Product Similar To:

VNMA

Kenloc™ Inserts

Material Number3758162

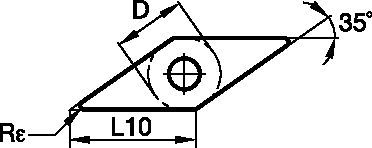

ISO Catalog IDVNMA160408ANSI Catalog IDVNMA332

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3758162 |

| ISO Catalog ID | VNMA160408 |

| ANSI Catalog ID | VNMA332 |

| Grade | KCK20 |

| [D] Insert IC Size | 9.525 mm |

| [D] Insert IC Size | 0.375 in |

| [L10] Insert Cutting Edge Length | 16.606 mm |

| [L10] Insert Cutting Edge Length | 0.6538 in |

| [S] Insert Thickness | 4.76 mm |

| [S] Insert Thickness | 0.1875 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| [D1] Insert Hole Size | 3.81 mm |

| [D1] Insert Hole Size | 0.15 in |

Workpiece Materials

- Cast Iron

Grades

KCK20

A new PVD multilayer AlTiN + AlCrN coated carbide with an excellent combination of wear resistance and coating strength. The KCK20 grade is specifically engineered to maximize coating adhesion and edge strength, making this grade ideal in wet interrupted cutting of gray and ductile irons, and can also be used in dry conditions. It can be used in a wide range of applications, from finishing to roughing, to maximize productivity wherever strength and reliability are needed.

Features and benefits

- Beyond™ Drive™ grades included

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use