Product Similar To :

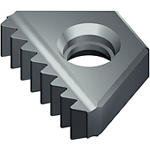

Inserts for TMS • Thread Milling • Internal • ISO Thread • Coarse

Indexable Inserts • Thread Profiles

Material Number100000349

Features and benefits

- ISO metric screw thread style.

STN Series

| Materials | Brinell | surface speeds | indexable inserts | |

| steel | HB | KC610M | KC635M | feed fz (IPT) |

| P1 | 125 | 325–675 | 290–590 | .002–.008 |

| P2 | 180 | 290–550 | 290–520 | .002–.008 |

| P3 | 225 | 200–425 | 225–375 | .002–.008 |

| P4 | 250 | 250–490 | 250–500 | .002–.008 |

| P5 | 275 | 250–425 | 250–500 | .002–.006 |

| P6 | 325 | 225–350 | 200–325 | .002–.004 |

| stainless steel | ||||

| M1 | 180 | 325–550 | 375–590 | .002–.004 |

| M2 | 250 | 225–450 | 325–450 | .002–.004 |

| M3 | 330 | 225–375 | 325–375 | .002–.004 |

| cast iron | ||||

| K1 | 180 | 200–425 | 325–450 | .001–.003 |

| K2 | 220 | 200–390 | 250–325 | .002–.006 |

| K3 | 260 | 160–290 | 200–275 | .002–.004 |

| non-ferrous | ||||

| N1 | 60–100 | 325–820 | – | .002–.010 |

| high-temp alloys | ||||

| S1 | 200 | 65–140 | 65–130 | .002–.004 |

| S2 | 250 | 65–90 | 65–90 | .001–.002 |

| S3 | 280 | 50–65 | 50–65 | .001–.002 |

| S4 | 350 | 30–50 | 30–50 | .001–.002 |

| hardened steel | ||||

| H1 | 55HRc | 65–140 | 65–140 | .0004–.001 |