Product Similar To :

WPGT-UF

Screw-On Inserts

Material Number4045347

ISO Catalog IDWPGT040202UFANSI Catalog IDWPGT21505UF

- M Stainless Steel

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4045347 |

| ISO Catalog ID | WPGT040202UF |

| ANSI Catalog ID | WPGT21505UF |

| Grade | KCU10 |

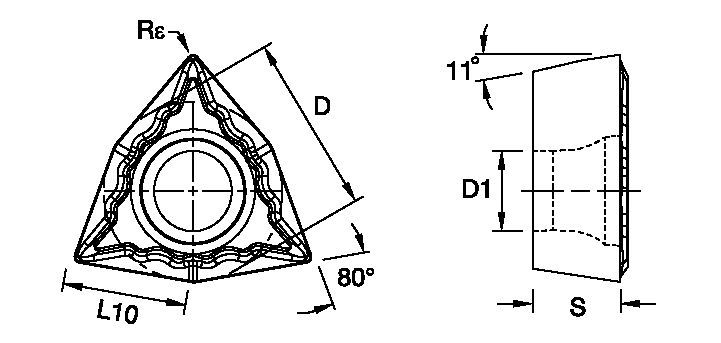

| [D] Insert IC Size | 6.35 mm |

| [D] Insert IC Size | 0.25 in |

| [L10] Insert Cutting Edge Length | 4.344 mm |

| [L10] Insert Cutting Edge Length | 0.171 in |

| [S] Insert Thickness | 2.381 mm |

| [S] Insert Thickness | 0.094 in |

| [Rε] Corner Radius | 0.2 mm |

| [Rε] Corner Radius | 0.008 in |

| [D1] Insert Hole Size | 2.794 mm |

| [D1] Insert Hole Size | 0.11 in |

Workpiece Materials

- Stainless Steel

Grades

KCU10

Composition: An advanced multilayer PVD coating over a very deformation-resistant unalloyed carbide substrate. The new and improved coating improves edge stability with wide range speed and feed capabilities.

Application: The KCU10™ grade is ideal for finishing to general machining of most workpiece materials at a wide range of speed and feed capabilities. Excellent for machining most steels, stainless steels, cast irons, non-ferrous materials, and super alloys with improved edge toughness and higher cutting speed/feed capability.

Features and benefits

- Finishing geometry for multiple material groups.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use