Product Similar To:

Drill Fix™ DFT™ • MD Inserts

Drill Fix™ DFT™ • MD Inserts

Material Number1713513

ISO Catalog IDDFT05T308MDANSI Catalog IDDFT05T308MD

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1713513 |

| ISO Catalog ID | DFT05T308MD |

| ANSI Catalog ID | DFT05T308MD |

| Grade | KC7140 |

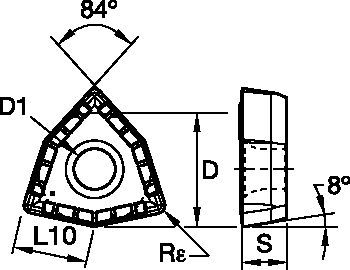

| [L10] Insert Cutting Edge Length | 5.29 mm |

| [L10] Insert Cutting Edge Length | 0.208 in |

| [D] Insert IC Size | 8 mm |

| [D] Insert IC Size | 0.315 in |

| [D1] Insert Hole Size | 3.4 mm |

| [D1] Insert Hole Size | 0.134 in |

| [S] Insert Thickness | 3.75 mm |

| [S] Insert Thickness | 0.148 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

Grades

KC7140

Composition: PVD TiCN/TiN coated medium-grain carbide with high toughness.

Application: Best suited for machining of steel and stainless steel. This exceptionally tough grade is perfectly suited for metastable machining conditions offering excellent tool life.

Features and benefits

- Positive chipbreaker geometry preferred for unstable cutting on longer chipping materials at high feed rates

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use