Understanding CNC Machining: The Basics

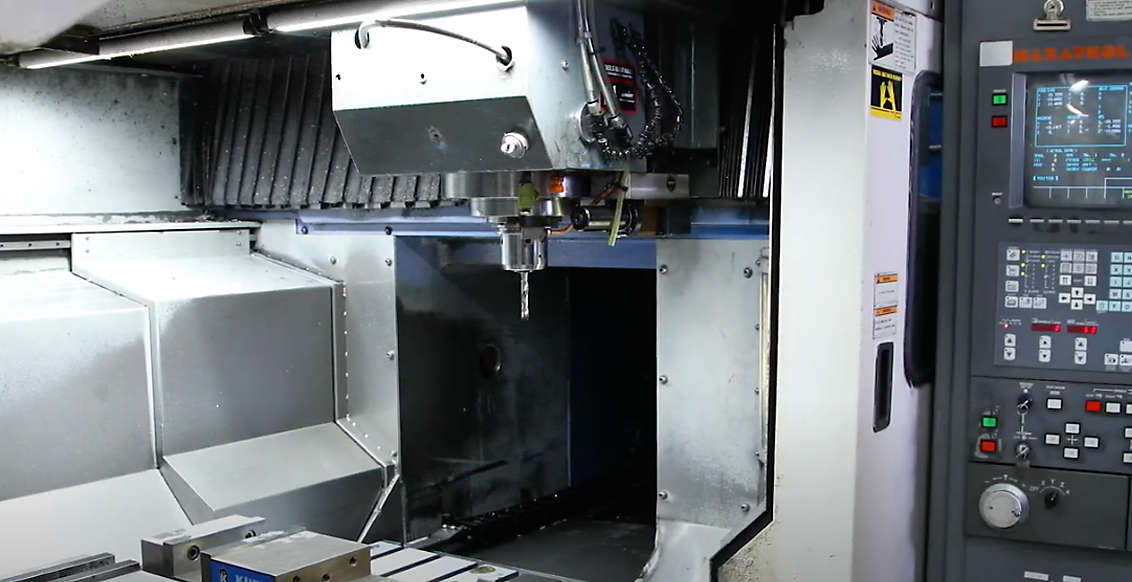

CNC machining stands for Computer Numerical Control machining. It is a manufacturing process that involves the use of computer software to control machine tools such as lathes, mills, routers, and grinders.

CNC machines are highly precise and can produce complex shapes and designs with ease, making them popular in industries such as aerospace and automotive, and other industrial sectors. This machining process involves three main components: the computer system, the machine tool, and the cutting tool. The computer system controls the machine tool and the cutting tool to perform the required tasks accurately and precisely.

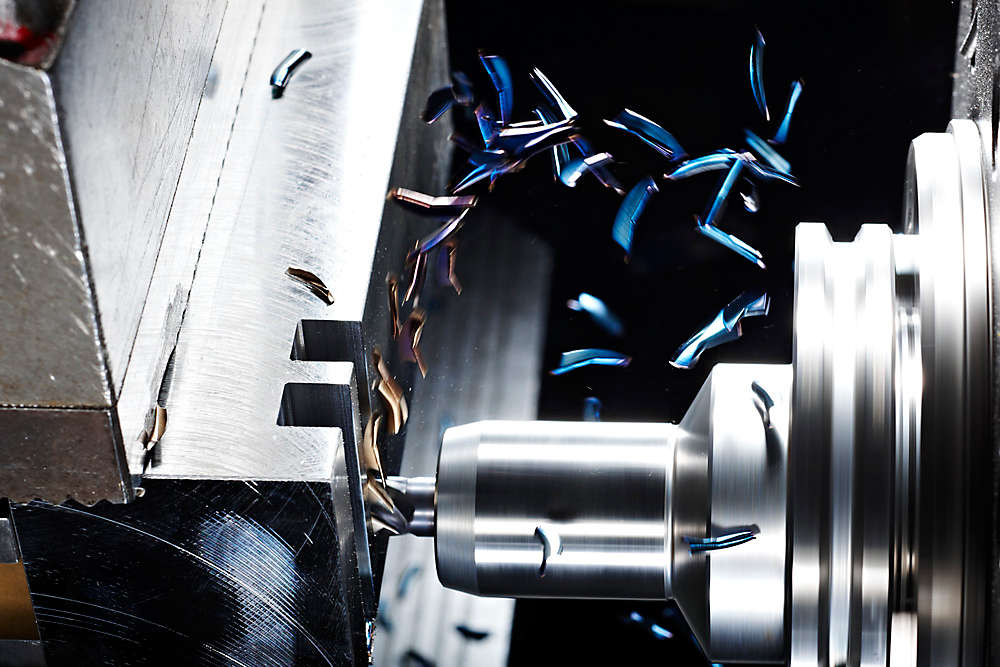

The cutting tool is typically a drill bit, end mill, or router bit, which is designed to cut through various materials such as metals, plastics, and composites. The machine tool is the physical equipment that performs the cutting, drilling, or milling operation.

CNC machines can be programmed to perform a wide range of operations, including drilling, cutting, milling, grinding, and turning. The computer system reads the program code and converts it into precise movements of the machine tool and cutting tool to produce the desired result.

CNC machining is a precise manufacturing process that involves computer software to control machine tools. It is widely used in various industries and can produce complex shapes and designs with ease. Understanding the basics of CNC machining is essential for anyone looking to use this technology to improve their business operations.

The Benefits of CNC Machining for Your Business

CNC machining offers numerous benefits for businesses looking to improve their manufacturing operations. Here are some of the key benefits of CNC machining:

- Improved precision and accuracy: CNC machines are highly precise and can produce complex shapes and designs with ease. They can perform the same task repeatedly, ensuring consistency in the final product.

- Increased productivity: CNC machines can operate continuously, 24/7, without the need for human intervention. This means that they can produce more parts in a shorter time frame, increasing productivity and output.

- Reduced waste: CNC machines are highly efficient and can produce parts with minimal waste. This reduces the cost of materials and improves the sustainability of the manufacturing process.

- Cost-effective: While CNC machines can be expensive to purchase and maintain, they can save businesses money overall. CNC machines can operate continuously, requiring less human labor, and producing parts with higher precision, reducing the need for expensive rework or scrap.

- Versatility: CNC machines can be programmed to perform a wide range of operations, including drilling, cutting, milling, and grinding, making them highly versatile.

CNC machining offers several benefits for businesses looking to improve their manufacturing operations. From improved precision and accuracy to increased productivity and reduced waste, CNC machines can save businesses money overall and improve the quality of their products.

How CNC Machining Improves Efficiency and Reduces Waste

CNC machines can significantly improve efficiency and reduce waste in the manufacturing process. Here are some of the ways that CNC machining can achieve these benefits:

- Increased automation: CNC machines are highly automated, which means that they can operate continuously without the need for human intervention. This eliminates downtime and speeds up the manufacturing process.

- Improved accuracy and precision: CNC machines are highly accurate and precise, which means that they can produce parts that meet the required specifications consistently. This eliminates the need for expensive rework and reduces waste.

- Reduced setup time: CNC machines can be programmed to perform multiple tasks, which reduces the need for manual setup between operations. This reduces setup time and increases the efficiency of the manufacturing process.

- Consistency: CNC machines can produce identical parts consistently, which reduces the likelihood of errors and inconsistencies in the manufacturing process.

- Reduced scrap: CNC machines can produce parts with minimal waste, which reduces the cost of materials and improves the sustainability of the manufacturing process.

- Improved flexibility: CNC machines can be programmed to produce a wide range of parts, which makes them highly flexible. This reduces the need for multiple machines and improves the efficiency of the manufacturing process.

From increased automation and improved accuracy to reduced setup time and improved flexibility, CNC machines can help businesses save money and produce high-quality parts consistently.

Saving Your Organization Money with CNC Machining: A Cost-Benefit Analysis

CNC machines can be a significant investment for businesses, but it can also provide significant cost savings overall. Here is a cost-benefit analysis of how CNC machining can save your organization money:

- Labor costs: CNC machines can operate continuously without the need for human intervention, reducing the need for manual labor. This can result in significant labor cost savings over time.

- Production costs: CNC machines can produce parts with high precision and accuracy, reducing the need for expensive rework or scrap. This can reduce production costs and improve efficiency.

- Tooling costs: CNC machines can use a variety of cutting tools, including end mills and drills, which can reduce the need for specialized tools and equipment. This can reduce tooling costs and increase flexibility in the manufacturing process.

- Material costs: CNC machines can produce parts with minimal waste, reducing the amount of material needed for each part. This can reduce material costs and improve sustainability.

- Time savings: CNC machines can operate continuously, producing parts faster than manual labor. This can reduce lead times and improve time-to-market, resulting in increased revenue and profitability.

While CNC machining can require a significant upfront investment, the long-term cost savings can be significant. By reducing labor and production costs, tooling and material costs, and improving efficiency and time-to-market, CNC machining can save your organization money and increase profitability over time.

Related Articles

- Buying Guide: Composite Materials Machining SolutionsWhen manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.When manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.

- Micromachining: Exploring the Growth of Medical InnovationExplore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.Explore micromachining and its relation to medical devices, the tools and materials used, and why manufacturing plays a vital role in this area.

- Choose the Right Toolholder for Your Operations Choosing the right toolholder is critical for achieving precise and efficient machining results. Explore the fundamentals of toolholders and find out what you should know before choosing the right one for your operations.Choosing the right toolholder is critical for achieving precise and efficient machining results. Explore the fundamentals of toolholders and find out what you should know before choosing the right one for your operations.

- Electric Vehicles: Driving the Charge in Metal CuttingAs electric vehicles drive demand to create innovative tooling solutions, we’ll explore the benefits, changes, and some innovative tooling in the market.As electric vehicles drive demand to create innovative tooling solutions, we’ll explore the benefits, changes, and some innovative tooling in the market.