Product Similar To :

KenDrill™ Micro • 25 x D • Internal Coolant • Straight Shank • Metric

Solid Carbide Deep Hole Drill for Small Diameters in Multiple Materials

Material Number7071042

ISO Catalog IDB073A01500ANSI Catalog IDB073A01500

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

Drilling

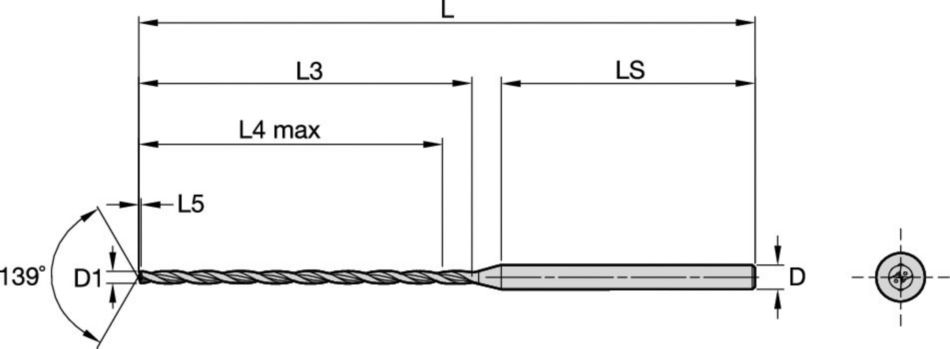

Tool Dimensions: 2flute/4margin/coolant

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 7071042 |

| ISO Catalog ID | B073A01500 |

| ANSI Catalog ID | B073A01500 |

| Grade | KCU10 |

| [D1] Drill Diameter M | 1.5 mm |

| [D1] Drill Diameter M | 0.0591 in |

| [L] Overall Length | 82 mm |

| [L] Overall Length | 3.2283 in |

| [L3] Flute Length | 42.3 mm |

| [L3] Flute Length | 1.6654 in |

| [L4] Maximum Drilling Depth | 37.8 mm |

| [L4] Maximum Drilling Depth | 1.4882 in |

| [L5] Drill Point Length | 0.3 mm |

| [L5] Drill Point Length | 0.0118 in |

| [LS] Shank Length | 35 mm |

| [LS] Shank Length | 1.378 in |

| [D] Adapter / Shank / Bore Diameter | 4 mm |

| [D] Adapter / Shank / Bore Diameter | 0.1575 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Uses and application

Drilling

Tool Dimensions: 2flute/4margin/coolant

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Grades

KCU10

Composition: An advanced multilayer PVD coating over a very deformation-resistant unalloyed carbide substrate. The new and improved coating improves edge stability with wide range speed and feed capabilities.

Application: The KCU10™ grade is ideal for finishing to general machining of most workpiece materials at a wide range of speed and feed capabilities. Excellent for machining most steels, stainless steels, cast irons, non-ferrous materials, and super alloys with improved edge toughness and higher cutting speed/feed capability.

Features and benefits

- High coolant volume supply ensures efficient chip evacuation.

- Micro drilling of short and deep holes on swiss style lathe or machining centers.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Cutting Speed | Feed rate (f) = IPR by diameter | |||||||

| Material | Min | Starting Value | Max | .039 | .059 | .079 | .098 | .114 |

| P | ||||||||

| 0 | 100 | 210 | 330 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 1 | 100 | 210 | 330 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 2 | 100 | 210 | 330 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 3 | 100 | 210 | 330 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 4 | 100 | 210 | 330 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 5 | 70 | 200 | 330 | .0006 | .0008 | .0010 | .0012 | .0013 |

| 6 | 70 | 200 | 330 | .0006 | .0008 | .0010 | .0012 | .0013 |

| M | ||||||||

| 1 | 70 | 200 | 330 | .0004 | .0006 | .0008 | .0010 | .0011 |

| 2 | 70 | 200 | 330 | .0004 | .0006 | .0008 | .0010 | .0011 |

| 3 | 70 | 200 | 330 | .0004 | .0006 | .0008 | .0010 | .0011 |

| K | ||||||||

| 1 | 130 | 230 | 330 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 2 | 130 | 230 | 330 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 3 | 130 | 230 | 330 | .0008 | .0012 | .0016 | .0020 | .0023 |

| N | ||||||||

| 1 | 330 | 460 | 590 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 2 | 330 | 460 | 590 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 3 | 330 | 460 | 590 | .0008 | .0012 | .0016 | .0020 | .0023 |

| 4 | 330 | 460 | 590 | .0008 | .0012 | .0016 | .0020 | .0023 |

| S | ||||||||

| 1 | 30 | 100 | 160 | .0004 | .0006 | .0008 | .0010 | .0011 |

| 2 | 30 | 100 | 160 | .0004 | .0006 | .0008 | .0010 | .0011 |

| 3 | 30 | 100 | 160 | .0004 | .0006 | .0008 | .0010 | .0011 |

| 4 | 30 | 100 | 160 | .0004 | .0006 | .0008 | .0010 | .0011 |

| Cutting Speed | Feed rate (f) = mm/r by diameter | |||||||

| Material | Min | Starting Value | Max | 1,0 | 1,5 | 2,0 | 2,5 | 2,9 |

| P | ||||||||

| 0 | 30 | 65 | 100 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 1 | 30 | 65 | 100 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 2 | 30 | 65 | 100 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 3 | 30 | 65 | 100 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 4 | 30 | 65 | 100 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 5 | 20 | 60 | 100 | 0,015 | 0,020 | 0,025 | 0,030 | 0,034 |

| 6 | 20 | 60 | 100 | 0,015 | 0,020 | 0,025 | 0,030 | 0,034 |

| M | ||||||||

| 1 | 20 | 60 | 100 | 0,010 | 0,015 | 0,020 | 0,025 | 0,029 |

| 2 | 20 | 60 | 100 | 0,010 | 0,015 | 0,020 | 0,025 | 0,029 |

| 3 | 20 | 60 | 100 | 0,010 | 0,015 | 0,020 | 0,025 | 0,029 |

| K | ||||||||

| 1 | 40 | 70 | 100 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 2 | 40 | 70 | 100 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 3 | 40 | 70 | 100 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| N | ||||||||

| 1 | 100 | 140 | 180 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 2 | 100 | 140 | 180 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 3 | 100 | 140 | 180 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| 4 | 100 | 140 | 180 | 0,020 | 0,030 | 0,040 | 0,050 | 0,058 |

| S | ||||||||

| 1 | 10 | 30 | 50 | 0,010 | 0,015 | 0,020 | 0,025 | 0,029 |

| 2 | 10 | 30 | 50 | 0,010 | 0,015 | 0,020 | 0,025 | 0,029 |

| 3 | 10 | 30 | 50 | 0,010 | 0,015 | 0,020 | 0,025 | 0,029 |

| 4 | 10 | 30 | 50 | 0,010 | 0,015 | 0,020 | 0,025 | 0,029 |

I have read and accepted the Terms & Conditions of use