Vítejte

Potvrďte své předvolby

Aktualizovat předvolby

Návrhy produktů

Product Family suggestions

Kennametal k vašim službám

Zakaznicke centrum

Vítejte, User Name

Vámi vybraný účet:

Vyskytl se problém s vaším účtem. Kontaktujte prosím zákaznickou podporu.

Účet kupujícího

Změnit účet

Účet pro příjemce zásilky

Změnit účet

- Ovládací panel

- Spravovat objednávky

- Spravovat kanály

- Adresář

-

Oznámení

Označit vše jako přečtené - Změnit heslo

- Můj profil

- Odhlásit se

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Frézujte více za méně s našimi časově omezenými nabídkami!

Nakupujte nyní.

Kennametal k vašim službám

Zakaznicke centrum

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Úprava řešení

Přidání řešení

Název řešení: {{SolutionName}}- Produkty

- /

- SNMG

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

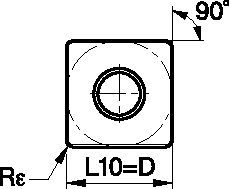

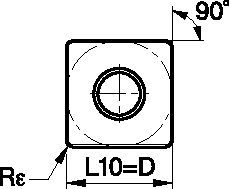

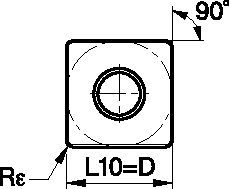

SNMG

Břitové destičky Kenloc™

Vlastnosti a výhody

- Včetně sort Beyond™ Drive™.