | 45 | 30 |

| N | Y | 4 | – | – | – | – | – | – | 50 | 45 | 35 | 50 | 45 | 30 | – | – | – | – | – | – | 50 | 45 | 35 | 55 | 50 | 35 | 60 | 55 | 40 | 75 | 60 | 40 |

| H | ||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | 120 | 90 | 70 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 135 | 100 | 75 | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||

Velocidades recomendadas iniciais [m/min]

| Werkstoffgruppe | KC410M | KC422M | KC520M | KC522M | KC725M | KCK15 | KCPM20 | KCPK30 | |||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 330 | 285 | 270 | 260 | 230 | 215 | – | – | – | 550 | 485 | 450 | 455 | 395 | 370 |

| 2 | – | – | – | – | – | – | – | – | – | 275 | 240 | 200 | 220 | 190 | 160 | – | – | – | 340 | 310 | 275 | 280 | 255 | 230 | |

| 3 | – | – | – | – | – | – | – | – | – | 255 | 215 | 175 | 200 | 170 | 140 | – | – | – | 310 | 275 | 255 | 255 | 230 | 205 | |

| 4 | – | – | – | – | – | – | – | – | – | 225 | 185 | 150 | 180 | 150 | 120 | – | – | – | 230 | 215 | 190 | 190 | 175 | 160 | |

| 5 | – | – | – | – | – | – | – | – | – | 185 | 170 | 150 | 150 | 135 | 120 | – | – | – | 275 | 250 | 230 | 260 | 230 | 210 | |

| 6 | – | – | – | – | – | – | – | – | – | 165 | 125 | 100 | 130 | 100 | 80 | – | – | – | 190 | 170 | 145 | 160 | 135 | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | 205 | 180 | 165 | 170 | 150 | 135 | – | – | – | 225 | 200 | 175 | 205 | 185 | 155 |

| 2 | – | – | – | – | – | – | – | – | – | 185 | 160 | 130 | 155 | 130 | 110 | – | – | – | 205 | 175 | 160 | 185 | 160 | 140 | |

| 3 | – | – | – | – | – | – | – | – | – | 140 | 120 | 95 | 115 | 100 | 80 | – | – | – | 160 | 145 | 125 | 145 | 130 | 115 | |

| K | 1 | – | – | – | – | – | – | 270 | 245 | 215 | 230 | 205 | 185 | – | – | – | 420 | 385 | 340 | 360 | 325 | 295 | 295 | 265 | 240 |

| 2 | – | – | – | – | – | – | 210 | 190 | 175 | 180 | 160 | 150 | – | – | – | 335 | 295 | 275 | 285 | 255 | 235 | 235 | 210 | 190 | |

| 3 | – | – | – | – | – | – | 175 | 160 | 145 | 150 | 135 | 120 | – | – | – | 280 | 250 | 230 | 240 | 215 | 200 | 195 | 175 | 160 | |

| N | 1–2 | 1215 | 1080 | 995 | 1075 | 945 | 875 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 1080 | 995 | 915 | 945 | 875 | 760 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | 70 | 50 | 35 | 60 | 45 | 30 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds and Feeds [SFM]

| Mill 1-14™ • Recommended Starting Speeds [SFM] | ||||||||||||||||||||||||||||||||

| D = Dry Machining W = Wet Machining Y = Yes N = No Y, -20% = Yes, but reduce speed by 20% | KC410M | KC422M | KC522M | KC725M | KCK15 | KCK20B | KCPK30 | KCPM40 | KCSM30 | KCSM40 | ||||||||||||||||||||||

| Chip Thickness hex Inch | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||||||||||

| D | W | Kesme hızı | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. | Başlangıç | Başlangıç | Min. |

| P | ||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | 1085 | 935 | 885 | 855 | 755 | 705 | – | – | – | – | – | – | 1495 | 1295 | 1215 | 970 | 855 | 805 | 1215 | 1050 | 985 | 1150 | 1050 | 985 |

| Y | Y, -20% | 2 | – | – | – | – | – | – | 900 | 785 | 655 | 720 | 625 | 525 | – | – | – | – | – | – | 920 | 835 | 755 | 820 | 705 | 590 | 1000 | 885 | 720 | 985 | 885 | 720 |

| Y | Y, -20% | 3 | – | – | – | – | – | – | 835 | 705 | 575 | 655 | 560 | 460 | – | – | – | – | – | – | 835 | 755 | 675 | 755 | 640 | 525 | 935 | 785 | 640 | 920 | 785 | 640 |

| Y | Y, -20% | 4 | – | – | – | – | – | – | 740 | 605 | 490 | 590 | 490 | 395 | – | – | – | – | – | – | 740 | 605 | 525 | 675 | 560 | 445 | 820 | 675 | 540 | 785 | 675 | 540 |

| Y | Y, -20% | 5 | – | – | – | – | – | – | 605 | 560 | 490 | 490 | 445 | 395 | – | – | – | – | – | – | 625 | 560 | 490 | 560 | 510 | 445 | 675 | 625 | 540 | 655 | 590 | 525 |

| Y | Y, -20% | 6 | – | – | – | – | – | – | 540 | 410 | 330 | 425 | 330 | 260 | – | – | – | – | – | – | 525 | 445 | 360 | 490 | 375 | 295 | 605 | 460 | 360 | 590 | 460 | 330 |

| M | ||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | 675 | 590 | 540 | 560 | 490 | 445 | – | – | – | – | – | – | 675 | 605 | 510 | 640 | 560 | 510 | 740 | 590 | 560 | 855 | 690 | 605 |

| Y | Y, -20% | 2 | – | – | – | – | – | – | 605 | 525 | 425 | 510 | 425 | 360 | – | – | – | – | – | – | 605 | 525 | 460 | 575 | 490 | 410 | 675 | 525 | 445 | 770 | 590 | 475 |

| Y | Y, -20% | 3 | – | – | – | – | – | – | 460 | 395 | 310 | 375 | 330 | 260 | – | – | – | – | – | – | 475 | 425 | 375 | 425 | 375 | 295 | 510 | 410 | 310 | 575 | 475 | 360 |

| K | ||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | 755 | 675 | 605 | – | – | – | 1380 | 1265 | 1115 | 1180 | 950 | 805 | 970 | 870 | 785 | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | 590 | 525 | 490 | – | – | – | 1100 | 970 | 900 | 920 | 755 | 640 | 770 | 690 | 625 | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | 490 | 445 | 395 | – | – | – | 920 | 820 | 755 | 690 | 575 | 460 | 640 | 575 | 525 | – | – | – | – | – | – | – | – | – |

| N | ||||||||||||||||||||||||||||||||

| N | Y | 1 | 3985 | 3545 | 3265 | 3525 | 3100 | 2870 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| N | Y | 2 | 3545 | 3265 | 3000 | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| N | Y | 3 | 3545 | 3265 | 3000 | 3100 | 2870 | 2495 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| S | ||||||||||||||||||||||||||||||||

| N | Y | 1 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 165 | 130 | 80 |

| N | Y | 2 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 150 | 130 | 100 | 180 | 130 | 80 |

| N | Y | 3 | – | – | – | – | – | – | 165 | 130 | 80 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 180 | 150 | 100 | 215 | 150 | 100 |

| N | Y | 4 | – | – | – | – | – | – | 165 | 150 | 115 | 165 | 150 | 100 | – | – | – | – | – | – | 165 | 150 | 115 | 180 | 165 | 115 | 195 | 180 | 130 | 245 | 195 | 130 |

| H | ||||||||||||||||||||||||||||||||

| Y | Y, -20% | 1 | – | – | – | – | – | – | 395 | 295 | 230 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 445 | 330 | 245 | – | – | – |

| Y | Y, -20% | 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Y | Y, -20% | 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||

Recommended Starting Speeds [SFM]

| Werkstoffgruppe | KC410M | KC422M | KC520M | KC522M | KC725M | KCK15 | KCPM20 | KCPK30 | |||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 1080 | 940 | 880 | 860 | 750 | 700 | – | – | – | 1810 | 1590 | 1470 | 1485 | 1300 | 1210 |

| 2 | – | – | – | – | – | – | – | – | – | 900 | 790 | 660 | 720 | 630 | 530 | – | – | – | 1120 | 1010 | 910 | 920 | 830 | 750 | |

| 3 | – | – | – | – | – | – | – | – | – | 830 | 700 | 580 | 660 | 560 | 460 | – | – | – | 1010 | 910 | 830 | 830 | 750 | 680 | |

| 4 | – | – | – | – | – | – | – | – | – | 740 | 610 | 490 | 590 | 490 | 390 | – | – | – | 760 | 700 | 630 | 620 | 575 | 520 | |

| 5 | – | – | – | – | – | – | – | – | – | 610 | 550 | 490 | 490 | 440 | 390 | – | – | – | 910 | 820 | 750 | 850 | 760 | 690 | |

| 6 | – | – | – | – | – | – | – | – | – | 540 | 410 | 330 | 430 | 330 | 260 | – | – | – | 630 | 550 | 475 | 520 | 450 | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | 670 | 590 | 540 | 560 | 490 | 450 | – | – | – | 730 | 655 | 570 | 680 | 600 | 515 |

| 2 | – | – | – | – | – | – | – | – | – | 610 | 520 | 430 | 510 | 430 | 360 | – | – | – | 670 | 580 | 520 | 610 | 530 | 460 | |

| 3 | – | – | – | – | – | – | – | – | – | 460 | 400 | 310 | 380 | 330 | 260 | – | – | – | 530 | 475 | 410 | 475 | 430 | 380 | |

| K | 1 | – | – | – | – | – | – | 880 | 800 | 710 | 750 | 680 | 600 | – | – | – | 1380 | 1255 | 1115 | 1180 | 1070 | 960 | 965 | 875 | 780 |

| 2 | – | – | – | – | – | – | 690 | 620 | 580 | 590 | 530 | 490 | – | – | – | 1095 | 975 | 910 | 940 | 840 | 770 | 770 | 690 | 630 | |

| 3 | – | – | – | – | – | – | 580 | 520 | 470 | 490 | 440 | 400 | – | – | – | 920 | 815 | 750 | 790 | 700 | 650 | 645 | 575 | 530 | |

| N | 1–2 | 3990 | 3550 | 3270 | 3520 | 3100 | 2870 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 3580 | 3270 | 3000 | 3100 | 2870 | 2500 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 130 | 120 | 90 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 130 | 120 | 90 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 170 | 130 | 90 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | 230 | 170 | 120 | 200 | 150 | 100 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Exemplos de aplicação

| Mill 1-14™ • Ramping Angles [mm] | |||||

| Kesici uç tipi | Kesme çapı | maks rampa açısı | DH min [mm] - (min hole diameter) | DH min (minumum delik çapı) | DHI min (minimum tabanı düz olan delik çapı) |

| Mill 1-14 | 20 | 16˚ | 23,74 | 40 | 35,62 |

| Mill 1-14 | 25 | 11˚ | 33,75 | 50 | 44,44 |

| Mill 1-14 | 32 | 7˚ | 47,80 | 64 | 59,79 |

| Mill 1-14 | 40 | 5˚ | 63,76 | 80 | 75,22 |

| Mill 1-14 | 40 | 5˚ | 64,00 | 80 | 75,47 |

| Mill 1-14 | 50 | 4˚ | 83,96 | 100 | 96,05 |

| Mill 1-14 | 63 | 3˚ | 109,93 | 126 | 121,47 |

| Mill 1-14 | 80 | 2˚ | 143,91 | 160 | 155,47 |

| Mill 1-14 | 100 | 1˚ | 183,89 | 200 | 199,47 |

| Mill 1-14 | 125 | 1˚ | 233,88 | 250 | 245,47 |

| Mill 1-14 | 160 | 1˚ | 303,88 | 320 | 315,47 |

Exemplos de aplicação

| Wendeschneidplatten-Ausführung | Nenn- durch- messer | Max. Tauchwinkel | min. Bohrungs- durchmesser (DH min) | max. Flachbohrungs- durchmesser (DH1 max) | max. Durchmesser |

| Mill 1-14™ | 32 | 5,4˚ | 47,80 | 59,79 | 64 |

| Mill 1-14™ | 40 | 3,8˚ | 64,00 | 75,47 | 80 |

| Mill 1-14™ | 50 | 2,7˚ | 83,96 | 96,05 | 100 |

| Mill 1-14™ | 63 | 1,9˚ | 109,93 | 121,47 | 126 |

Application Examples

| insert style | cutting diameter | max ramp angle | DH min (min hole diameter) | DHI min (min flat-bottomed hole diameter) | max diameter (no flat bottom) |

| Mill-1, 14mm | .625 | 25˚ | .625 | 1.065 | 1.25 |

| Mill-1, 14mm | .750 | 18˚ | .869 | 1.130 | 1.50 |

| Mill-1, 14mm | .875 | 13˚ | 1.113 | 1.562 | 1.75 |

| Mill-1, 14mm | .970 | 11˚ | 1.300 | 1.752 | 1.94 |

| Mill-1, 14mm | 1.000 | 10˚ | 1.360 | 1.812 | 2.00 |

| Mill-1, 14mm | 1.250 | 7˚ | 1.862 | 2.312 | 2.50 |

| Mill-1, 14mm | 1.500 | 6˚ | 2.361 | 2.812 | 3.00 |

| Mill-1, 14mm | 1.250 | 7˚ | 1.873 | 2.322 | 2.50 |

| Mill-1, 14mm | 1.500 | 5˚ | 2.370 | 2.822 | 3.00 |

| Mill-1, 14mm | 2.000 | 4˚ | 3.368 | 3.822 | 4.00 |

| Mill-1, 14mm | 2.500 | 3˚ | 4.367 | 4.822 | 5.00 |

| Mill-1, 14mm | 3.000 | 2˚ | 5.366 | 5.822 | 6.00 |

| Mill-1, 14mm | 4.000 | 2˚ | 7.366 | 7.822 | 8.00 |

Application Examples

| Wendeschneidplatten-Ausführung | Nenn- durch- messer | Max. Tauchwinkel | DH min (min Bohrungsdurchmesser) | DHI min (max. Flachbohrungs-Durchmesser) | max. Bohrungsdurchmesser (keine Flachbohrung) |

| Mill 1-14 | 1.25 | 5.4˚ | 1.862 | 2.312 | 2.5 |

| Mill 1-14 | 1.50 | 4.0˚ | 2.370 | 2.822 | 3 |

| Mill 1-14 | 2.00 | 2.6˚ | 3.368 | 3.822 | 4 |

| Mill 1-14 | 2.50 | 1.9˚ | 4.367 | 4.822 | 5 |