For US and Canadian customers, a tariff surcharge will be added to your order for metal cutting products.

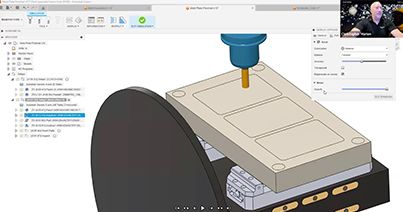

- Webinar: Unlock Efficiency with Autodesk Fusion and Kennametal Tooling SolutionsDiscover how to import Kennametal tooling data into Autodesk Fusion and optimize your manufacturing processes with our in-depth webinar.Discover how to import Kennametal tooling data into Autodesk Fusion and optimize your manufacturing processes with our in-depth webinar.

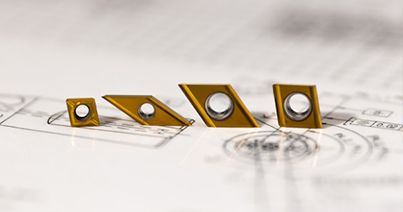

- Celebrating Kennametal’s Legacy in TurningCelebrate Kennametal's long history in turning and discover why they have become a leader in manufacturing. Plus, learn about some of the newest innovations.Celebrate Kennametal's long history in turning and discover why they have become a leader in manufacturing. Plus, learn about some of the newest innovations.

- Essential Tips for Troubleshooting Indexable MillingEffective troubleshooting in indexable milling requires a systematic approach to identify and resolve issues. Here’s some advice on common problems.Effective troubleshooting in indexable milling requires a systematic approach to identify and resolve issues. Here’s some advice on common problems.

- Precision Machining with TopSwiss™ MBS: A Comprehensive GuideTopSwiss™ MBS stands out as a solution used across industries including defense, medical, transportation, fluid transfer and small parts machining. Learn more.TopSwiss™ MBS stands out as a solution used across industries including defense, medical, transportation, fluid transfer and small parts machining. Learn more.

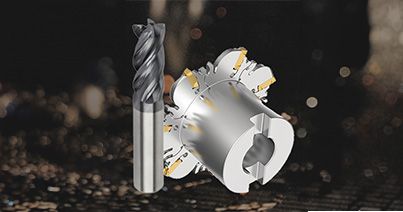

- Grades and coatings for Solid Carbide End Mills Improving the performance of solid carbide end mills is a crucial element for getting the best out of your machining operations. Find out about coatings and grades.Improving the performance of solid carbide end mills is a crucial element for getting the best out of your machining operations. Find out about coatings and grades.

- Tech Tip: Reducing Chatter & Vibration in End MillingChatter and vibration are common challenges that can turn a smooth operation into a noisy, inefficient mess. Learn some practical tips to make your operations smoother and more efficient.Chatter and vibration are common challenges that can turn a smooth operation into a noisy, inefficient mess. Learn some practical tips to make your operations smoother and more efficient.

- TopSwiss Turning Inserts and Small Parts Machining Machining small parts calls for high precision, tight tolerances and excellent surface finishes. Kennametal’s TopSwiss Turning Inserts tooling is designed to meet those demands.Machining small parts calls for high precision, tight tolerances and excellent surface finishes. Kennametal’s TopSwiss Turning Inserts tooling is designed to meet those demands.

- Kennametal Showcases Innovations Globally Kennametal has been taking the spotlight globally by showcasing the latest innovations at tradeshows including IMTS Chicago, AMB Stuttgart, & JIMTOF Tokyo.Kennametal has been taking the spotlight globally by showcasing the latest innovations at tradeshows including IMTS Chicago, AMB Stuttgart, & JIMTOF Tokyo.

- Legacy Meets Innovation: Kennametal Introduces New ProductsWe are celebrating new cutting-edge solutions across several platforms including TopSwiss™ MBS for turning, while reflecting on our journey of continuous improvement. Join us!We are celebrating new cutting-edge solutions across several platforms including TopSwiss™ MBS for turning, while reflecting on our journey of continuous improvement. Join us!

- Kennametal Celebrates World EV Day with Innovative Tooling SolutionsIn honor of World EV Day, Kennametal continues to innovate with the precision tools necessary to drive change for a sustainable, cleaner future. Find out more about our e-mobility tooling solutions.In honor of World EV Day, Kennametal continues to innovate with the precision tools necessary to drive change for a sustainable, cleaner future. Find out more about our e-mobility tooling solutions.

- Celebrating Aviation Day with Kennametal’s Aerospace InnovationsIn honor of Aviation Day, explore some great tooling solutions to help you navigate this complex industry so you can take your projects to new heights.In honor of Aviation Day, explore some great tooling solutions to help you navigate this complex industry so you can take your projects to new heights.

- Buying Guide: Composite Materials Machining SolutionsWhen manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.When manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.

- Micromachining: Exploring the Growth of Medical InnovationExplore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.Explore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.

- Choose the Right Toolholder for Your Operations Choosing the right toolholder is critical for achieving precise and efficient machining results. Explore the fundamentals of toolholders and find out what you should know before choosing the right one for your operations.Choosing the right toolholder is critical for achieving precise and efficient machining results. Explore the fundamentals of toolholders and find out what you should know before choosing the right one for your operations.

- Essential Tips on Tool Holder Maintenance Mastering tool holder maintenance with these expert tips ensures precise machining, extends tool life, and enhances productivity. Learn more.Mastering tool holder maintenance with these expert tips ensures precise machining, extends tool life, and enhances productivity. Learn more.

- Electric Vehicles: Driving the Charge in Metal CuttingAs electric vehicles drive demand to create innovative tooling solutions, we’ll explore the benefits, changes, and some innovative tooling in the market.As electric vehicles drive demand to create innovative tooling solutions, we’ll explore the benefits, changes, and some innovative tooling in the market.

- Tips to Reduce Waste in MachiningWould you like to be more cost-effective when machining? Find out some helpful tips on how to reduce waste and save on production costs.Would you like to be more cost-effective when machining? Find out some helpful tips on how to reduce waste and save on production costs.

- PCD Tool Reconditioning by Kennametal: Extend the Life of Your Tools PCD tools are used for their exceptional hardness, wear resistance, and durability. Explore PCD tool reconditioning benefits and how to extend their life.PCD tools are used for their exceptional hardness, wear resistance, and durability. Explore PCD tool reconditioning benefits and how to extend their life.

- Buying Guide: The Importance of Ramping in MillingOne of the most critical aspects of milling a workpiece is ramping. Learn about key areas on what to look do before your ramping operations.One of the most critical aspects of milling a workpiece is ramping. Learn about key areas on what to look do before your ramping operations.

- Drill Bits for Stainless Steel – Kennametal Buying Guide Looking for the best drill bits for stainless steel? Learn how to choose the right drill bits and keep them maintained for optimal holemaking operations.Looking for the best drill bits for stainless steel? Learn how to choose the right drill bits and keep them maintained for optimal holemaking operations.

- Mastering Precision: The Anatomy of a Toolholder SystemToolholding plays a pivotal role in machining. Explore the anatomy of a toolholding system and get some tips on how to use them effectively.Toolholding plays a pivotal role in machining. Explore the anatomy of a toolholding system and get some tips on how to use them effectively.

- 10 Tips for Milling TitaniumMachining titanium can be a challenge, but with the right techniques and tools, you can achieve high-quality results. Discover 10 tips for milling titanium.Machining titanium can be a challenge, but with the right techniques and tools, you can achieve high-quality results. Discover 10 tips for milling titanium.

- Different Types of Thread TapsLearn about the different types of thread taps and how to choose the right one for your operation. Discover basic tips for using thread taps effectively.Learn about the different types of thread taps and how to choose the right one for your operation. Discover basic tips for using thread taps effectively.

- Essential Metal Cutting Safety TipsPreventing injuries during metal-cutting operations is essential for maintaining a healthy workforce. Read for helpful tips on how to protect your workforce.Preventing injuries during metal-cutting operations is essential for maintaining a healthy workforce. Read for helpful tips on how to protect your workforce.

- Machining Guide: Thread Milling vs. TappingMost internal screw threads are produced using tapping or thread milling. Learn when to use one method over the other and explore a few tips on each.Most internal screw threads are produced using tapping or thread milling. Learn when to use one method over the other and explore a few tips on each.

- Buying Guide: Selecting Carbide Inserts for MetalworkingIndexable turning, milling, and drilling tools are often the best choice for productive, cost-effective machining. Learn more about carbide inserts.Indexable turning, milling, and drilling tools are often the best choice for productive, cost-effective machining. Learn more about carbide inserts.

- Machinist's Guide: Why Bi-Metal Holesaws Aren't Always the Best Option for Drilling HolesHolemaking is the most common of all machining operations. It's also one of the more challenging. Without the right cutting tool, productivity and part quality will suffer while manufacturing costs soar. Here are some tips on avoiding these problems and selecting the right tool for the job.Holemaking is the most common of all machining operations. It's also one of the more challenging. Without the right cutting tool, productivity and part quality will suffer while manufacturing costs soar. Here are some tips on avoiding these problems and selecting the right tool for the job.

- Buying Guide: The Basics of BoringBoring uses a single-point or sometimes a dual-head cutting tool to remove material in a manner that’s quite similar to external turning. Learn more.Boring uses a single-point or sometimes a dual-head cutting tool to remove material in a manner that’s quite similar to external turning. Learn more.

- Buying Guide: Unraveling the Why and How of Flat Bottom Drilling Flat bottom holes are a common feature in a variety of machined parts, but accurately and efficiently machining them can be challenging. Read more!Flat bottom holes are a common feature in a variety of machined parts, but accurately and efficiently machining them can be challenging. Read more!

- Machinist’s Guide: Face Milling vs. Peripheral Milling—What’s the Difference?If you’ve ever wondered about the difference between face milling and peripheral milling, you’ve come to the right place. This article explores this important machining topic and offers tips on which technique is best for specific applications.If you’ve ever wondered about the difference between face milling and peripheral milling, you’ve come to the right place. This article explores this important machining topic and offers tips on which technique is best for specific applications.

- Machining Guide: Tungsten Carbide vs. Cobalt Drill Bits Carbide, cobalt, high-speed steel (HSS)—there's no shortage of high-quality drill bits available, but which one is best for your application? Learn more.Carbide, cobalt, high-speed steel (HSS)—there's no shortage of high-quality drill bits available, but which one is best for your application? Learn more.

- How to Choose the Right Carbide Drill BitHolemaking is the most common of all machining operations. Here are some tips on avoiding these problems and selecting the right tool for the job.Holemaking is the most common of all machining operations. Here are some tips on avoiding these problems and selecting the right tool for the job.

- Machining Guide: Cutting Fluid Tips for Holemaking OperationsHolemaking is challenging work. This article provides some CNC coolant application tips for making drilling operations easy and productive. Read more.Holemaking is challenging work. This article provides some CNC coolant application tips for making drilling operations easy and productive. Read more.

- Milling Machine Basics: Types, Classifications, and Cutting ToolsMilling machines rank among the most important of all industrial machinery, due to their ability to quickly produce accurate parts and part features in practically any metal or plastic. Here’s a quick primer on their function, the types of milling machines available, and the best cutting tools for milling.Milling machines rank among the most important of all industrial machinery, due to their ability to quickly produce accurate parts and part features in practically any metal or plastic. Here’s a quick primer on their function, the types of milling machines available, and the best cutting tools for milling.

- Buying Guide: Four Things to Know About Milling Cutter SelectionGiven the huge variety of solid and indexable milling cutters available online today, it can be challenging to choose the right one for a machining application. Here’s a quick primer to get you started.Given the huge variety of solid and indexable milling cutters available online today, it can be challenging to choose the right one for a machining application. Here’s a quick primer to get you started.

- Printing the Future of E-Vehicle Manufacturing... TodayKennametal's stator bore tool leverages the design and flexibility of additive manufacturing for machining EV components. Learn more.Kennametal's stator bore tool leverages the design and flexibility of additive manufacturing for machining EV components. Learn more.

- KenTIP™ FS: When Power Meets FlexibilityKenTIP FS's intelligent interface & features enable this Kennametal modular drill to match the productivity of solid carbide drills. Learn more.KenTIP FS's intelligent interface & features enable this Kennametal modular drill to match the productivity of solid carbide drills. Learn more.

- KOR™5 DA: How to Make Aluminum (Chips) FlyKennametal’s KOR5 DA solid end mill has high feed rates & MRR. Meet the engineers who worked on the design, and learn how to cut aluminum like a king!Kennametal’s KOR5 DA solid end mill has high feed rates & MRR. Meet the engineers who worked on the design, and learn how to cut aluminum like a king!