K-Lock™ Profiling

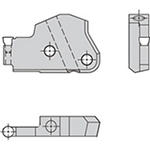

K-Lock™ profiling inserts offer a versatile solution for machining deep grooves and profiles, making them a central tool for your machining applications. The unique insert clamping system ensures chip removal is unobstructed during your operations. K-Lock™ profiling inserts come in both molded and ground peripheries, providing flexibility. Explore the full range of K-Lock™ inserts, toolholders, and modular blades.

- P Steel (70)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(70)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(70)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(70)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(70)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(70)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(70)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(70)

- M Stainless Steel (86)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(86)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(86)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(86)

- K Cast Iron (34)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(34)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(34)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(34)

- N Non-Ferrous Materials (58)

- N1Wrought Aluminum (58)

- N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2%(58)

- N4Copper, Brass, Zinc-based on machinability index range of 70-100 (58)

- N5Nylon, Plastics, Rubbers, Phenolics, Resins, Fiberglass (58)

- N6Carbon, Graphite Composites, CFRP (41)

- N7MMC's (49)

- S High-Temp Alloys (94)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(94)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(94)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(94)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(94)

CRT Profiling (17)

Deep Grooving (17)

Multiple Direction Cutting (51)

- Heavily Interrupted Cut (42)

- Lightly Interrupted Cut (67)

- Smooth Cut (87)

- 60.0 (4)

- 90.0 (48)

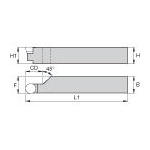

- Toolholder (35)

- 1.0 (87)

- 54.296 mm(3)

- 54.306 mm(2)

- 66.996 mm(6)

- 73.346 mm(3)

- 84.776 mm(2)

- 92.396 mm(1)

- 150.0 mm(3)

- 152.4 mm(23)

- 170.0 mm(1)

- 177.8 mm(8)

- 2.375 mm(25)

- 3.175 mm(34)

- 4.775 mm(28)

- 6.35 mm(16)

- 0.0 mm(68)

- K313 (49)

- KC5010 (59)

- KC5025 (14)

- KC5410 (41)

- KC730 (55)

- KCP25B (34)

- KCP25C (32)

- KCS10 (55)

- KCS10B (55)

- KCU10 (60)

- KCU10B (63)

- KCU25B (14)

- L (13)

- R (22)

- N (87)

- 25.4 mm(1)

- 25.476 mm(2)

- 25.5 mm(3)

- 25.806 mm(2)

- 25.908 mm(2)

- 26.213 mm(2)

- 31.826 mm(2)

- 32.156 mm(2)

- 32.258 mm(2)

- 32.563 mm(2)

- 38.1 mm(1)

- 38.176 mm(2)

- 38.506 mm(2)

- 38.608 mm(2)

- 38.913 mm(2)

- 41.275 mm(1)

- 44.45 mm(2)

- 47.625 mm(2)

- 50.8 mm(1)

- B (21)

- E (7)

- S (7)

- NEUTRAL (ZERO) (34)

- T (52)

- 50 (17)

- 12.7 mm(8)

- 13.919 mm(2)

- 19.05 mm(18)

- 20.0 mm(4)

- 21.387 mm(2)

- 25.4 mm(6)

- 31.75 mm(6)

- 38.1 mm(3)

- 49.53 mm(2)

- 57.15 mm(1)

- R-ROUND (52)

- 4.75 mm(3)

- 4.775 mm(9)

- 6.35 mm(15)

- 9.525 mm(15)

- 12.7 mm(10)

- FS (16)

- HP (14)

- MP (4)

- H W (103)

- G (30)

- M (22)

- SQUARE SHANK (35)

- 25.0 mm(3)

- 25.4 mm(12)

- 31.75 mm(11)

- 32.0 mm(1)

- 38.1 mm(8)

- 25.0 mm(4)

- 25.4 mm(12)

- 31.75 mm(11)

- 38.1 mm(8)