Product Similar To:

TM731 . Metric . Through Coolant

Solid Carbide Thread Mills • Blind and Through Holes

Material Number4135827

ISO Catalog IDTM731M100X150R2DHAANSI Catalog IDTM731M100X150R2DHA

- K Cast Iron

- N Non-Ferrous

Threading: Through Hole

Threading: Blind Hole

Counter Sinking/ Stroke Chamfering

Through Coolant: Axial: Tapping

HM

Drilling Depth: 2x

Manufacturer’s Specs: M

Manufacturer’s Specs: MF

Drilling: Blind

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

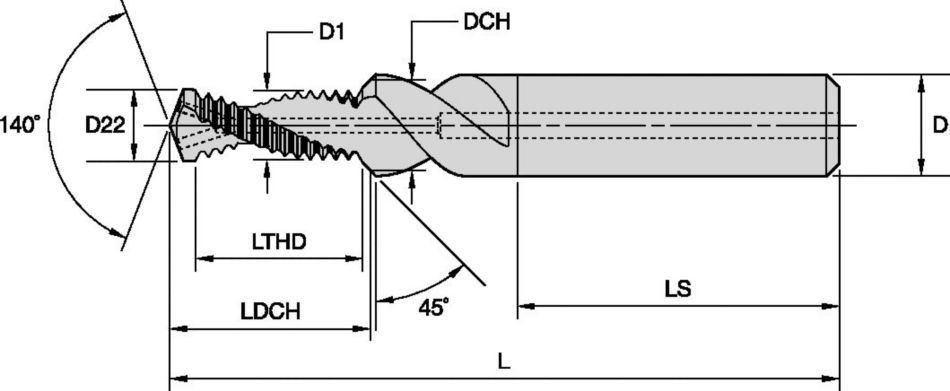

| Material Number | 4135827 |

| ISO Catalog ID | TM731M100X150R2DHA |

| ANSI Catalog ID | TM731M100X150R2DHA |

| Grade | KCU32 |

| [TDZ] Thread Diameter Size | M10X1.5 |

| [D22] Cut Diameter 2 | 8.5 mm |

| [D22] Cut Diameter 2 | 0.3346 in |

| [D1] Effective Cutting Diameter | 8.2 mm |

| [D1] Effective Cutting Diameter | 0.3228 in |

| [DCH] Chamfer Diameter | 10.3 mm |

| [DCH] Chamfer Diameter | 0.4055 in |

| [LTHD] Thread Length | 19.59 mm |

| [LTHD] Thread Length | 0.7713 in |

| [LDCH] Chamfer Length-Tool Front | 23.65 mm |

| [LDCH] Chamfer Length-Tool Front | 0.9311 in |

| [L] Overall Length | 79 mm |

| [L] Overall Length | 3.1102 in |

| [LS] Shank Length | 45 mm |

| [LS] Shank Length | 1.7717 in |

| [D] Adapter / Shank / Bore Diameter | 12 mm |

| [D] Adapter / Shank / Bore Diameter | 0.4724 in |

| Number of Effective Cutting Edges on Face | 2 |

Workpiece Materials

- Cast Iron

- Non-Ferrous

Uses and application

Threading: Through Hole

Threading: Blind Hole

Counter Sinking/ Stroke Chamfering

Through Coolant: Axial: Tapping

HM

Drilling Depth: 2x

Manufacturer’s Specs: M

Manufacturer’s Specs: MF

Drilling: Blind

Grades

KCU32

Coated carbide. PVD — Fine-grain carbide substrate with high hardness TiCN coating. Universal grade for thread milling most materials.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

Application Data

| Material |  | |||||||||||

| Drill, Chamfer, and Thread Mill TM731 | ||||||||||||

| Cutting Speed | Drilling | Milling | ||||||||||

| Recommended Feed by Diameter | Feed/Tooth by Diameter | |||||||||||

| Range | ||||||||||||

| Min | Starting Value | Max | – | 6mm | 6 | 10 | – | 6mm | 6 | 10 | ||

| K | 1 | 130 | 175 | 230 | mm/r | 0,10 | 0,16 | 0,30 | mm/r | 0,05 | 0,07 | 0,10 |

| N | 2 | 270 | 300 | 330 | mm/r | 0,15 | 0,25 | 0,34 | mm/r | 0,06 | 0,08 | 0,12 |

| 3 | 140 | 150 | 170 | mm/r | 0,15 | 0,25 | 0,34 | mm/r | 0,06 | 0,08 | 0,12 | |

| 4 | 270 | 300 | 330 | mm/r | 0,15 | 0,25 | 0,34 | mm/r | 0,06 | 0,08 | 0,12 | |

| 5 | 110 | 120 | 130 | mm/r | 0,12 | 0,20 | 0,32 | mm/r | 0,06 | 0,08 | 0,12 | |

| ||||||||||||

| Drill, Chamfer, and Thread Mill TM731 | ||||||||||||

| Drilling | Milling | |||||||||||

| Cutting Speed | ||||||||||||

| Range | Recommended Feed by Diameter | Feed/Tooth by Diameter | ||||||||||

| Material | Min | Starting Value | Max | – | 6 mm | 6-10 mm | 10-16 mm | – | 6 mm | 6-10 mm | 10-16 mm | |

| K | 1 | 130 | 175 | 230 | mm/dev | 0,10 | 0,16 | 0,30 | mm/dev | 0,05 | 0,07 | 0,10 |

| 2 | 270 | 300 | 330 | mm/dev | 0,15 | 0,25 | 0,34 | mm/dev | 0,06 | 0,08 | 0,12 | |

| N | 3 | 140 | 150 | 170 | mm/dev | 0,15 | 0,25 | 0,34 | mm/dev | 0,06 | 0,08 | 0,12 |

| 4 | 270 | 300 | 330 | mm/dev | 0,15 | 0,25 | 0,34 | mm/dev | 0,06 | 0,08 | 0,12 | |

| 5 | 110 | 120 | 130 | mm/dev | 0,12 | 0,20 | 0,32 | mm/dev | 0,06 | 0,08 | 0,12 | |

Application Data

Tolerance

| shank tolerance | |

| D | tolerance h6 + / - |

| 6 | +0, -0,008 |

| 8 | +0, -0,009 |

| 12 | +0, -0,011 |

| 20 | +0, -0,013 |

I have read and accepted the Terms & Conditions of use