Keep Cutting Fluids Current

For starters, many shops upgrade their machine tools and other machining technology without considering whether they’re using the best possible cutting fluids. Filling the sump with the sulfur-based oils or water-soluble fluids of yesteryear are a little like putting unleaded fuel into a high-performance sportscar—it might run for a while, but you'll eventually run into performance problems.

Cutting fluids experts will tell you that replacing these outdated cutting fluids with modern, premium grades of semi-synthetics helps to reduce costs and improve productivity. This is mainly due to these fluids’ high-lubricity esters, which eliminate the need for chlorinated paraffin or sulfur-based EP compounds.

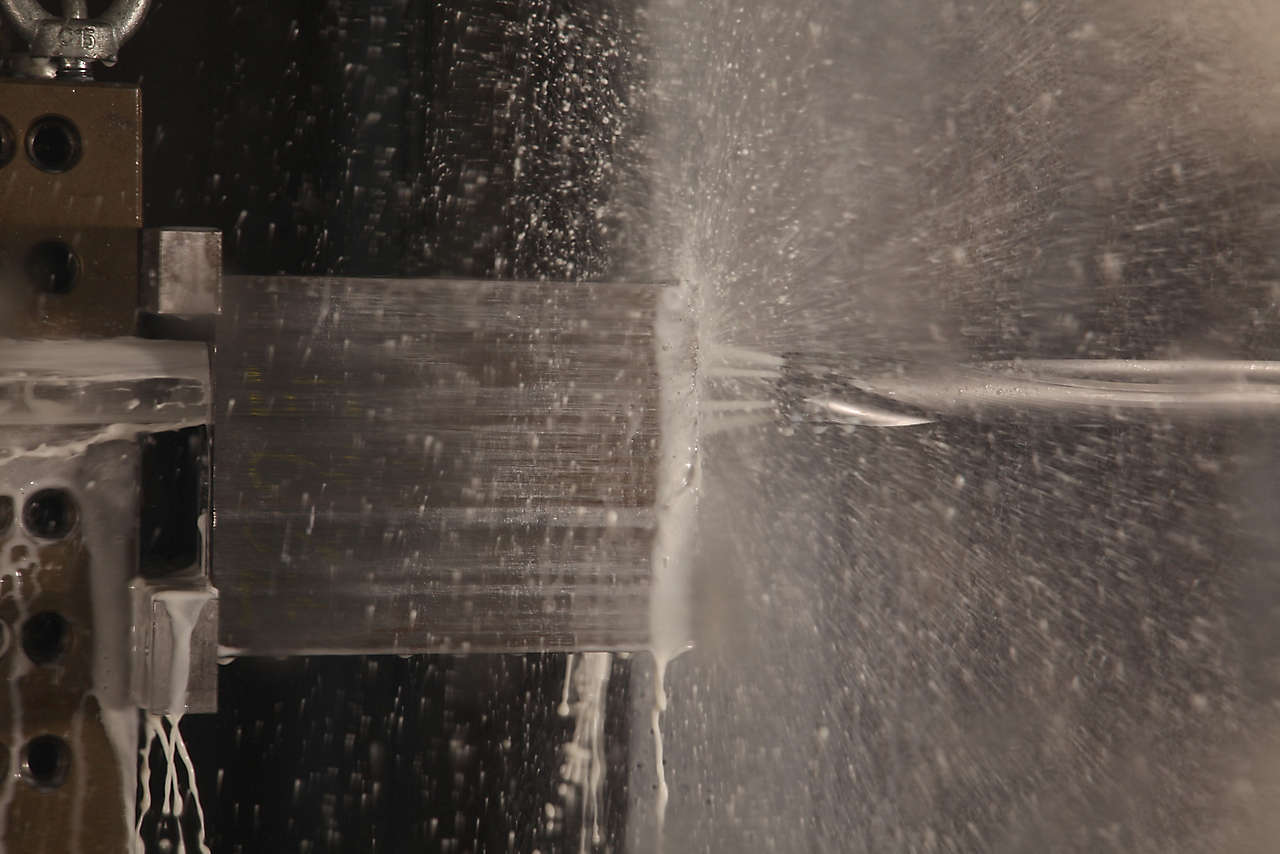

These esters create a tight boundary layer around oil droplets, keeping them intact during metalworking operations. It also enhances their lubricity and thus reduces wear on cutters and machinery. And because they're less likely to break down under pressure at today’s higher cutting speeds and feedrates. Finally, and just as important is their greater friendliness to workers and the environment alike.

Today’s cutting fluids offer other advantages as well. Since they’re more efficient at lubrication, less concentrate is needed when mixing up a fresh batch of coolant. This cuts operating costs while limiting the amount of “food" for bacteria lurking in any machine tool sump, resulting in a nicer-smelling shop and no “Monday morning stink.”

With that, they tend to reduce the amount of time spent on fluid maintenance and sump cleaning. And since these high-ester fluids increase the emulsion’s water content, they enhance its cooling ability, a benefit that’s critical during holemaking.