Product Similar To:

KenDrill™ SE • 8 x D • Internal Coolant • Straight Shank • Metric

Solid Carbide Drill for Steels

Material Number1836695

ISO Catalog IDB256A08800ANSI Catalog IDB256A08800

Drilling

Drilling: Inclined Exit

Drilling: Stacked Plates

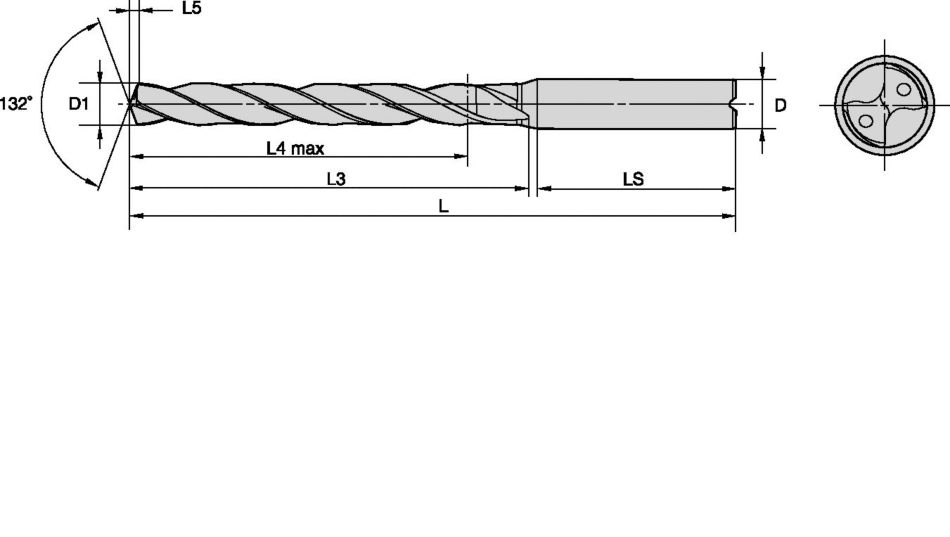

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1836695 |

| ISO Catalog ID | B256A08800 |

| ANSI Catalog ID | B256A08800 |

| Grade | KC7015 |

| [D1] Drill Diameter M | 8.8 mm |

| [D1] Drill Diameter M | 0.3465 in |

| [L] Overall Length | 135 mm |

| [L] Overall Length | 5.315 in |

| [L3] Flute Length | 92 mm |

| [L3] Flute Length | 3.622 in |

| [L4] Maximum Drilling Depth | 80 mm |

| [L4] Maximum Drilling Depth | 3.1496 in |

| [L5] Drill Point Length | 1.75 mm |

| [L5] Drill Point Length | 0.0689 in |

| [LS] Shank Length | 40 mm |

| [LS] Shank Length | 1.5748 in |

| [D] Adapter / Shank / Bore Diameter | 10 mm |

| [D] Adapter / Shank / Bore Diameter | 0.3937 in |

Uses and application

Drilling

Drilling: Inclined Exit

Drilling: Stacked Plates

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

Grades

KC7015

PVD-TIN coated fine grade carbide

High egde strength and transfers rupture strength

For difficult cutting tasks with interrupted cuts

First Choice in solid carbide drills for many steel materials and tough cast iron materials

Also for indexable inserts

Features and benefits

- SE four-margin drills with through coolant for steel.

- Application-specific SC drill for mid-L/D applications that require high accuracy and consistent hole straightness combined with excellent metal removal rates and long tool life, such as in conrods.

- SE drill point design with sculptured edge enables high feed rates.

- KC7315™ grade is a multilayer, TiAlN-based coating with high hot hardness allows 30% higher cutting speeds and constant tool life.

- Four-margin lands improve hole straightness and hole alignment when drilling through cross holes.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

SE Drills • B256 Series • Grade KC7315™ • Through Coolant • Drill Diameters 3–20mm • Metric

| Material |  |  | |||||||||||

| Material | Cutting Speed | Inch | |||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| P | 0 | 430 | 480 | 660 | IPR | .003–.004 | .003–.005 | .004–.005 | .004–.006 | .004–.008 | .005–.009 | .006–.011 | .008–.012 |

| 1 | 390 | 480 | 570 | IPR | .003–.004 | .004–.006 | .004–.006 | .005–.008 | .005–.009 | .006–.011 | .007–.013 | .009–.015 | |

| 2 | 260 | 330 | 390 | IPR | .003–.004 | .003–.005 | .004–.007 | .006–.008 | .006–.010 | .007–.013 | .009–.017 | .010–.020 | |

| 3 | 260 | 300 | 390 | IPR | .003–.004 | .004–.006 | .004–.006 | .005–.008 | .005–.009 | .006–.011 | .007–.013 | .009–.015 | |

| 4 | 200 | 230 | 260 | IPR | .002–.004 | .003–.005 | .004–.005 | .004–.006 | .004–.007 | .005–.009 | .006–.011 | .007–.012 | |

| K | 1 | 390 | 490 | 660 | IPR | .003–.004 | .006–.008 | .008–.011 | .010–.014 | .011–.016 | .013–.017 | .014–.020 | .016–.022 |

| 2 | 260 | 390 | 520 | IPR | .003–.004 | .005–.007 | .008–.010 | .009–.012 | .010–.014 | .012–.016 | .013–.018 | .015–.020 | |

| 3 | 200 | 260 | 390 | IPR | .003–.004 | .004–.006 | .006–.008 | .008–.010 | .009–.012 | .009–.013 | .011–.015 | .012–.016 | |

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 130 | 145 | 200 | mm/r | 0,07–0,09 | 0,08–0,13 | 0,09–0,13 | 0,11–0,16 | 0,11–0,19 | 0,13–0,23 | 0,15–0,28 | 0,19–0,31 |

| 1 | 120 | 145 | 175 | mm/r | 0,08–0,11 | 0,09–0,15 | 0,11–0,15 | 0,13–0,19 | 0,13–0,22 | 0,15–0,27 | 0,18–0,33 | 0,22–0,37 | |

| 2 | 80 | 100 | 120 | mm/r | 0,08–0,11 | 0,08–0,13 | 0,09–0,17 | 0,15–0,21 | 0,16–0,25 | 0,18–0,33 | 0,22–0,42 | 0,26–0,50 | |

| 3 | 80 | 90 | 120 | mm/r | 0,08–0,11 | 0,09–0,15 | 0,11–0,15 | 0,13–0,19 | 0,13–0,22 | 0,15–0,27 | 0,18–0,33 | 0,22–0,37 | |

| 4 | 60 | 70 | 80 | mm/r | 0,06–0,09 | 0,07–0,13 | 0,09–0,13 | 0,11–0,15 | 0,11–0,17 | 0,13–0,22 | 0,15–0,27 | 0,17–0,30 | |

| K | 1 | 120 | 150 | 200 | mm/r | 0,08–0,11 | 0,14–0,20 | 0,20–0,28 | 0,25–0,35 | 0,29–0,40 | 0,32–0,43 | 0,36–0,50 | 0,40–0,55 |

| 2 | 80 | 120 | 160 | mm/r | 0,08–0,11 | 0,13–0,17 | 0,19–0,26 | 0,23–0,30 | 0,25–0,36 | 0,30–0,40 | 0,34–0,46 | 0,37–0,50 | |

| 3 | 60 | 80 | 120 | mm/r | 0,07–0,10 | 0,10–0,14 | 0,15–0,21 | 0,19–0,26 | 0,22–0,30 | 0,24–0,33 | 0,28–0,38 | 0,30–0,41 | |

|  | ||||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Material | Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 0 | 130 | 145 | 200 | mm/dev | 0,07–0,09 | 0,08–0,13 | 0,09–0,13 | 0,11–0,16 | 0,11–0,19 | 0,13–0,23 | 0,15–0,28 | 0,19–0,31 |

| 1 | 120 | 145 | 175 | mm/dev | 0,08–0,11 | 0,09–0,15 | 0,11–0,15 | 0,13–0,19 | 0,13–0,22 | 0,15–0,27 | 0,18–0,33 | 0,22–0,37 | |

| 2 | 80 | 100 | 120 | mm/dev | 0,08–0,11 | 0,08–0,13 | 0,09–0,17 | 0,15–0,21 | 0,16–0,25 | 0,18–0,33 | 0,22–0,42 | 0,26–0,50 | |

| 3 | 80 | 90 | 120 | mm/dev | 0,08–0,11 | 0,09–0,15 | 0,11–0,15 | 0,13–0,19 | 0,13–0,22 | 0,15–0,27 | 0,18–0,33 | 0,22–0,37 | |

| 4 | 60 | 70 | 80 | mm/dev | 0,06–0,09 | 0,07–0,13 | 0,09–0,13 | 0,11–0,15 | 0,11–0,17 | 0,13–0,22 | 0,15–0,27 | 0,17–0,30 | |

Tolerance

| Tolerance • Metric | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

| Tolerance • Inch | ||

| nominal size range | D1 tolerance m7 | D tolerance h6 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

I have read and accepted the Terms & Conditions of use