Product Similar To :

CNMG

Kenloc™ Inserts

Material Number1160199

ISO Catalog IDCNMG190608ANSI Catalog IDCNMG642

- P Steel

- M Stainless Steel

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1160199 |

| ISO Catalog ID | CNMG190608 |

| ANSI Catalog ID | CNMG642 |

| Grade | KC850 |

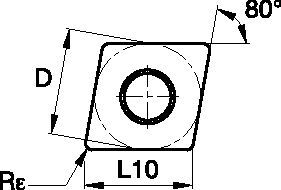

| [D] Insert IC Size | 19.05 mm |

| [D] Insert IC Size | 0.75 in |

| [L10] Insert Cutting Edge Length | 19.344 mm |

| [L10] Insert Cutting Edge Length | 0.7616 in |

| [S] Insert Thickness | 6.35 mm |

| [S] Insert Thickness | 0.25 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| [D1] Insert Hole Size | 7.93 mm |

| [D1] Insert Hole Size | 0.3125 in |

Workpiece Materials

- Steel

- Stainless Steel

Grades

KC850

composition: A CVD tri-phase coating on an extra-strong, cobalt-enriched

alloyed substrate.

application: Designed for heavy cutting of low-, medium-, and high-carbon

steels, medium hardness alloy and tool steels, stainless steels, and some

high-temperature alloys. Excellent thermal and mechanical shock resistance

makes grade KC850 ideally suited for difficult drilling applications.

Used in inserts for Kendex/Metcut drill bodies.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use