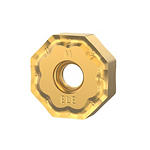

Mill 16

Experience consistent and repeatable performance with Mill 16™, a cutting-edge face milling solution from Kennametal. Whether you're tackling light machining or heavy-duty applications, Mill 16™ shell mills, inserts, and flanges deliver optimal results for general-purpose machining. Specifically crafted for cast iron and compacted graphite iron (CGI) machining, the high-precision periphery ground inserts have sixteen cutting edges, ensuring the lowest cost per edge and exceptional durability. The numbered cutting edges enhance ease of use and tracking. Mill 16™ milling cutters are ideal for roughing tasks on engine heads, blocks, housings, gearboxes, manifolds, and more. The Mill 16 insert features a pocket numbering system for quick set-up times. Elevate your productivity and reduce cycle time with Kennametal's Mill 16™ inserts and shell mills.

- P Steel (62)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(62)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(62)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(62)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(62)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(62)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(62)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(62)

- M Stainless Steel (62)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(62)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(62)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(62)

- K Cast Iron (77)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(77)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(77)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(77)

- S High-Temp Alloys (62)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(62)

Chamfer Milling (50)

Face Milling (58)

- 1.969 in(1)

- 1.97 in(1)

- 2.0 in(2)

- 2.48 in(3)

- 2.5 in(1)

- 3.0 in(3)

- 3.15 in(4)

- 3.937 in(4)

- 4.0 in(3)

- 4.921 in(4)

- 5.0 in(3)

- 6.0 in(3)

- 6.299 in(2)

- 6.3 in(2)

- 7.874 in(4)

- 8.0 in(3)

- 9.84 in(1)

- 9.843 in(3)

- 10.0 in(3)

- 12.0 in(1)

- 12.402 in(1)

- 13.976 in(1)

- 14.0 in(1)

- 15.748 in(1)

- 16.0 in(1)

- 19.685 in(1)

- 20.0 in(1)

- 50.0 mm(2)

- 50.8 mm(2)

- 63.0 mm(3)

- 63.5 mm(1)

- 76.2 mm(3)

- 80.0 mm(4)

- 100.0 mm(4)

- 101.6 mm(3)

- 125.0 mm(4)

- 127.0 mm(3)

- 152.4 mm(2)

- 152.41 mm(1)

- 160.0 mm(2)

- 160.01 mm(2)

- 200.0 mm(2)

- 200.01 mm(2)

- 203.2 mm(2)

- 203.21 mm(1)

- 250.0 mm(2)

- 250.01 mm(2)

- 254.0 mm(2)

- 254.01 mm(1)

- 304.8 mm(1)

- 315.0 mm(1)

- 355.0 mm(1)

- 355.6 mm(1)

- 400.0 mm(1)

- 406.4 mm(1)

- 500.0 mm(1)

- 508.0 mm(1)

- 62.57 mm(1)

- 62.65 mm(1)

- 63.37 mm(1)

- 63.44 mm(1)

- 75.02 mm(2)

- 75.52 mm(1)

- 75.56 mm(1)

- 88.22 mm(1)

- 88.76 mm(2)

- 92.02 mm(2)

- 92.56 mm(2)

- 112.02 mm(2)

- 112.56 mm(2)

- 113.62 mm(1)

- 114.16 mm(2)

- 137.02 mm(2)

- 137.55 mm(2)

- 139.02 mm(1)

- 139.55 mm(2)

- 164.4 mm(1)

- 164.95 mm(2)

- 172.0 mm(2)

- 172.55 mm(2)

- 212.0 mm(2)

- 212.55 mm(2)

- 215.2 mm(1)

- 215.75 mm(2)

- 262.0 mm(2)

- 262.55 mm(2)

- 266.0 mm(1)

- 266.55 mm(2)

- 317.35 mm(1)

- 327.55 mm(1)

- 367.55 mm(1)

- 368.15 mm(1)

- 412.55 mm(1)

- 418.95 mm(1)

- 512.55 mm(1)

- 520.54 mm(1)

- 2.463 in(1)

- 2.466 in(1)

- 2.495 in(1)

- 2.498 in(1)

- 2.953 in(2)

- 2.973 in(1)

- 2.975 in(1)

- 3.473 in(1)

- 3.495 in(2)

- 3.623 in(2)

- 3.644 in(2)

- 4.41 in(2)

- 4.431 in(2)

- 4.473 in(1)

- 4.494 in(2)

- 5.394 in(2)

- 5.416 in(2)

- 5.473 in(1)

- 5.494 in(2)

- 6.472 in(1)

- 6.494 in(2)

- 6.772 in(2)

- 6.793 in(2)

- 8.346 in(2)

- 8.368 in(2)

- 8.472 in(1)

- 8.494 in(2)

- 10.315 in(2)

- 10.337 in(2)

- 10.472 in(1)

- 10.494 in(2)

- 12.494 in(1)

- 12.896 in(1)

- 14.47 in(1)

- 14.494 in(1)

- 16.242 in(1)

- 16.494 in(1)

- 20.179 in(1)

- 20.494 in(1)

- 5.5 mm(58)

- 0.215 in(35)

- 0.216 in(2)

- 0.22 in(21)

- 1.576 in(4)

- 1.58 in(1)

- 1.75 in(2)

- 1.751 in(1)

- 1.772 in(8)

- 1.969 in(6)

- 1.97 in(4)

- 2.0 in(3)

- 2.001 in(1)

- 2.375 in(2)

- 2.376 in(1)

- 2.381 in(2)

- 2.382 in(1)

- 2.4 in(4)

- 2.401 in(2)

- 2.477 in(1)

- 2.48 in(5)

- 2.481 in(10)

- 40.0 mm(1)

- 40.03 mm(4)

- 44.45 mm(2)

- 44.48 mm(1)

- 45.0 mm(8)

- 50.0 mm(6)

- 50.03 mm(4)

- 50.8 mm(3)

- 50.83 mm(1)

- 60.32 mm(2)

- 60.35 mm(1)

- 60.47 mm(2)

- 60.5 mm(1)

- 60.97 mm(4)

- 61.0 mm(2)

- 62.9 mm(1)

- 63.0 mm(5)

- 63.01 mm(2)

- 63.03 mm(8)

- 43.5 (58)

- A-Socket Head Cap Screw (23)

- B-Cutter Retention Screw (5)

- C-Bolt Circle (14)

- KL Screw (4)

- Mill Split Ring Cutter (8)

- SHCS or RetScrw Or BoltCircle (4)

- 10 (9)

- 12 (3)

- 14 (5)

- 16 (3)

- 18 (2)

- 20 (2)

- 22 (2)

- 24 (2)

- 28 (2)

- 34 (2)

- 4 (4)

- 42 (1)

- 44 (1)

- 48 (2)

- 5 (5)

- 56 (2)

- 6 (3)

- 7 (1)

- 70 (2)

- 8 (5)

- 16.0 (77)

- 1.576 in(4)

- 1.58 in(1)

- 1.75 in(2)

- 1.751 in(1)

- 1.772 in(8)

- 1.969 in(6)

- 1.97 in(4)

- 2.0 in(3)

- 2.001 in(1)

- 2.375 in(2)

- 2.376 in(1)

- 2.381 in(2)

- 2.382 in(1)

- 2.4 in(4)

- 2.401 in(2)

- 2.477 in(1)

- 2.48 in(5)

- 2.481 in(10)

- 40.0 mm(1)

- 40.03 mm(4)

- 44.45 mm(2)

- 44.48 mm(1)

- 45.0 mm(8)

- 50.0 mm(6)

- 50.03 mm(4)

- 50.8 mm(3)

- 50.83 mm(1)

- 60.32 mm(2)

- 60.35 mm(1)

- 60.47 mm(2)

- 60.5 mm(1)

- 60.97 mm(4)

- 61.0 mm(2)

- 62.9 mm(1)

- 63.0 mm(5)

- 63.01 mm(2)

- 63.03 mm(8)

- 0.031 in(66)

- 0.079 in(68)

- 0.118 in(59)

- 0.8 mm(66)

- 2.0 mm(68)

- 3.0 mm(59)

- 0.0 mm(77)

- 0.0 in(77)

- KCK15 (64)

- KCK20B (66)

- KCPK30 (62)

- KY3500 (36)

- R (58)

- N (15)

- Y (4)

- FLK - Flange Adapter Kenna (4)

- O-OCTOGON 135 (77)

- FLK35 Mill Split Ring Cutter (4)

- 1.3390 in(1)

- 1.3780 in(3)

- 34.0000 mm(1)

- 35.0000 mm(3)

- O-OCTOGON 135 (19)

- 20.0 mm(19)

- 0.787 in(19)

- 8.21 mm(1)

- 8.28 mm(4)

- 8.284 mm(14)

- 0.323 in(1)

- 0.326 in(4)

- 0.3262 in(14)

- GP (7)

- HB (8)

- LE (3)

- C N (1)

- H W (18)

- E (1)

- G (12)

- P (6)

- SHELL MILL (58)

- 19.05 mm(1)

- 19.1 mm(2)

- 22.0 mm(5)

- 25.4 mm(3)

- 27.0 mm(4)

- 31.76 mm(2)

- 31.8 mm(1)

- 32.0 mm(4)

- 38.1 mm(1)

- 38.12 mm(2)

- 40.0 mm(8)

- 50.8 mm(1)

- 50.82 mm(2)

- 60.0 mm(8)

- 63.5 mm(3)

- 63.51 mm(3)

- 195.0 mm(2)

- 230.0 mm(2)

- 280.0 mm(2)

- 315.0 mm(1)

- 355.0 mm(1)

- 380.0 mm(2)

- 400.0 mm(1)

- 500.0 mm(1)

- 0.75 in(3)

- 0.867 in(2)

- 0.87 in(3)

- 1.0 in(3)

- 1.06 in(2)

- 1.063 in(1)

- 1.064 in(1)

- 1.25 in(3)

- 1.26 in(4)

- 1.5 in(3)

- 1.575 in(4)

- 1.58 in(4)

- 2.0 in(3)

- 2.36 in(4)

- 2.363 in(4)

- 2.5 in(6)

- 7.677 in(2)

- 9.055 in(2)

- 11.024 in(2)

- 12.402 in(1)

- 13.976 in(1)

- 14.961 in(2)

- 15.748 in(1)

- 19.685 in(1)