Vítejte

Potvrďte své předvolby

Aktualizovat předvolby

Návrhy produktů

Product Family suggestions

Kennametal k vašim službám

Zakaznicke centrum

Vítejte, User Name

Vámi vybraný účet:

Vyskytl se problém s vaším účtem. Kontaktujte prosím zákaznickou podporu.

Účet kupujícího Změnit účet

Účet pro příjemce zásilky Změnit účet

- Ovládací panel

- Spravovat objednávky

- Spravovat kanály

- Adresář

Oznámení

Označit vše jako přečtené- Změnit heslo

- Můj profil

- Odhlásit se

Položka (položky) úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Získejte více za méně s našimi časově omezenými nabídkami! Nakupujte nyní.

Kennametal k vašim službám

Zakaznicke centrum

Položka (položky) úspěšně přidáno do košíku

Zobrazit košík

Zobrazit košík

Úprava řešení

Přidání řešení

Název řešení:{{SolutionName}}- Produkty

- /

- Nástroje pro obrábění kovů

- /

- Frézování

- /

- Frézovací nástroje

- /

- Čelní fréza

- /

- Dodeka Series

- /

- Dodeka™ Mini

- /

- Dodeka™ Mini 45º Cutters

- /

- Inch Cutters

- /

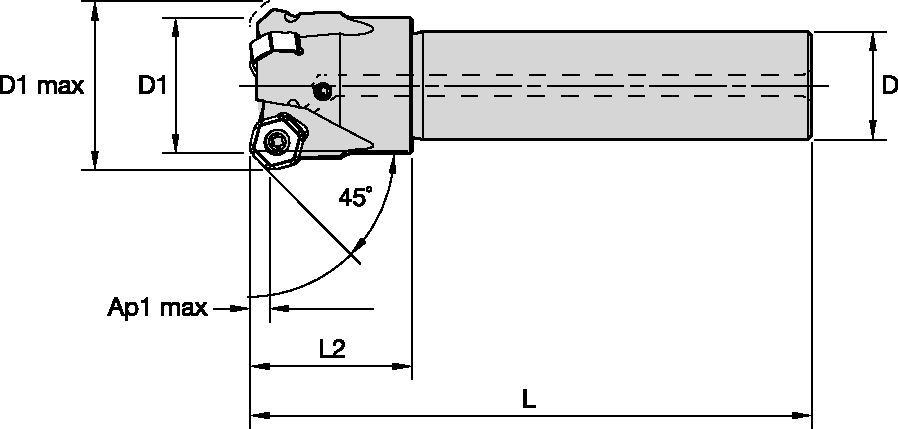

- Dodeka™ Mini 45° • End Mill • Cylindrical Shank • Inch

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

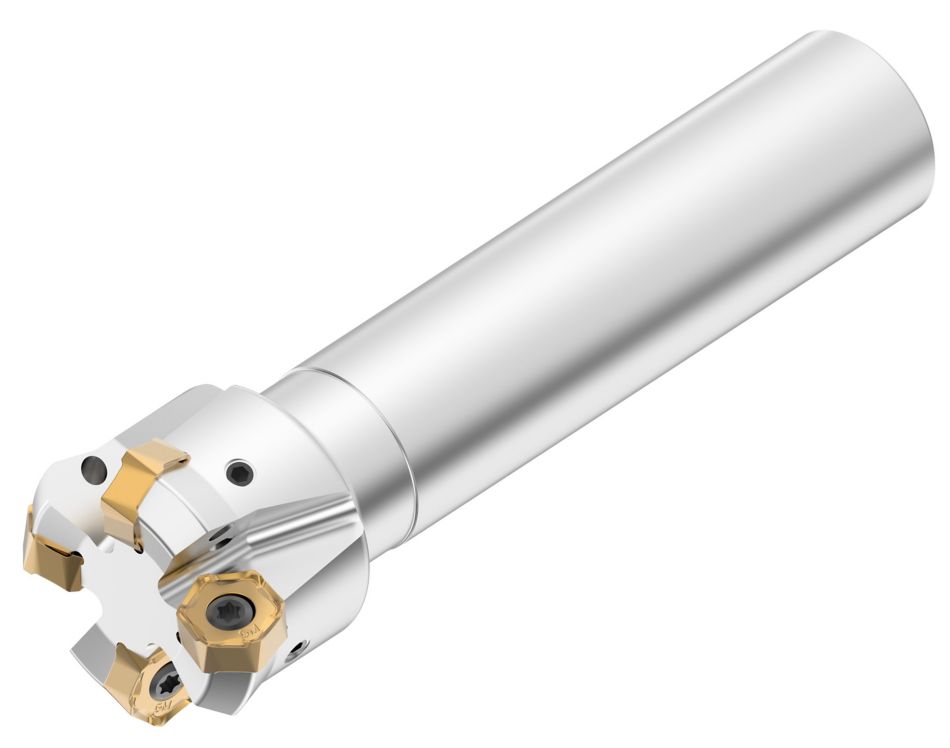

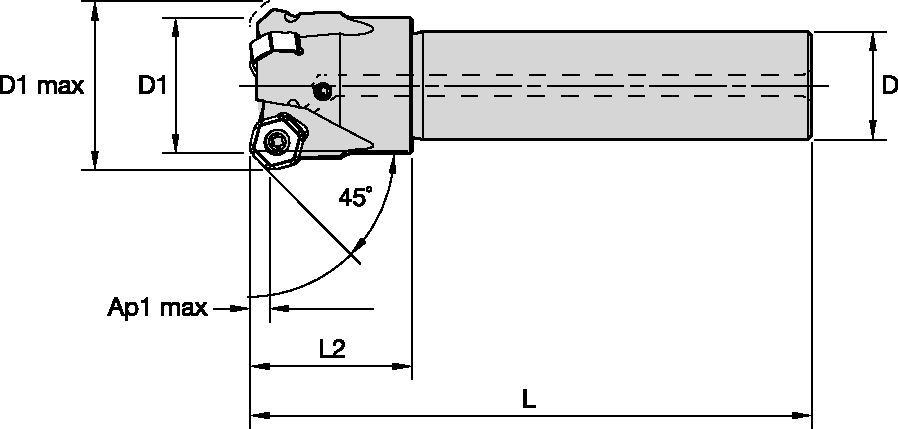

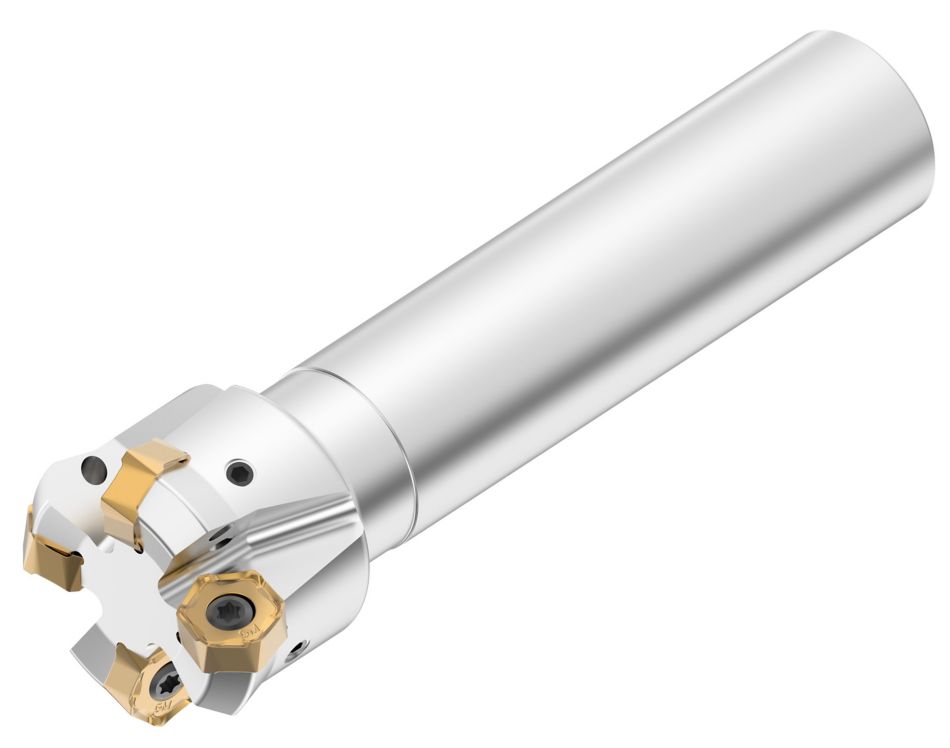

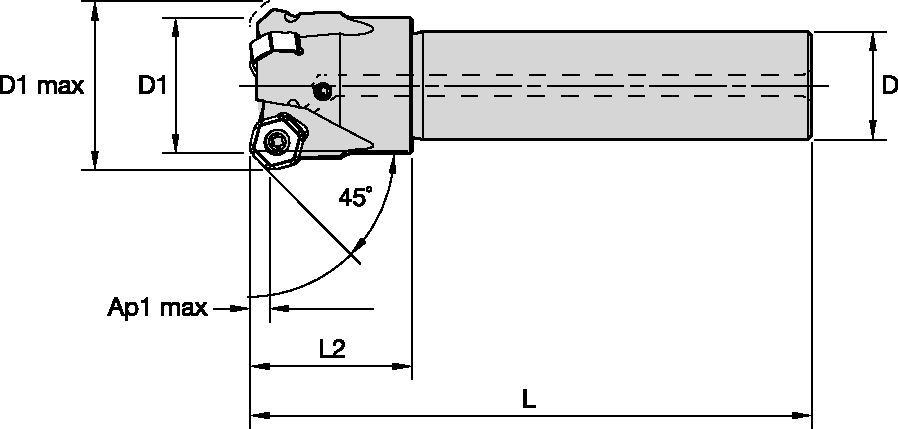

Dodeka™ Mini 45° • End Mill • Cylindrical Shank • Inch

Stopkové frézy

Vlastnosti a výhody

- Internal coolant supply.

Použití

Face Milling

Side Milling/Shoulder Milling: Eased Chamfer

Shank - Cylindrical Plain

Milling - Through Coolant

| Material | Light | Medium | Heavy | |||||||

| P1–P2 | .E..LD | KC522M | .E..LP | KC522M | .E..GP | KC522M | .S..GD | KC522M | .S..HD | KC725M |

| P3–P4 | .E..LD | KCPM40 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPK30 | .S..HD | KCPK30 |

| P5–P6 | .E..LD | KCPM40 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| M1–M2 | .E..LD | KC522M | .E..LM | KC522M | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 |

| K1–K2 | .E..LD | KCK20B | .E..LP | KCK20B | .E..LP | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 |

| K3 | .E..LD | KCKP10 | .E..LP | KCPK30 | .E..LP | KCPK30 | .S..GD | KCK20B | .S..HD | KCPK30 |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| S1–S2 | .E..LD | KC725M | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| H1 | .E..LD | KCKP10 | – | – | .E..GP | KC522M | – | – | – | – |

Doporučené počáteční posuvy [mm]

| Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||

| 30% | 40–100% | |||||

| Insert Geometry | L | M | H | L | M | H |

| .F..LDJ | 0.08 | 0.22 | 0.37 | 0.07 | 0.20 | 0.34 |

| .E..LD | 0.09 | 0.28 | 0.46 | 0.08 | 0.25 | 0.42 |

| .E..LM | 0.08 | 0.23 | 0.38 | 0.07 | 0.21 | 0.35 |

| .E..LP | 0.08 | 0.28 | 0.43 | 0.07 | 0.25 | 0.40 |

| .E..GM | 0.08 | 0.23 | 0.38 | 0.07 | 0.21 | 0.35 |

| .E..GP | 0.08 | 0.28 | 0.44 | 0.07 | 0.25 | 0.40 |

| .S..GD | 0.16 | 0.37 | 0.56 | 0.14 | 0.34 | 0.51 |

| .S..HD | 0.16 | 0.39 | 0.63 | 0.14 | 0.36 | 0.57 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining. | ||||||

Recommended Starting Feeds [IPT]

| Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||

| 30% | 40–100% | |||||

| Insert Geometry | L | M | H | L | M | H |

| .F..LDJ | 0.003 | 0.009 | 0.015 | 0.003 | 0.008 | 0.014 |

| .E..LD | 0.003 | 0.011 | 0.019 | 0.003 | 0.010 | 0.017 |

| .E..LM | 0.003 | 0.009 | 0.015 | 0.003 | 0.009 | 0.014 |

| .E..LP | 0.003 | 0.011 | 0.017 | 0.003 | 0.010 | 0.016 |

| .E..GM | 0.003 | 0.009 | 0.015 | 0.003 | 0.009 | 0.014 |

| .E..GP | 0.003 | 0.011 | 0.017 | 0.003 | 0.010 | 0.016 |

| .S..GD | 0.006 | 0.014 | 0.022 | 0.006 | 0.013 | 0.020 |

| .S..HD | 0.006 | 0.015 | 0.025 | 0.006 | 0.014 | 0.023 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining. | ||||||

Doporučená počáteční rychlost [m/min.]

| Grade | K313 | KC410M | KC522M | KC725M | KCK15 | KCPK30 | KCKP10 | KCK20B | KCPM40 | KCSM30 | KCSM40 | KTPK20 | KY3500 | |||||||||||||||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | – | – | – | – | – | – | 395 | 345 | 325 | 310 | 275 | 260 | – | – | – | 545 | 475 | 445 | 370 | 340 | 310 | – | – | – | 355 | 310 | 295 | 440 | 380 | 350 | 420 | 375 | 345 | 430 | 360 | 300 | – | – | – |

| 2 | – | – | – | – | – | – | 330 | 290 | 240 | 265 | 230 | 190 | – | – | – | 335 | 305 | 275 | 350 | 315 | 280 | – | – | – | 300 | 260 | 215 | 365 | 320 | 260 | 360 | 320 | 255 | 315 | 260 | 240 | – | – | – | |

| 3 | – | – | – | – | – | – | 305 | 260 | 210 | 240 | 205 | 170 | – | – | – | 305 | 275 | 245 | 330 | 280 | 245 | – | – | – | 275 | 235 | 190 | 340 | 285 | 234 | 335 | 275 | 230 | 290 | 240 | 215 | – | – | – | |

| 4 | – | – | – | – | – | – | 270 | 220 | 180 | 215 | 180 | 145 | – | – | – | 270 | 220 | 190 | 280 | 245 | 190 | – | – | – | 245 | 205 | 160 | 300 | 245 | 195 | 285 | 240 | 190 | 250 | 215 | 190 | – | – | – | |

| 5 | – | – | – | – | – | – | 220 | 205 | 180 | 180 | 160 | 145 | – | – | – | 225 | 200 | 180 | 250 | 190 | 150 | – | – | – | 205 | 185 | 160 | 245 | 220 | 190 | 240 | 210 | 180 | 220 | 200 | 180 | – | – | – | |

| 6 | – | – | – | – | – | – | 200 | 150 | 120 | 155 | 120 | 95 | – | – | – | 190 | 160 | 130 | 190 | 150 | 130 | – | – | – | 180 | 140 | 110 | 215 | 165 | 130 | 210 | 155 | 120 | 190 | 155 | 120 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 245 | 215 | 200 | 205 | 180 | 160 | – | – | – | 245 | 220 | 185 | – | – | – | – | – | – | 235 | 205 | 185 | 255 | 210 | 190 | 290 | 230 | 200 | 260 | 210 | 180 | – | – | – |

| 2 | – | – | – | – | – | – | 220 | 190 | 180 | 185 | 155 | 130 | – | – | – | 220 | 190 | 170 | – | – | – | – | – | – | 210 | 180 | 150 | 230 | 190 | 150 | 260 | 205 | 170 | 235 | 200 | 165 | – | – | – | |

| 3 | – | – | – | – | – | – | 170 | 145 | 115 | 140 | 120 | 95 | – | – | – | 175 | 155 | 140 | – | – | – | – | – | – | 155 | 140 | 110 | 170 | 145 | 115 | 190 | 160 | 125 | 175 | 145 | 120 | – | – | – | |

| K | 1 | 190 | 165 | 140 | – | – | – | 275 | 245 | 220 | – | – | – | 505 | 460 | 410 | 355 | 320 | 290 | 490 | 390 | 280 | 430 | 340 | 280 | – | – | – | – | – | – | – | – | – | 275 | 235 | 190 | 965 | 875 | 780 |

| 2 | – | – | – | – | – | – | 215 | 190 | 180 | – | – | – | 400 | 355 | 330 | 280 | 250 | 230 | 335 | 290 | 225 | 330 | 270 | 220 | – | – | – | – | – | – | – | – | – | 220 | 180 | 155 | 760 | 685 | 635 | |

| 3 | – | – | – | – | – | – | 180 | 160 | 145 | – | – | – | 335 | 300 | 275 | 235 | 210 | 190 | 280 | 230 | 190 | 250 | 210 | 165 | – | – | – | – | – | – | – | – | – | 180 | 155 | 125 | – | – | – | |

| N | 1 | 875 | 765 | 660 | 1335 | 1185 | 1090 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 1185 | 1090 | 950 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 1185 | 1090 | 950 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 45 | 40 | 35 | 50 | 45 | 35 | 60 | 45 | 30 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 40 | 35 | 25 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 45 | 40 | 35 | 50 | 45 | 35 | 65 | 45 | 30 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 50 | 40 | 25 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 45 | 35 | 65 | 50 | 35 | 75 | 50 | 35 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 50 | 45 | 35 | 50 | 45 | 35 | – | – | – | 60 | 50 | 40 | – | – | – | – | – | – | 65 | 60 | 40 | 70 | 65 | 45 | 90 | 70 | 45 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | 145 | 110 | 85 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 120 | 90 | – | – | – | – | – | – | – | – | – |

| Recommended starting speeds are in bold type. As the average chip thickness increases, speed should be decreased. Material groups P, M, K, and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||||||||

| Grade | K313 | KC410M | KC522M | KC725M | KCK15 | KCPK30 | KCKP10 | KCK20B | KCPM40 | KCSM30 | KCSM40 | KTPK20 | KY3500 | |||||||||||||||||||||||||||

| Chip Thickness hex Inch | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | ||||||||||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | – | – | – | – | – | – | 1295 | 1115 | 1065 | 1015 | 900 | 855 | – | – | – | 1790 | 1560 | 1460 | 1215 | 1115 | 1015 | – | – | – | 1165 | 1015 | 970 | 1445 | 1245 | 1150 | 1380 | 1230 | 1130 | 1410 | 1180 | 985 | – | – | – |

| 2 | – | – | – | – | – | – | 1085 | 950 | 785 | 870 | 755 | 625 | – | – | – | 1100 | 1000 | 900 | 1150 | 1035 | 920 | – | – | – | 985 | 855 | 705 | 1200 | 1050 | 855 | 1180 | 1050 | 835 | 1035 | 855 | 785 | – | – | – | |

| 3 | – | – | – | – | – | – | 1000 | 855 | 690 | 785 | 675 | 560 | – | – | – | 1000 | 900 | 805 | 1085 | 920 | 805 | – | – | – | 900 | 770 | 625 | 1115 | 935 | 770 | 1100 | 900 | 755 | 950 | 785 | 705 | – | – | – | |

| 4 | – | – | – | – | – | – | 885 | 720 | 590 | 705 | 590 | 475 | – | – | – | 885 | 720 | 625 | 920 | 805 | 625 | – | – | – | 805 | 675 | 525 | 985 | 805 | 640 | 935 | 785 | 625 | 820 | 705 | 625 | – | – | – | |

| 5 | – | – | – | – | – | – | 720 | 675 | 590 | 590 | 525 | 475 | – | – | – | 740 | 655 | 590 | 820 | 625 | 490 | – | – | – | 675 | 605 | 525 | 805 | 720 | 625 | 785 | 690 | 590 | 720 | 655 | 590 | – | – | – | |

| 6 | – | – | – | – | – | – | 655 | 490 | 395 | 510 | 395 | 310 | – | – | – | 625 | 525 | 425 | 625 | 490 | 425 | – | – | – | 590 | 460 | 360 | 705 | 540 | 425 | 690 | 510 | 395 | 625 | 510 | 395 | – | – | – | |

| M | 1 | – | – | – | – | – | – | 805 | 705 | 655 | 675 | 590 | 525 | – | – | – | 805 | 720 | 605 | – | – | – | – | – | – | 770 | 675 | 605 | 835 | 690 | 625 | 950 | 755 | 655 | 855 | 690 | 590 | – | – | – |

| 2 | – | – | – | – | – | – | 720 | 625 | 590 | 605 | 510 | 425 | – | – | – | 720 | 625 | 560 | – | – | – | – | – | – | 690 | 590 | 490 | 755 | 625 | 490 | 855 | 675 | 560 | 770 | 655 | 540 | – | – | – | |

| 3 | – | – | – | – | – | – | 590 | 525 | 475 | 460 | 395 | 310 | – | – | – | 575 | 510 | 460 | – | – | – | – | – | – | 510 | 460 | 360 | 560 | 475 | 375 | 625 | 525 | 410 | 575 | 475 | 395 | – | – | – | |

| K | 1 | 625 | 540 | 460 | – | – | – | 900 | 805 | 720 | – | – | – | 1655 | 1510 | 1345 | 1165 | 1050 | 950 | 1610 | 1280 | 920 | 1410 | 1115 | 920 | – | – | – | – | – | – | – | – | – | 900 | 770 | 625 | 3165 | 2870 | 2560 |

| 2 | – | – | – | – | – | – | 705 | 625 | 590 | – | – | – | 1310 | 1165 | 1085 | 920 | 820 | 755 | 1100 | 950 | 740 | 1085 | 885 | 720 | – | – | – | – | – | – | – | – | – | 720 | 590 | 510 | 2495 | 2245 | 2085 | |

| 3 | – | – | – | – | – | – | 590 | 525 | 475 | – | – | – | 1100 | 985 | 900 | 700 | 690 | 625 | 920 | 755 | 625 | 820 | 690 | 540 | – | – | – | – | – | – | – | – | – | 590 | 510 | 410 | – | – | – | |

| N | 1 | 2870 | 2510 | 2165 | 4380 | 3890 | 3575 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | 3890 | 3575 | 3115 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | 3890 | 3575 | 3115 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 150 | 130 | 115 | 165 | 150 | 115 | 195 | 150 | 100 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 130 | 115 | 80 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 150 | 130 | 115 | 165 | 150 | 115 | 215 | 150 | 100 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 165 | 130 | 80 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | – | – | – | 195 | 150 | 115 | 215 | 165 | 115 | 245 | 165 | 115 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 165 | 150 | 115 | 165 | 150 | 115 | – | – | – | 195 | 165 | 130 | – | – | – | – | – | – | 215 | 195 | 130 | 230 | 215 | 150 | 295 | 230 | 150 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | 475 | 360 | 280 | – | – | – | – | – | – | – | – | – | 525 | 395 | 310 | – | – | – | – | – | – | 525 | 395 | 295 | – | – | – | – | – | – | – | – | – |

| Recommended starting speeds are in bold type. As the average chip thickness increases, speed should be decreased. Material groups P, M, K, and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||||||||||||||||||||||||||||||||