Product Similar To :

Cartridges for KSCM AluMill™

Cartridges • KSCM AluMill

Material Number2884902

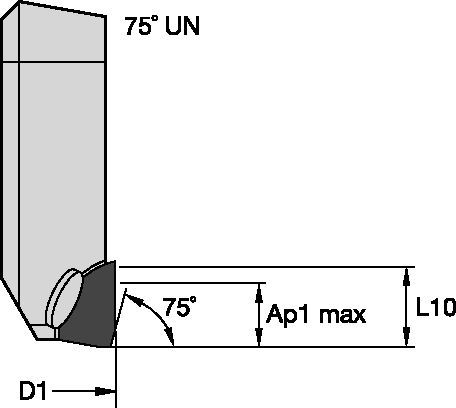

ISO Catalog IDKSCMCA75UNANSI Catalog IDKSCMCA75UN

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 2884902 |

| ISO Catalog ID | KSCMCA75UN |

| ANSI Catalog ID | KSCMCA75UN |

| Grade | KD1400 |

| [KRI] Lead Angle ISO | 75 |

| MAR_KAPPA_R_ANSI | 15 |

| [L10] Cutting Edge Length | 6.1 mm |

| [L10] Cutting Edge Length | 0.2402 in |

| Average Chip Thickness [HM] | 0.02 mm |

| Average Chip Thickness [HM] | 0.0008 in |

Workpiece Materials

- Non-Ferrous

Grades

KD1400

A PCD-tip brazed to a carbide carrier for high-speed machining of non-ferrous materials. KD1400 has excellent chipping resistance with good wear characteristics. Coolant is preferred.

Features and benefits

- PCD cartridge for aluminium face milling.

- Ap1 max = 3mm (0.118″).

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| KCSM… | 0,12 | 0,35 | 0,58 | 0,08 | 0,25 | 0,42 | 0,06 | 0,19 | 0,31 | 0,06 | 0,16 | 0,27 | 0,05 | 0,15 | 0,25 | KCSM… |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| KCSM… | .005 | .014 | .023 | .003 | .010 | .017 | .003 | .008 | .013 | .002 | .007 | .011 | .002 | .006 | .010 | KCSM… |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [m/min]

| Material Group | KD1420 | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1–2 | 4810 | 4205 | 3585 |

| 3 | 1920 | 1795 | 1685 | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| H | 1 | – | – | – |

Recommended Starting Speeds [SFM]

| Material Group | KD1420 | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1–2 | 15780 | 13800 | 11760 |

| 3 | 6300 | 5880 | 5520 | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| H | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

Insert Selection

Cartridge Selection Guide

| Material Group | Light | General | Heavy | |||

| (Light geometry) | – | (Strong geometry) | ||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | KCSM… | KD1420 | KCSM… | KD1420 | KCSM… | KD1420 |

| N3 | KCSM… | KD1420 | KCSM… | KD1420 | KCSM… | KD1420 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use