Product Similar To:

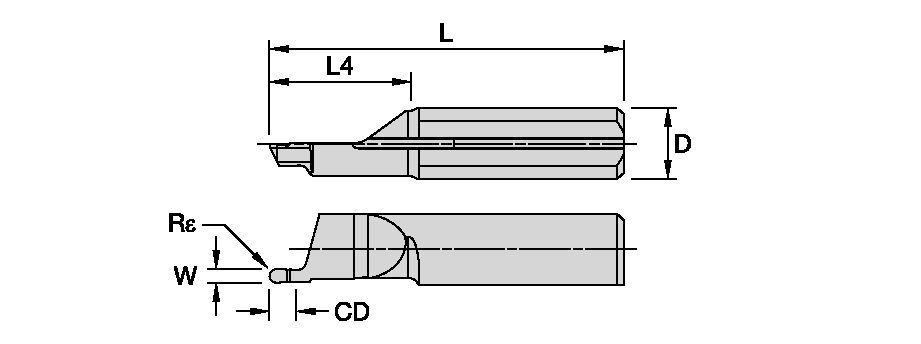

TopSwiss MBS™ Insert • Micro Face Grooving • FI style • Inboard Sweep

Micro Boring • Swiss-Type • Small Parts Machining • Face Grooving • Inboard Sweep

Material Number7221096

ISO Catalog IDR7FI19080C11R099ANSI Catalog IDR7FI19080C11R099

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 7221096 |

| ISO Catalog ID | R7FI19080C11R099 |

| ANSI Catalog ID | R7FI19080C11R099 |

| Grade | KCU25S |

| [DM] Minimum Bore Diameter | 8 mm |

| [DM] Minimum Bore Diameter | 0.315 in |

| [D] Adapter / Shank / Bore Diameter | 7 mm |

| [D] Adapter / Shank / Bore Diameter | 0.2756 in |

| [W] Groove Width | 1.9 mm |

| [W] Groove Width | 0.0748 in |

| [CD] Cutting Depth | 4 mm |

| [CD] Cutting Depth | 0.1575 in |

| [Rε] Corner Radius | 1 mm |

| [Rε] Corner Radius | 0.039 in |

| [L4] Maximum Boring Depth | 11 mm |

| [L4] Maximum Boring Depth | 0.4331 in |

| [L] Overall Length | 26 mm |

| [L] Overall Length | 1.0236 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

Features and benefits

- KCU25S, Universal Coating Designed for Performance and Consistency Across Multiple Materials.

- FI geometry for Face Grooving Inboard Sweep with either Radiused Corners or Full Nose Radius.

- Lengths of Cut from 2xD up to 13xD.

- Extended Depth of Cut Styles with Double Coolant Holes for High Pressure Coolant.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use