Product Similar To:

TM41 Parallel Cutter Metric • Weldon Shank

TM41 • Weldon® Shank • Parallel Threads

Material Number100030576

Features and benefits

- 21–58mm cutting diameter range.

- For internal and external threading on most types of workpiece materials.

- One tool is used for both right- and left-hand threads.

- All cutters have through-coolant capability.

- Utilizes inserts with various profiles and pitches.

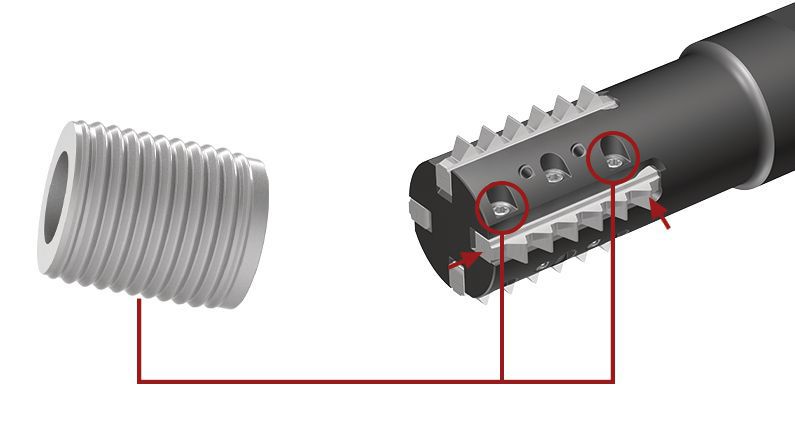

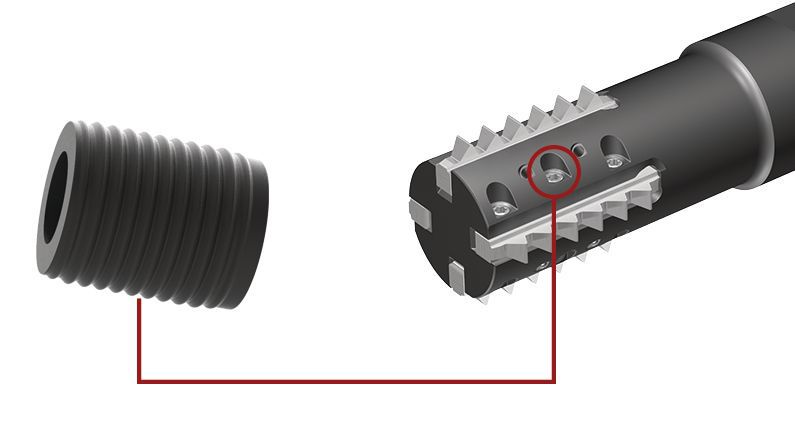

| 2 Step Clamping System |

| Step 1. Location Screw (2) |

|

| Step 2. Clamping Screw |

|

| Thread Application per Toolholder | ||||||||

| min thread Ø | ||||||||

| toolholder | D1 mm | ISO (coarse) | ISO (fine) | UNC | UN/UNF/UNEF/UNS | BSW/BSF | NPT | NPTF |

| TM41D21L45Z1 | 21,20 | M30 x 3.5; M36 x 4 | M28 x 3; M45 x 4 | 1 1/8–7; 1 3/8–6 | 1 1/8–8UN; 1 7/16–6UN | 1 3/8–8BSF; 1 1/4–7BSW | – | – |

| TM41D25L43Z2 | 24,50 | M30 x 3.5; M36 x 4 | M28 x 3; M45 x 4 | 1 1/8–7; 1 3/8–6 | 1 1/8–8UN; 1 7/16–6UN | 1 3/8–8BSF; 1 1/4–7BSW | – | – |

| TM41D30L43Z3 | 30,00 | M36 x 4; M42 x 4.5 | M34 x 3; M34 x 3.5; | 1 3/8–6 | 1 3/8–8UN; 1 7/16–6UN | 1 3/8–8BSF; 1 3/4–7BSF; | – | – |

| TM41D30L65Z3 | 30,00 | M36 x 4; M42 x 4.5 | M34 x 3; M34 x 3.5; | 1 3/8–6 | 1 3/8–8UN; 1 7/16–6UN | 1 3/8–8BSF; 1 3/4–7BSF; | – | – |

| TM41D36L43Z5 | 36,00 | M42 x 4.5; M48 x 5; | M40 x 3; M40 x 3.5; | 1 3/4–5; 2–4.5; | 1 5/8–8UN; 1 5/8–6UN | 1 5/8–8BSF; 1 3/4–7BSF; | 2 1/2–8 | 2 1/2–8 |

| TM41D36L65Z4 | 36,00 | M42 x 4.5; M48 x 5; | M40 x 3; M40 x 3.5; | 1 3/4–5; 2–4.5; | 1 5/8–8UN; 1 5/8–6UN | 1 5/8–8BSF; 1 3/4–7BSF; | 2 1/2–8 | 2 1/2–8 |