Product Similar To:

Inserts for Fix-Perfect™ 90° • SPHX1205-W • Finishing • GP

Indexable Inserts • SPHX1205... • Roughing • Finishing

Material Number100001166

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| (Light geometry) | – | (Strong geometry) | ||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| K3 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| (Light geometry) | – | (Strong geometry) | ||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KC520M | .E..GP | KCK15 | .E..GP | KCK15 |

| K3 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Recommended Starting Feeds [mm]

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GPB | 0,12 | 0,46 | 0,82 | 0,08 | 0,33 | 0,59 | 0,06 | 0,25 | 0,44 | 0,06 | 0,22 | 0,38 | 0,05 | 0,20 | 0,35 | .E..GPB |

| .T..GPB | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 | .T..GPB |

| .S..GPB | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 | .S..GPB |

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | 0,12 | 0,46 | 0,82 | 0,08 | 0,33 | 0,59 | 0,06 | 0,25 | 0,44 | 0,06 | 0,22 | 0,38 | 0,05 | 0,20 | 0,35 | .E..GP |

| .S..GP | 0,23 | 0,59 | 0,95 | 0,17 | 0,43 | 0,68 | 0,13 | 0,32 | 0,51 | 0,11 | 0,28 | 0,44 | 0,10 | 0,25 | 0,41 | .S..GP |

| Light | General | Heavy |

Recommended Starting Speeds [m/min]

| Material Group | KB1340 | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 1370 | 915 | 490 | 270 | 245 | 215 | 420 | 385 | 340 | 230 | 195 | 160 | 295 | 265 | 240 | 805 | 730 | 650 |

| 2 | – | – | – | 210 | 190 | 175 | 335 | 295 | 275 | 185 | 150 | 130 | 235 | 210 | 190 | 635 | 570 | 530 | |

| 3 | – | – | – | 175 | 160 | 145 | 280 | 250 | 230 | 150 | 130 | 105 | 195 | 175 | 160 | 535 | 475 | 435 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [m/min]

| Material Group | KB1340 | KC520M | KCK15 | KCPK30 | KY3500 | |||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 1370 | 915 | 490 | 270 | 245 | 215 | 420 | 385 | 340 | 295 | 265 | 240 | 805 | 730 | 650 |

| 2 | – | – | – | 210 | 190 | 175 | 335 | 295 | 275 | 235 | 210 | 190 | 635 | 570 | 530 | |

| 3 | – | – | – | 175 | 160 | 145 | 280 | 250 | 230 | 195 | 175 | 160 | 535 | 475 | 435 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

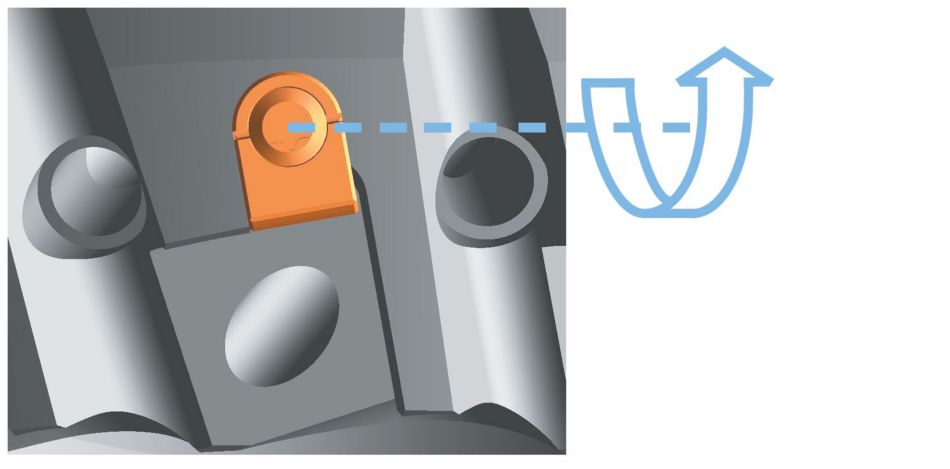

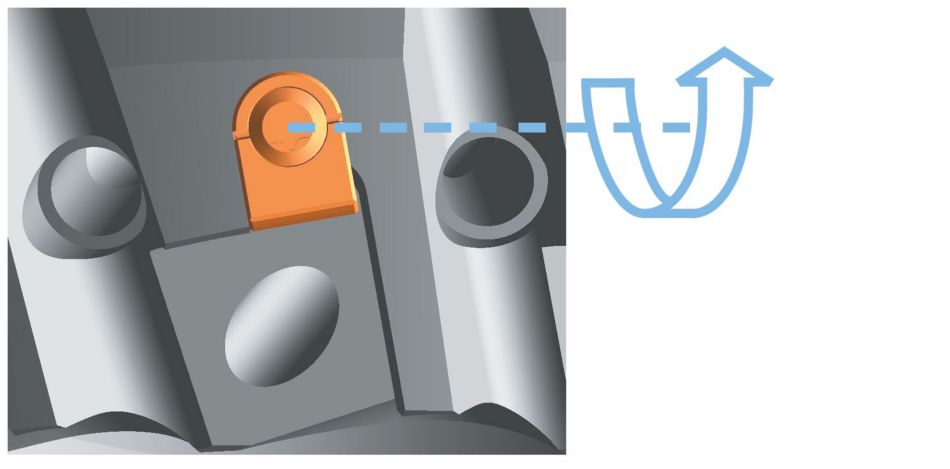

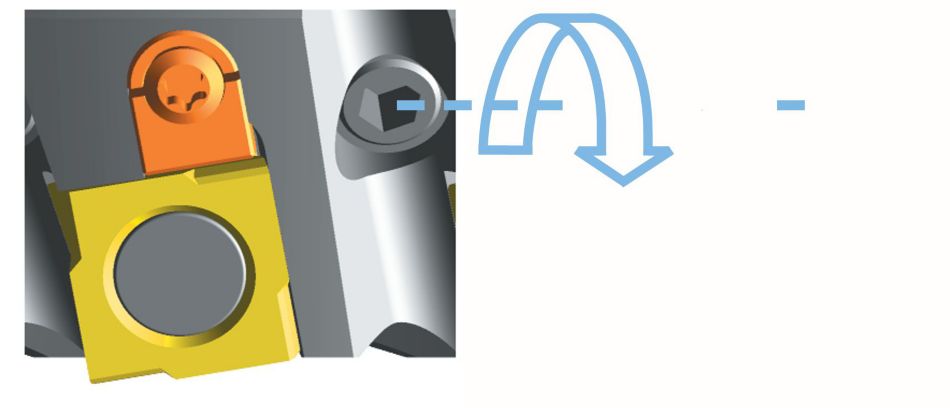

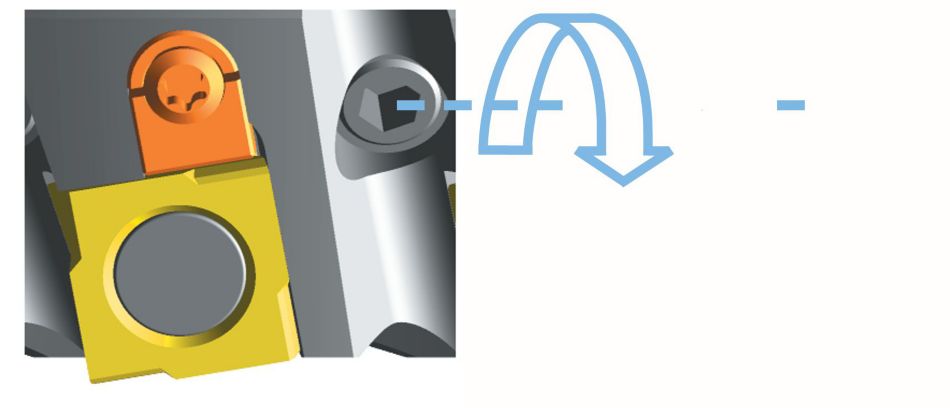

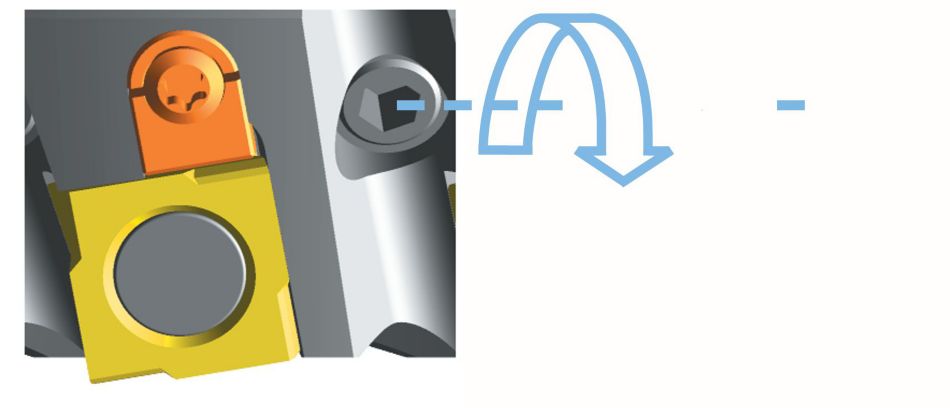

Insert Assembly for Fix-Perfect™ Cast Iron Milling Cutters

| roughing | procedures | roughing/finishing | |||

|  |  |  | ||

| insert seat | insert seat | ||||

| standard | adjustable | standard | adjustable | ||

| ― |  | 1 | Reset adjusting element T x T9 | ― |  |

|  | 2 | insert roughing insert tighten SW 3 MAn = 5 Nm |  | ― |

| ― |  | 3 | tighten adjusting element gently | ― | ― |

| 4 | insert finishing insert and pre-tighten SW 3 M VG = 1 Nm | ― |  | ||

| 5 | the finishing insert is positioned 0,04mm in front of the highest roughing insert | ― | 0,04mm (.0016in.) | ||

| 6 | tighten the finishing insert MAn = 5 Nm | ― |  | ||