Product Similar To:

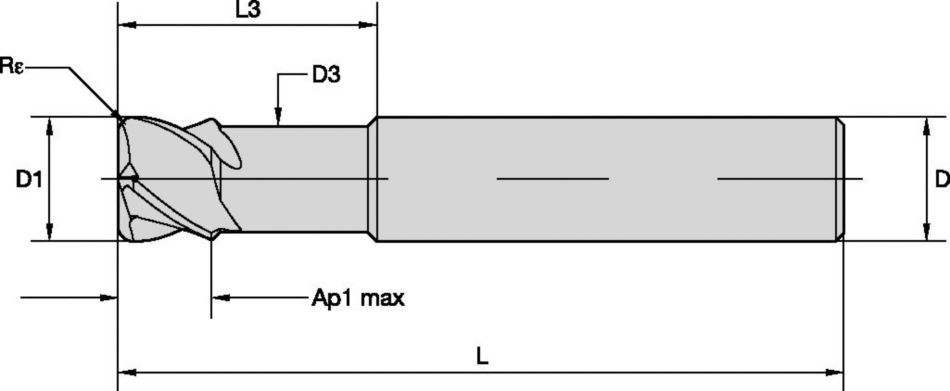

KenCut™ HT • EADE • Radiused • 4 Flutes • Necked • Plain Shank • Inch

Full Ceramic End Mill for Roughing of Nickel Based Alloys

Material Number5352319

ISO Catalog IDEADE0178J4AQXANSI Catalog IDEADE0178J4AQX

Ramping: 2°

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 4

Helix Angle: 40°

Corner Style: Corner Radius

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5352319 |

| ISO Catalog ID | EADE0178J4AQX |

| ANSI Catalog ID | EADE0178J4AQX |

| Grade | KYS40 |

| Adapter Style Machine Side | Straight-Cylindrical |

| [D1] Effective Cutting Diameter | 4.564 mm |

| [D1] Effective Cutting Diameter | 0.1797 in |

| [D] Adapter / Shank / Bore Diameter | 6.35 mm |

| [D] Adapter / Shank / Bore Diameter | 0.25 in |

| [D3] Neck Diameter | 4.382 mm |

| [D3] Neck Diameter | 0.1725 in |

| [AP1MAX] 1st Maximum Cutting Depth | 3.572 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.1406 in |

| [L3] Usable Length | 9.525 mm |

| [L3] Usable Length | 0.375 in |

| [L] Overall Length | 50.8 mm |

| [L] Overall Length | 2 in |

| [Re] Corner Radius | 0.6 mm |

| [Re] Corner Radius | 0.024 in |

| [Z] Number of Flutes | 4 |

Uses and application

Ramping: 2°

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 4

Helix Angle: 40°

Corner Style: Corner Radius

Features and benefits

- Full ceramic end mills offer highest productivity and tool life in roughing nickel-based high-temperature alloys.

- Cutting speed up to 1000m/min.

- Up to five times higher tool life than solid carbide end mills.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| End Mill Tolerances | |||

| D1 | tolerance e8 | D | tolerance h6 + / - |

| 1/8" | -.00055/.00110" | 1/8" | +0/-.00024" |

| -.00079/-.00150" | +0/-.00031" | ||

| -.00098/-.00185" | +0/-.00035" | ||

| -.00126/-.00232" | +0/-.00043" | ||

| -.00157/-.00287" | +0/-.00051" | ||

Speeds & Feeds

|  |  | ||||||||||

| Side Milling (A) and Slotting (B) | KYS40 | Recommended feed per tooth (IPT=inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||

| A | B | Cutting Speed | D1 | |||||||||

| 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | ||||||||

| Material | ap | ae | ap | min | max | inch | .1875 | .2500 | .3125 | .3750 | .5000 | |

| S | 3 | Ap1 max | 0.1 x D* | 0,5 x D* | 825 | 3300 | IPT | .00094 | .00100 | .00109 | .00113 | .00133 |

I have read and accepted the Terms & Conditions of use