Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Sign Out

Item(s)

successfully added to cart

View Cart

View Cart

Enter to Win a 1-Year FREE Subscription to Fusion

Enter Today!

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Turning

- /

- Profiling

- /

- Top Notch™ Profiling

- /

- Top Notch™ Inserts

- /

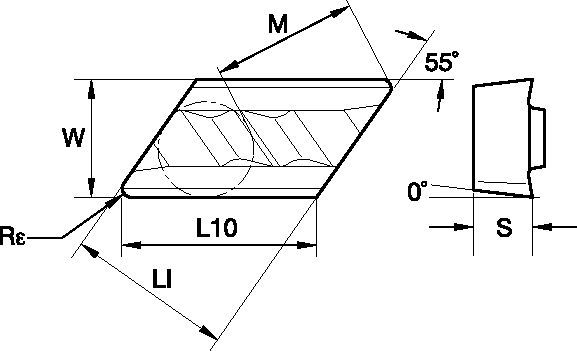

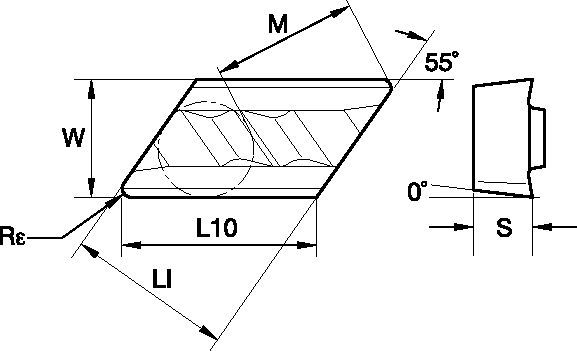

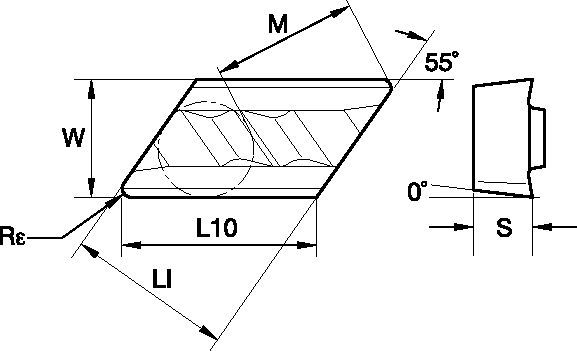

- KNGX • NPR/L

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

KNGX • NPR/L

Inserts