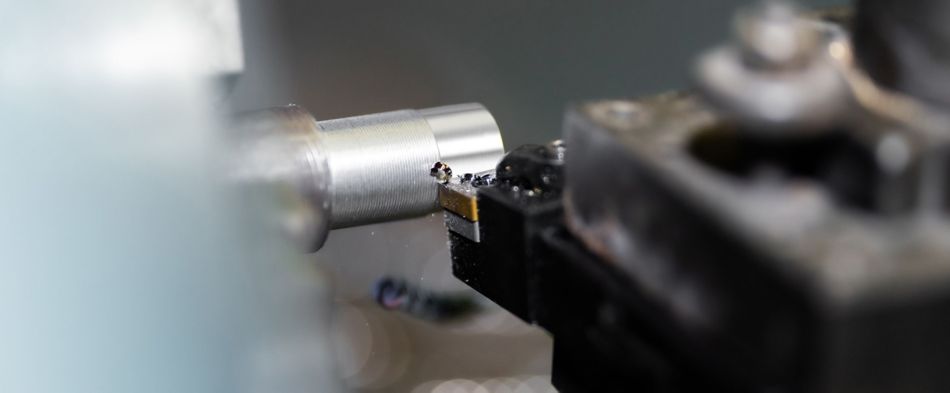

Precision and Power in Every Cut

KCU25B upgrades Kennametal’s existing KCU25 with a newly engineered KENGold™ PVD, multilayer coating that makes machining from one material to another easy while also achieving consistency in cutting. The nano-composite coating has an enhanced coating adhesion that delivers better flank and chipping resistance. Upgrade your multi-material projects and beat deadlines when working on steels, stainless steels, cast iron, high-temp alloys and non-ferrous materials.

KCU25B is available for a variety of insert styles and applications.

- A2: Cut-off

- A4: Grooving, Turning & Cut-off

- K-Lock: R-style

- Fix-Perfect: C-style, D-style, E-style

- Beyond Evolution: Grooving, Turning & Cut-off

- Kenloc: C-style, D-style, S-style, T-style, V-style, W-style

- Top Notch: D-style, V-style, K-style

- Screw-on: C-style, D-style, R-style, S-style, T-style, V-style, W-style