Vítejte

Potvrďte své předvolby

Aktualizovat předvolby

Návrhy produktů

Product Family suggestions

Kennametal k vašim službám

Zakaznicke centrum

Vítejte,

User Name

Vámi vybraný účet:

Vyskytl se problém s vaším účtem. Kontaktujte prosím zákaznickou podporu.

Účet kupujícího

Změnit účet

Účet pro příjemce zásilky

Změnit účet

- Ovládací panel

- Spravovat objednávky

- Spravovat kanály

- Adresář

-

Oznámení

Označit vše jako přečtené - Změnit heslo

- Můj profil

- Odhlásit se

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Frézujte více za méně s našimi časově omezenými nabídkami!

Nakupujte nyní.

Kennametal k vašim službám

Zakaznicke centrum

Položka (položky)

úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Úprava řešení

Přidání řešení

Název řešení: {{SolutionName}}- Produkty

- /

- Nástroje pro obrábění kovů

- /

- Frézování

- /

- Frézování čelními válcovými frézami ze slinutých karbidů

- /

- Vrtáky s vysokým výkonem z pevného karbidu

- /

- KOR6™ DT • High-Performance Solid Carbide End Mills

- /

- KOR6™ DT • S rádiusem • 6-břité • 3 X D • Válcová stopka • Metrické

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

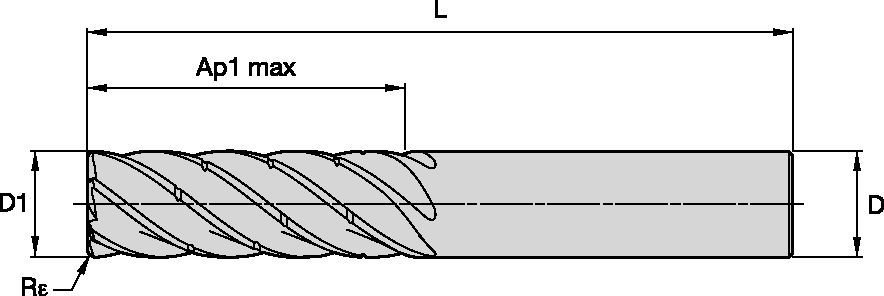

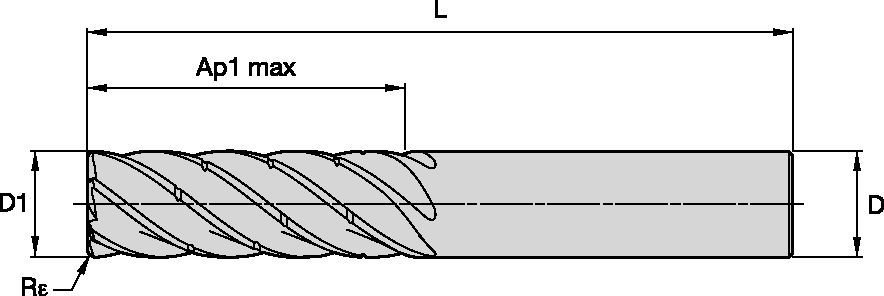

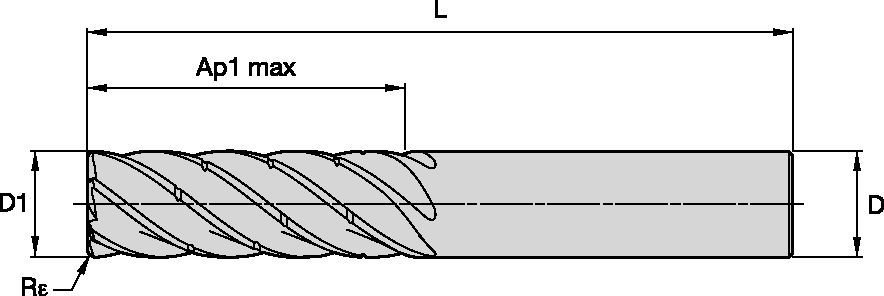

KOR6™ DT • S rádiusem • 6-břité • 3 X D • Válcová stopka • Metrické

Karbidové stopkové frézy KOR6™ DT pro dynamické frézování titanu.

Vlastnosti a výhody

- Trochoidní frézování s malým radiálním záběrem a celou délkou řezné části..

- Dělič třísky pro ideální odvod třísek.

- Patentovaný tvar drážky snižuje vibrace a zlepšuje životnost nástroje.

- Úhel šroubovice minimalizuje vibrace a optimalizuje životnost nástroje.

- Geometrie čela je navržena pro maximální životnost nástroje při kruhové interpolaci a zavrtávání.

- Možnost zavrtávání a zapichování.

Použití

Trochoidal Milling

Ramping: Blank

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 6

Shank - Cylindrical Plain

Helix Angle: 38°

Corner Style: Corner Radius

KOR6™ DS • 6-břité • 3 x D • Tabulka korekčního koeficientu pro posuvy • Metrické

| Ae/D1 | 0.50% | 1.00% | 1.50% | 2.00% | 4.00% | 5.00% | 8.00% | 10.00% | |

| Speed factor | Kv | 2.15 | 2.11 | 2.07 | 1.48 | 1.11 | 1.07 | 1.04 | 1.00 |

| Feed factor | KFz | 1.65 | 1.53 | 1.47 | 1.41 | 1.35 | 1.29 | 1.18 | 1.00 |

KOR6™ DT • 6-břité • 3 x D • Řezné podmínky • Metrické

|  |

||||||||||||

| Side Milling (A) | KCSM15 | Recommended feed per tooth (fz = mm/th) for side milling (A). | |||||||||||

| A | Cutting Speed

|

D1

|

|||||||||||

| Material

|

ap | ae | min | max | mm | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | ||

| P | 0 | 3 x D | 0.1 x D | 150 | – | 440 | fz | 0,072 | 0,086 | 0,099 | 0,121 | 0,137 | 0,149 |

| 1 | 3 x D | 0.1 x D | 150 | – | 440 | fz | 0,072 | 0,086 | 0,099 | 0,121 | 0,137 | 0,149 | |

| 2 | 3 x D | 0.1 x D | 140 | – | 418 | fz | 0,072 | 0,086 | 0,099 | 0,121 | 0,137 | 0,149 | |

| 3 | 3 x D | 0.1 x D | 120 | – | 352 | fz | 0,060 | 0,073 | 0,084 | 0,105 | 0,121 | 0,137 | |

| 4 | 3 x D | 0.1 x D | 90 | – | 330 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,106 | 0,117 | |

| 5 | 3 x D | 0.1 x D | 60 | – | 220 | fz | 0,048 | 0,058 | 0,067 | 0,084 | 0,097 | 0,109 | |

| 6 | 3 x D | 0.1 x D | 50 | – | 165 | fz | 0,040 | 0,048 | 0,056 | 0,068 | 0,078 | 0,085 | |

| M | 1 | 3 x D | 0.1 x D | 90 | – | 253 | fz | 0,060 | 0,073 | 0,084 | 0,105 | 0,121 | 0,137 |

| 2 | 3 x D | 0.1 x D | 60 | – | 176 | fz | 0,048 | 0,058 | 0,067 | 0,084 | 0,097 | 0,109 | |

| 3 | 3 x D | 0.1 x D | 60 | – | 154 | fz | 0,040 | 0,048 | 0,056 | 0,068 | 0,078 | 0,085 | |

| K | 1 | 3 x D | 0.1 x D | 120 | – | 330 | fz | 0,072 | 0,086 | 0,099 | 0,121 | 0,137 | 0,149 |

| 2 | 3 x D | 0.1 x D | 110 | – | 308 | fz | 0,060 | 0,073 | 0,084 | 0,105 | 0,121 | 0,137 | |

| 3 | 3 x D | 0.1 x D | 110 | – | 286 | fz | 0,048 | 0,058 | 0,067 | 0,084 | 0,097 | 0,109 | |

| S | 1 | 3 x D | 0.1 x D | 50 | – | 198 | fz | 0,060 | 0,073 | 0,084 | 0,105 | 0,121 | 0,137 |

| 2 | 3 x D | 0.1 x D | 25 | – | 88 | fz | 0,032 | 0,038 | 0,045 | 0,056 | 0,065 | 0,074 | |

| 3 | 3 x D | 0.1 x D | 25 | – | 88 | fz | 0,032 | 0,038 | 0,045 | 0,056 | 0,065 | 0,074 | |

| 4 | 3 x D | 0.1 x D | 50 | – | 132 | fz | 0,044 | 0,053 | 0,062 | 0,077 | 0,089 | 0,100 | |

| H | 1 | 3 x D | 0.1 x D | 80 | – | 308 | fz | 0,054 | 0,065 | 0,075 | 0,092 | 0,106 | 0,117 |

| 2 | 3 x D | 0.1 x D | 70 | – | 264 | fz | 0,040 | 0,048 | 0,056 | 0,068 | 0,078 | 0,085 | |

-

KOR™6DT

-

KOR™ Series End Mills: Solid End Mills for Dynamic Milling