Product Similar To:

FIX-PERFECT™ 20° • Cast Iron • Shell Mills • SPHX1205... • Inch

Shell Mills • SPHX1205...

Material Number1724396

ISO Catalog ID200C24RP70SP12C4WUFPANSI Catalog ID200C24RP70SP12C4WUFP

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

Face Milling

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 1724396 |

| ISO Catalog ID | 200C24RP70SP12C4WUFP |

| ANSI Catalog ID | 200C24RP70SP12C4WUFP |

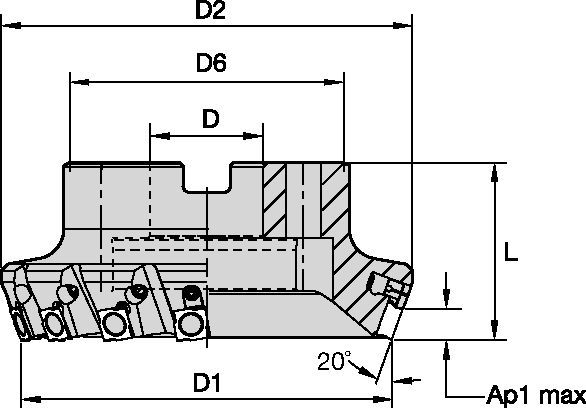

| [D1] Effective Cutting Diameter | 203.2 mm |

| [D1] Effective Cutting Diameter | 8 in |

| [D] Adapter / Shank / Bore Diameter | 63.5 mm |

| [D] Adapter / Shank / Bore Diameter | 2.5 in |

| [D2] Maximum Body Diameter | 216 mm |

| [D2] Maximum Body Diameter | 8.5039 in |

| [D4] Bolt Circle 4 | 101.6 mm |

| [D4] Bolt Circle 3 | 4 in |

| [D6] Hub Diameter | 130.048 mm |

| [D6] Hub Diameter | 5.12 in |

| [L] Overall Length | 60.325 mm |

| [L] Overall Length | 2.375 in |

| [AP1MAX] 1st Maximum Cutting Depth | 5.89 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.232 in |

| Number of Inserts | 24 |

| Number of Adjustable Inserts | 4 |

| Weight Pounds | 15.2 |

| Max RPM | 2149 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

Uses and application

Face Milling

Milling - Side and Face

Features and benefits

- Eight cutting edges per insert.

- Rough and finish in one operation.

- Tangential mounted inserts deliver higher feed rates.

- Adjustable pockets (D1 = 3–10").

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [IPT]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | .006 | .020 | .038 | .004 | .014 | .027 | .003 | .011 | .020 | .003 | .009 | .018 | .002 | .009 | .016 | .E..GP |

| .T..GP | .010 | .025 | .040 | .007 | .018 | .029 | .005 | .013 | .021 | .005 | .012 | .019 | .004 | .011 | .017 | .T..GP |

| .S..GP | .010 | .025 | .040 | .007 | .018 | .029 | .005 | .013 | .021 | .005 | .012 | .019 | .004 | .011 | .017 | .S..GP |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GP | .005 | .020 | .035 | .004 | .014 | .025 | .003 | .011 | .019 | .002 | .009 | .016 | .002 | .009 | .015 | .E..GP |

| .S..GP | .010 | .025 | .040 | .007 | .018 | .029 | .005 | .013 | .021 | .005 | .012 | .019 | .004 | .011 | .017 | .S..GP |

| Light | General | Heavy |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | KB1340 | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 5400 | 3600 | 1920 | 1060 | 960 | 850 | 1660 | 1510 | 1340 | 910 | 770 | 640 | 1160 | 1050 | 940 | 3170 | 2880 | 2560 |

| 2 | – | – | – | 830 | 740 | 700 | 1310 | 1170 | 1090 | 720 | 590 | 520 | 920 | 830 | 760 | 2510 | 2240 | 2090 | |

| 3 | – | – | – | 700 | 620 | 560 | 1100 | 980 | 900 | 600 | 500 | 420 | 770 | 690 | 640 | 2110 | 1870 | 1720 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Material Group | K110M | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 510 | 480 | 450 | 1060 | 960 | 850 | 1660 | 1510 | 1340 | 910 | 770 | 640 | 1160 | 1050 | 940 | 3170 | 2880 | 2560 |

| 2 | 450 | 420 | 390 | 830 | 740 | 700 | 1310 | 1170 | 1090 | 720 | 590 | 520 | 920 | 830 | 760 | 2510 | 2240 | 2090 | |

| 3 | 400 | 350 | 310 | 700 | 620 | 560 | 1100 | 980 | 900 | 600 | 500 | 420 | 770 | 690 | 640 | 2110 | 1870 | 1720 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Insert Selection

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCK15 |

| K3 | .E..GP | KC520M | .E..GP | KCK15 | .S..GP | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GP | KCK15 | .E..GP | KCK15 | .E..GP | KCK15 |

| K3 | .E..GP | KCK15 | .E..GP | KCK15 | .S..GP | KCPK30 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use