Product Similar To :

KenDrill™ FBG • 3 x D • Internal Coolant • Straight Shank • Metric

Solid Carbide Flat Bottom Drill for Steel and Cast Iron

Material Number7137666

ISO Catalog IDB707A04500FBGANSI Catalog IDB707A04500FBG

- P Steel

- K Cast Iron

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: Flat Bottom

Drilling: Convex

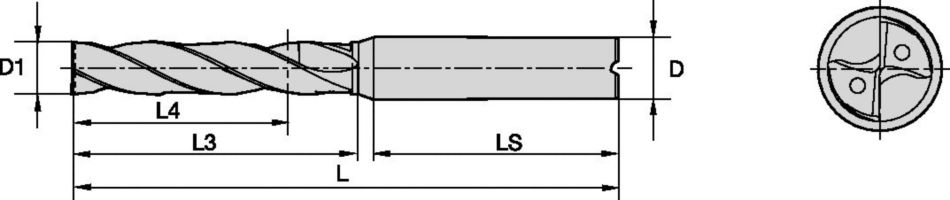

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

DIN number 6537

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Corner Style: Corner Chamfer

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Corner Style: Corner Chamfer

Corner Style: Square End

Drilling Depth: 3x

Counter Boring

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 7137666 |

| ISO Catalog ID | B707A04500FBG |

| ANSI Catalog ID | B707A04500FBG |

| Grade | KCU15 |

| [D1] Drill Diameter M | 4.5 mm |

| [D1] Drill Diameter M | 0.1772 in |

| [L] Overall Length | 66 mm |

| [L] Overall Length | 2.5984 in |

| [L3] Flute Length | 24 mm |

| [L3] Flute Length | 0.9449 in |

| [L4] Maximum Drilling Depth | 17 mm |

| [L4] Maximum Drilling Depth | 0.6693 in |

| [L5] Drill Point Length | 0.22 mm |

| [L5] Drill Point Length | 0.0087 in |

| [LS] Shank Length | 36 mm |

| [LS] Shank Length | 1.4173 in |

| [D] Adapter / Shank / Bore Diameter | 6 mm |

| [D] Adapter / Shank / Bore Diameter | 0.2362 in |

Workpiece Materials

- Steel

- Cast Iron

Uses and application

Drilling

Drilling: Inclined Entry

Drilling: Inclined Exit

Drilling: Flat Bottom

Drilling: Convex

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

DIN number 6537

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Corner Style: Corner Chamfer

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Corner Style: Corner Chamfer

Corner Style: Square End

Drilling Depth: 3x

Counter Boring

Drilling: Cross-Hole Drilling

Features and benefits

- Flat bottom drills with through coolant.

- Application-specific SC drills that combine two operations in one:1) Eliminate the 180° end mill in flat-bottom drilling or when preparing an inclined or curved surface for drilling.2) After full cylindrical engagement, the drill runs at normal solid carbide drilling parameters.

- Unique FB drill-point design with two effective cutting edges over center enable high feed rates.

- Creates a true flat-bottom hole from O.D. to center.

- Four-margin land design improves hole straightness and roundness and provides good alignment, even when drilling cross holes.

- Three grades-geometry-combinations available to cover most common materials.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

Flat-Bottom Drills • B707_FBG Series • Grade KC7315™ • Through Coolant • Drill Diameters 3–20mm • Metric

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 100 | 133 | 170 | mm/r | 0,06–0,14 | 0,10–0,17 | 0,09–0,20 | 0,11–0,25 | 0,18–0,28 | 0,14–0,31 | 0,16–0,37 | 0,19–0,42 |

| 1 | 100 | 133 | 170 | mm/r | 0,07–0,16 | 0,12–0,20 | 0,10–0,23 | 0,13–0,29 | 0,21–0,33 | 0,17–0,37 | 0,19–0,44 | 0,22–0,49 | |

| 2 | 130 | 150 | 180 | mm/r | 0,07–0,13 | 0,10–0,16 | 0,16–0,19 | 0,13–0,23 | 0,18–0,27 | 0,17–0,30 | 0,19–0,35 | 0,22–0,39 | |

| 3 | 80 | 106 | 130 | mm/r | 0,09–0,16 | 0,13–0,20 | 0,13–0,23 | 0,16–0,24 | 0,20–0,31 | 0,21–0,37 | 0,25–0,44 | 0,28–0,46 | |

| 4 | 70 | 98 | 130 | mm/r | 0,08–0,16 | 0,12–0,19 | 0,11–0,22 | 0,14–0,27 | 0,21–0,31 | 0,18–0,35 | 0,21–0,41 | 0,24–0,46 | |

| 5 | 30 | 40 | 60 | mm/r | 0,06–0,12 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,16–0,26 | 0,18–0,28 | 0,22–0,36 | 0,26–0,42 | |

| 6 | 30 | 40 | 60 | mm/r | 0,05–0,17 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | |

| K | 1 | 70 | 85 | 100 | mm/r | 0,09–0,17 | 0,13–0,21 | 0,12–0,25 | 0,15–0,31 | 0,23–0,35 | 0,20–0,39 | 0,23–0,46 | 0,26–0,52 |

| 2 | 100 | 113 | 130 | mm/r | 0,09–0,15 | 0,12–0,18 | 0,12–0,21 | 0,15–0,26 | 0,21–0,30 | 0,20–0,33 | 0,23–0,39 | 0,26–0,44 | |

| 3 | 70 | 105 | 140 | mm/r | 0,07–0,13 | 0,10–0,16 | 0,11–0,19 | 0,13–0,23 | 0,18–0,27 | 0,17–0,30 | 0,20–0,35 | 0,22–0,37 | |

| Material |  |  | |||||||||||

| Material | Cutting Speed | Inch | |||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| P | 0 | 330 | 440 | 560 | IPR | .002–.006 | .004–.007 | .004–.008 | .004–.010 | .007–.011 | .006–.012 | .006–.015 | .008–.017 |

| 1 | 330 | 440 | 560 | IPR | .003–.006 | .005–.008 | .004–.009 | .005–.011 | .008–.013 | .007–.015 | .008–.017 | .009–.019 | |

| 2 | 430 | 490 | 590 | IPR | .003–.005 | .004–.006 | .006–.008 | .005–.009 | .007–.011 | .007–.012 | .008–.014 | .009–.015 | |

| 3 | 260 | 350 | 430 | IPR | .004–.006 | .005–.008 | .005–.009 | .006–.009 | .008–.012 | .008–.015 | .010–.017 | .011–.018 | |

| 4 | 230 | 320 | 430 | IPR | .003–.006 | .005–.008 | .004–.009 | .006–.011 | .008–.012 | .007–.014 | .008–.016 | .009–.018 | |

| 5 | 100 | 130 | 200 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.009 | .006–.010 | .007–.011 | .009–.014 | .010–.017 | |

| 6 | 100 | 130 | 200 | IPR | .002–.003 | .002–.004 | .003–.006 | .004–.007 | .005–.009 | .006–.009 | .007–.013 | .009–.016 | |

| K | 1 | 230 | 280 | 330 | IPR | .004–.007 | .005–.008 | .005–.010 | .006–.012 | .009–.014 | .008–.015 | .009–.018 | .010–.021 |

| 2 | 330 | 370 | 430 | IPR | .004–.006 | .005–.007 | .005–.008 | .006–.010 | .008–.012 | .008–.013 | .009–.015 | .010–.017 | |

| 3 | 230 | 340 | 460 | IPR | .003–.005 | .004–.006 | .004–.008 | .005–.009 | .007–.011 | .007–.012 | .008–.014 | .009–.015 | |

|  | ||||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Material | Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 0 | 100 | 133 | 170 | mm/r | 0,06–0,14 | 0,10–0,17 | 0,09–0,20 | 0,11–0,25 | 0,18–0,28 | 0,14–0,31 | 0,16–0,37 | 0,19–0,42 |

| 1 | 100 | 133 | 170 | mm/r | 0,07–0,16 | 0,12–0,20 | 0,10–0,23 | 0,13–0,29 | 0,21–0,33 | 0,17–0,37 | 0,19–0,44 | 0,22–0,49 | |

| 2 | 130 | 150 | 180 | mm/r | 0,07–0,13 | 0,10–0,16 | 0,16–0,19 | 0,13–0,23 | 0,18–0,27 | 0,17–0,30 | 0,19–0,35 | 0,22–0,39 | |

| 3 | 80 | 106 | 130 | mm/r | 0,09–0,16 | 0,13–0,20 | 0,13–0,23 | 0,16–0,24 | 0,20–0,31 | 0,21–0,37 | 0,25–0,44 | 0,28–0,46 | |

| 4 | 70 | 98 | 130 | mm/r | 0,08–0,16 | 0,12–0,19 | 0,11–0,22 | 0,14–0,27 | 0,21–0,31 | 0,18–0,35 | 0,21–0,41 | 0,24–0,46 | |

| 5 | 30 | 40 | 60 | mm/r | 0,06–0,12 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,16–0,26 | 0,18–0,28 | 0,22–0,36 | 0,26–0,42 | |

| 6 | 30 | 40 | 60 | mm/r | 0,05–0,17 | 0,06–0,10 | 0,08–0,14 | 0,10–0,18 | 0,12–0,22 | 0,14–0,24 | 0,18–0,32 | 0,23–0,41 | |

| K | 1 | 70 | 85 | 100 | mm/r | 0,09–0,17 | 0,13–0,21 | 0,12–0,25 | 0,15–0,31 | 0,23–0,35 | 0,20–0,39 | 0,23–0,46 | 0,26–0,52 |

| 2 | 100 | 113 | 130 | mm/r | 0,09–0,15 | 0,12–0,18 | 0,12–0,21 | 0,15–0,26 | 0,21–0,30 | 0,20–0,33 | 0,23–0,39 | 0,26–0,44 | |

| 3 | 70 | 105 | 140 | mm/r | 0,07–0,13 | 0,10–0,16 | 0,11–0,19 | 0,13–0,23 | 0,18–0,27 | 0,17–0,30 | 0,20–0,35 | 0,22–0,37 | |

Tolerance

| Tolerance • Inch | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

| Tolerance • Metric | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

Dimension

Dimensions for Kennametal Solid Carbide Drills

| short | long | extra long | |||||||||

| Ø | DIN 6535 | ~3 x D | ~5 x D | ~8 x D | |||||||

| D1 | D | LS min | L | L3 | L4 | L | L3 | L4 | L | L3 | L4 |

| -1.40 | 4 | 28 | 58 | 7 | 5 | 58 | 9 | 6 | 58 | 12 | 10 |

| -1.90 | 4 | 28 | 58 | 9 | 6 | 58 | 12 | 9 | 58 | 18 | 15 |

| -2.30 | 4 | 28 | 58 | 13 | 9 | 58 | 18 | 14 | 66 | 26 | 22 |

| -2.99 | 4 | 28 | 58 | 17 | 12 | 58 | 22 | 17 | 66 | 30 | 25 |

| -3.75 | 6 | 36 | 62 | 20 | 14 | 66 | 28 | 23 | 78 | 40 | 33 |

| -4.75 | 6 | 36 | 66 | 24 | 17 | 74 | 36 | 29 | 87 | 49 | 41 |

| -6.00 | 6 | 36 | 66 | 28 | 20 | 82 | 44 | 35 | 94 | 56 | 48 |

| -7.00 | 8 | 36 | 79 | 34 | 24 | 91 | 53 | 43 | 105 | 67 | 57 |

| -8.00 | 8 | 36 | 79 | 41 | 29 | 91 | 53 | 43 | 110 | 72 | 61 |

| -10.00 | 10 | 40 | 89 | 47 | 35 | 103 | 61 | 49 | 122 | 80 | 68 |

| -12.00 | 12 | 45 | 102 | 55 | 40 | 118 | 71 | 56 | 141 | 94 | 79 |

| -14.00 | 14 | 45 | 107 | 60 | 43 | 124 | 77 | 60 | 155 | 108 | 91 |

| -16.00 | 16 | 48 | 115 | 65 | 45 | 133 | 83 | 63 | 171 | 121 | 101 |

| -18.00 | 18 | 48 | 123 | 73 | 51 | 143 | 93 | 71 | 185 | 135 | 113 |

| -20.00 | 20 | 50 | 131 | 79 | 55 | 153 | 101 | 77 | 200 | 148 | 124 |

| -22.00 | 20 | 50 | 141 | 86 | 60 | 167 | 112 | 85 | 217 | 162 | 136 |

| -25.00 | 25 | 56 | 153 | 95 | 65 | 184 | 126 | 98 | 238 | 180 | 150 |

I have read and accepted the Terms & Conditions of use