Product Similar To:

FIX8™ • Toolholder • PCJN • -3° • Through Coolant • Inch

Heavy-Duty Turning • Square Shank

Material Number6913117

ISO Catalog IDFIX8PCJNL166DCANSI Catalog IDFIX8PCJNL166DC

- P Steel

- K Cast Iron

- .caption

Turning

Facing

Chamfering

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 6913117 |

| ISO Catalog ID | FIX8PCJNL166DC |

| ANSI Catalog ID | FIX8PCJNL166DC |

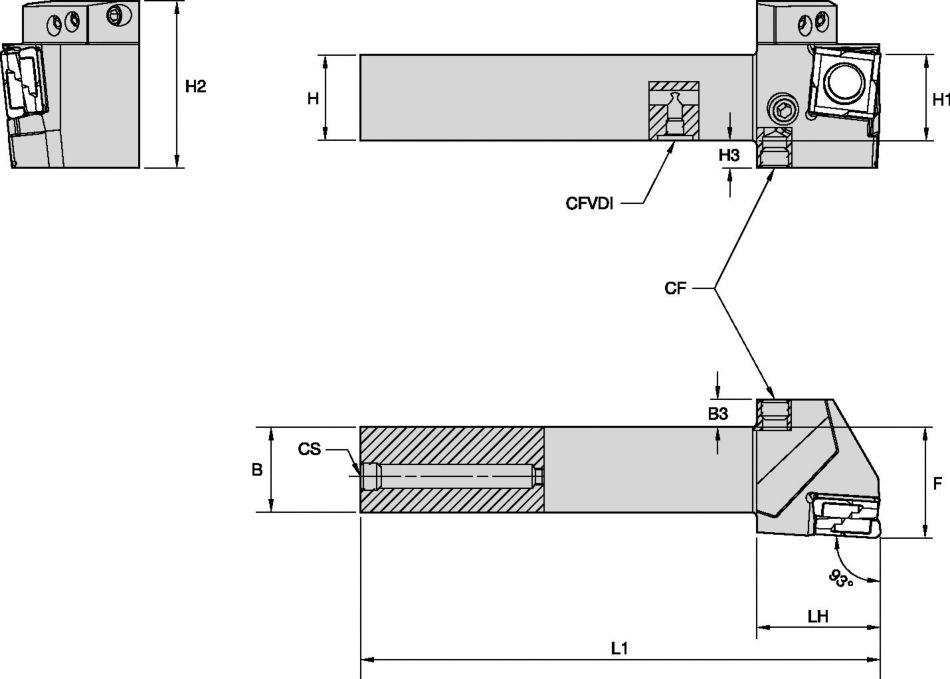

| [H] Shank Height | 25.4 mm |

| [H] Shank Height | 1 in |

| [H1] Cutting Height | 25.4 mm |

| [H1] Cutting Height | 1 in |

| [H3]Head Bottom Offset | 8 mm |

| [H3]Head Bottom Offset | 0.315 in |

| [B] Shank Width | 25.4 mm |

| [B] Shank Width | 1 in |

| [B3] Head Back Offset | 8 mm |

| [B3] Head Back Offset | 0.315 in |

| [L1] Tool Length | 152.4 mm |

| [L1] Tool Length | 6 in |

| [LH] Head Length | 36 mm |

| [LH] Head Length | 1.4173 in |

| [F] F Dimension | 31.75 mm |

| [F] F Dimension | 1.25 in |

| [CS] Coolant Supply Size | M8 X 1 |

| [CFVDI] Coolant Supply Size VDI | M4 X 0.7 |

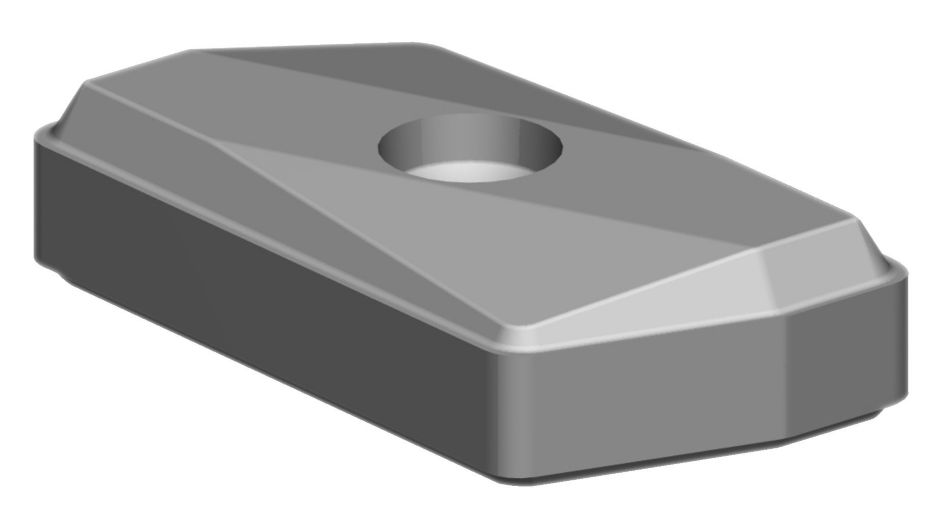

| Gage Insert | CNUX191016L |

Workpiece Materials

- Steel

- Cast Iron

- .caption

Uses and application

Turning

Facing

Chamfering

Features and benefits

- Eight cutting edges per insert

- Precision 3D coolant technology supplied directly to the cutting edge

- Low cutting forces and excellent chip control

- Heavy-duty chip geometry for the largest feed rates

- High cutting-edge edge strength, rigid clamping system

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use