Product Similar To:

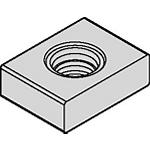

Inserts for 0° LN Slotting Cutters • LNEQ

Indexable Inserts • 0° LN LNEU/LNEQ

Material Number100000281

Features and benefits

- Very strong geometry for roughing application.

- Four cutting edges.

| LN Slotting Series • Insert Selection Guide | ||||||

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1-P2 | LNEU… | KCPM40 | LNEU…SGP | KCPM40 | LNEQ... | KC725M |

| P3-P4 | LNEU… | KCPK30 | LNEU…SGP | KCPM40 | LNEQ... | KC725M |

| P5-P6 | LNEU… | KC725M | LNEU…SGP | KC725M | LNEQ... | KC725M |

| M1-M2 | LNEU… | KC725M | LNEU…SGP | KC725M | LNEQ... | KC725M |

| M3 | LNEU… | KCPM40 | LNEU…SGP | KCPM40 | LNEQ... | KC725M |

| K1-K2 | LNEU… | KCK20B | LNEU… | KCK20B | LNEQ... | KCK15 |

| K3 | LNEU… | KCK20B | LNEQ... | KCK20B | LNEQ... | KCK20B |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | LNEU… | KC725M | LNEU…SGP | KC725M | LNEQ... | KC725M |

| S3 | LNEU… | KCPK30 | LNEU…SGP | KCPM40 | LNEQ... | KC725M |

| S4 | LNEU… | KC725M | LNEU…SGP | KC725M | LNEQ... | KC725M |

| H1 | – | – | – | – | – | – |

| LN Slotting Series • Recommended Starting Feeds [mm/th] | |||||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| LNEU… | 0.17 | 0.47 | 0.7 | 0.12 | 0.34 | 0.5 | 0.09 | 0.26 | 0.38 | 0.08 | 0.22 | 0.33 | 0.07 | 0.2 | 0.3 |

| LNEU…SGP | 0.23 | 0.52 | 0.81 | 0.17 | 0.37 | 0.58 | 0.13 | 0.28 | 0.43 | 0.11 | 0.24 | 0.38 | 0.1 | 0.22 | 0.35 |

| LNEQ... | 0.23 | 0.59 | 0.95 | 0.17 | 0.43 | 0.68 | 0.13 | 0.32 | 0.51 | 0.11 | 0.28 | 0.44 | 0.1 | 0.25 | 0.41 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||

| LN Slotting Series • Recommended Starting Speed [m/min] | |||||||||||||||||||

| Grade | KC520M | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | |||||||||||||

| Chip Thickness hex mm | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||||||

| Material Group | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | Max | Start | Min | |

| P | 1 | – | – | – | 260 | 230 | 215 | – | – | – | 455 | 395 | 370 | – | – | – | 295 | 260 | 245 |

| 2 | – | – | – | 220 | 190 | 160 | – | – | – | 280 | 255 | 230 | – | – | – | 250 | 215 | 180 | |

| 3 | – | – | – | 200 | 170 | 140 | – | – | – | 255 | 230 | 205 | – | – | – | 230 | 195 | 160 | |

| 4 | – | – | – | 180 | 150 | 120 | – | – | – | 225 | 185 | 160 | – | – | – | 205 | 170 | 135 | |

| 5 | – | – | – | 150 | 135 | 120 | – | – | – | 190 | 170 | 150 | – | – | – | 170 | 155 | 135 | |

| 6 | – | – | – | 130 | 100 | 80 | – | – | – | 160 | 135 | 110 | – | – | – | 150 | 115 | 90 | |

| M | 1 | – | – | – | 170 | 150 | 135 | – | – | – | 205 | 185 | 155 | – | – | – | 195 | 170 | 155 |

| 2 | – | – | – | 155 | 130 | 110 | – | – | – | 185 | 160 | 140 | – | – | – | 175 | 150 | 125 | |

| 3 | – | – | – | 115 | 100 | 80 | – | – | – | 145 | 130 | 115 | – | – | – | 130 | 115 | 90 | |

| K | 1 | 270 | 245 | 215 | – | – | – | 420 | 385 | 340 | 295 | 265 | 240 | 360 | 290 | 245 | – | – | – |

| 2 | 210 | 190 | 175 | – | – | – | 335 | 295 | 275 | 235 | 210 | 190 | 280 | 230 | 195 | – | – | – | |

| 3 | 175 | 160 | 145 | – | – | – | 280 | 250 | 230 | 195 | 175 | 160 | 210 | 175 | 140 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 |

| 2 | – | – | – | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | |

| 3 | – | – | – | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | |

| 4 | – | – | – | 50 | 45 | 30 | – | – | – | 50 | 45 | 35 | – | – | – | 55 | 50 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||