Product Similar To :

Beyond™ Evolution™ • Modular Blade • Face Grooving • Outboard Sweep • Through Coolant

Grooving, and Cut-Off • External Sweep B

Material Number6117078

ISO Catalog IDEVM50L0312B350999CANSI Catalog IDEVM50L0312B350999C

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

- .caption

Through Coolant: Grooving

Facing

Face Grooving

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Reviews

- Q&A

| Material Number | 6117078 |

| ISO Catalog ID | EVM50L0312B350999C |

| ANSI Catalog ID | EVM50L0312B350999C |

| Insert Size | 3 |

| [DM] Minimum Bore Diameter | 350 mm |

| [DM] Minimum Bore Diameter | 13.78 in |

| [DMAX] Maximum Bore Diameter | 999 mm |

| [DMAX] Maximum Bore Diameter | 39.331 in |

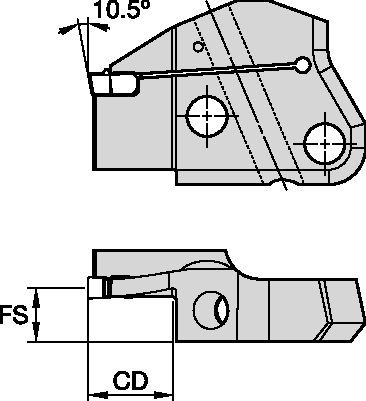

| [CD] Cutting Depth | 12 mm |

| [CD] Cutting Depth | 0.472 in |

| [FS] Secondary F Dimension | 10.5 mm |

| [FS] Secondary F Dimension | 0.413 in |

| Cartridge Size | 50 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

- .caption

Uses and application

Through Coolant: Grooving

Facing

Face Grooving

Features and benefits

- Covers a wide range of face grooving applications.

- Ability to accommodate a wider range of materials with larger grooving widths.

- Modular straight blade design requires coolant for improved performance.

- Blades are easy to use and can be switched out from modular tool holders fast for increased efficiency.

- Available in left and right hand configuratins.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use