Product Similar To :

CNMA

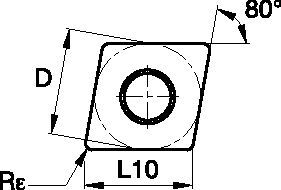

Kenloc™ Inserts

Material Number3751896

ISO Catalog IDCNMA120408ANSI Catalog IDCNMA432

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3751896 |

| ISO Catalog ID | CNMA120408 |

| ANSI Catalog ID | CNMA432 |

| Grade | KCK05 |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [L10] Insert Cutting Edge Length | 12.896 mm |

| [L10] Insert Cutting Edge Length | 0.5077 in |

| [S] Insert Thickness | 4.763 mm |

| [S] Insert Thickness | 0.1875 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| [D1] Insert Hole Size | 5.16 mm |

| [D1] Insert Hole Size | 0.2031 in |

Workpiece Materials

- Cast Iron

Grades

KCK05

Composition: A multilayered coating with moderately thick MTCVD TiCN-Al2O3 layers over a highly deformation-resistant carbide substrate.

Application: Designed for high-speed machining of grey and ductile irons. The substrate and coating architecture together with CW5 post-coat treatment ensure a tremendous tool life advantage, especially when cutting higher tensile strength ductile and grey irons where workpiece size consistency and reliability of tool life are critical. Excellent both in straight and varied depths of cut.

Features and benefits

- Beyond™ Drive™ grades included

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use