Exceptional Wear Resistance & Unmatched Performance

Everyday Kennametal abrasive blasting nozzles meet the challenges of demanding environments. Our abrasive blast nozzles are backed by outstanding customer service and technical support.

Designed to deliver improved productivity and enhanced hearing protection, the Blast Ninja™ is a premium nozzle, providing customers with a military grade product that is compliant with OSHA guidelines.

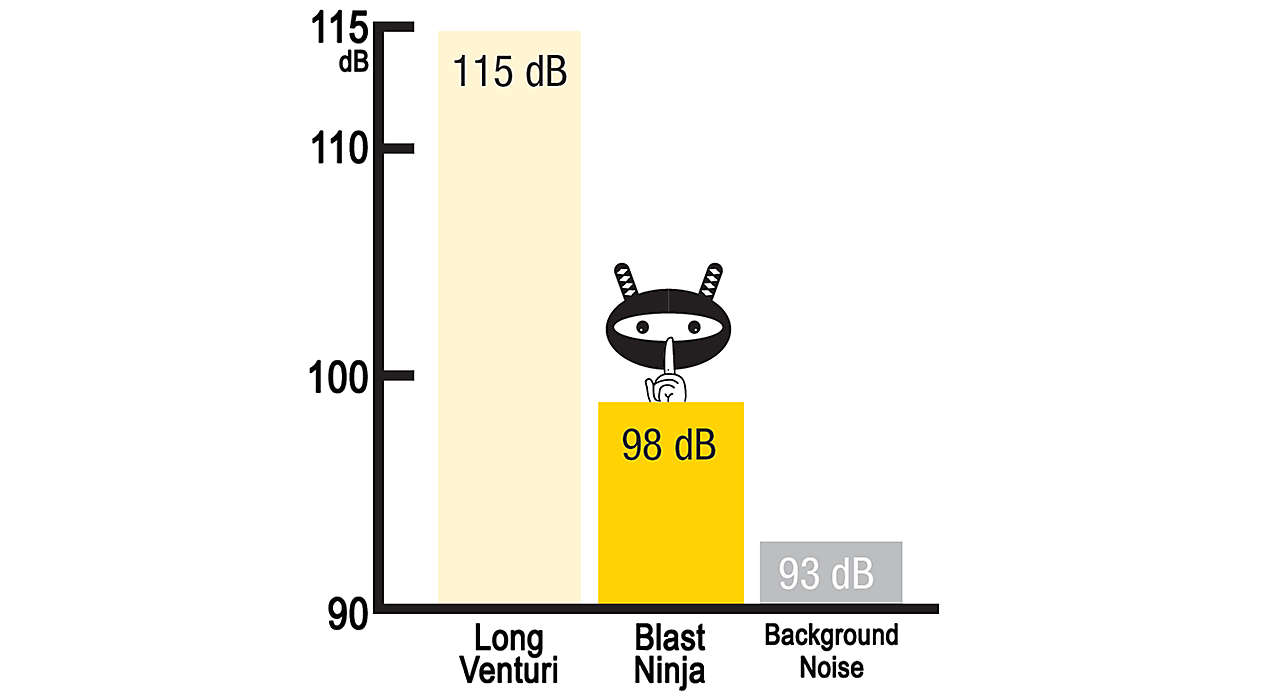

A game-changer for the abrasive blasting industry, the Blast Ninja reduces air exit velocity while maintaining particle velocity, resulting in a significant reduction in noise production at the source while maintaining blasting production.

Blast Ninja nozzles set the new standard in performance, worker safety, and productivity.

- Durable carbide insert construction

- Expected nozzle life with expendable abrasives is up to 500 hours, similar to a conventional tungsten carbide nozzle.

- Strip rate equal to, or better than standard venturi nozzles

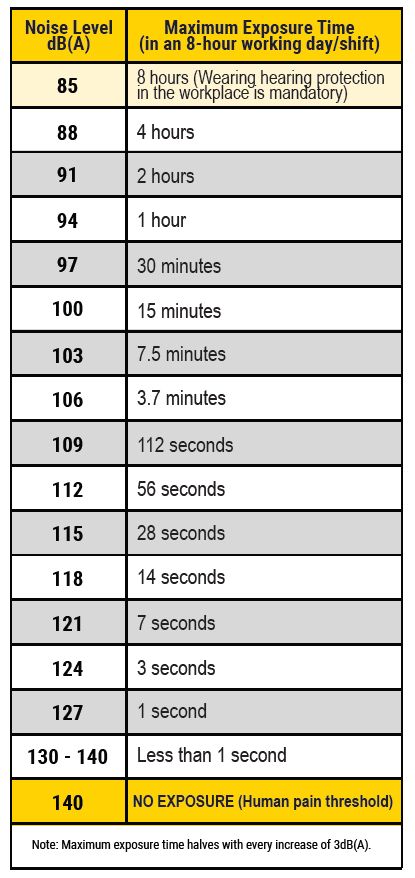

- Reduction in hazardous noise exposure by up to 17 dB(A)

- Greatly reduced incidence of operator hearing damage

- Reduced OSHA noise citations