Product Similar To :

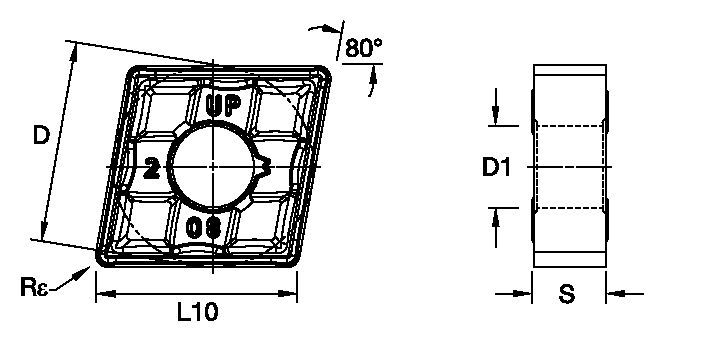

CNMG-UP

Kenloc™ Inserts

Material Number5640978

ISO Catalog IDCNMG120408UPANSI Catalog IDCNMG432UP

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5640978 |

| ISO Catalog ID | CNMG120408UP |

| ANSI Catalog ID | CNMG432UP |

| Grade | KCM15B |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [L10] Insert Cutting Edge Length | 12.896 mm |

| [L10] Insert Cutting Edge Length | 0.5077 in |

| [S] Insert Thickness | 4.763 mm |

| [S] Insert Thickness | 0.1875 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| [D1] Insert Hole Size | 5.16 mm |

| [D1] Insert Hole Size | 0.2031 in |

Workpiece Materials

- Stainless Steel

- High-Temp Alloys

Grades

KCM15B

Composition: A multilayer MTCVD-TiCN-Al2O3 coated carbide grade.

Application: An excellent finishing to medium machining grade for austenitic stainless steels at higher speeds and covers a broad range of steel applications in the P20-25 range. KCM15 grade in combination with unique geometries have been designed to resist depth-of-cut notching and minimize burr formation. The post-coat treatment reduces coating stresses, improves coating adhesion, minimizes microchipping and edge build-up, and improves workpiece finish.

Features and benefits

- Roughing geometry for multiple material groups.

- Beyond™ Drive™ grades included.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use