Product Similar To:

Kendex™ • Negative Inserts • DNGX

ISO Turning Insert • Negative D-Style

Material Number6770846

ISO Catalog IDDNGX120712S02530ANSI Catalog IDDNGX120712S02530

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6770846 |

| ISO Catalog ID | DNGX120712S02530 |

| ANSI Catalog ID | DNGX120712S02530 |

| Grade | KYHK15B |

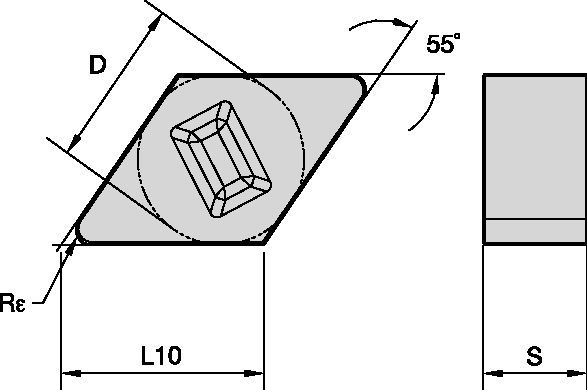

| [D] Insert IC Size | 10 mm |

| [D] Insert IC Size | 0.394 in |

| [L10] Insert Cutting Edge Length | 12.208 mm |

| [L10] Insert Cutting Edge Length | 0.4806 in |

| [S] Insert Thickness | 7.94 mm |

| [S] Insert Thickness | 0.3125 in |

| [Rε] Corner Radius | 1.2 mm |

| [Rε] Corner Radius | 0.047 in |

Workpiece Materials

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Grades

KYHK15B

Composition: A PVD coated mixed aluminum oxide composite ceramic (Al2O3) with embedded fine-grained titanium carbonitride (TiCN).

Application: KYHK15B is suitable for turning hardened steels (45 HRC–60 HRC), finishing of cast irons and high temperature alloys. This advanced ceramic offers maximum edge strength and excellent wear resistance by achieving performance to compete with CBN.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use