Product Similar To:

KenFeed™ • KMDA •Torus • 6 Flutes • Plain Shank • Metric

KenFeed™ Solid Carbide End Mill for High Feed Applications in Hard Materials

Material Number3352493

ISO Catalog IDKMDA1600A6ANAANSI Catalog IDKMDA1600A6ANA

- P Steel

- H Hardened Materials

Ramping: Blank

3D Profiling

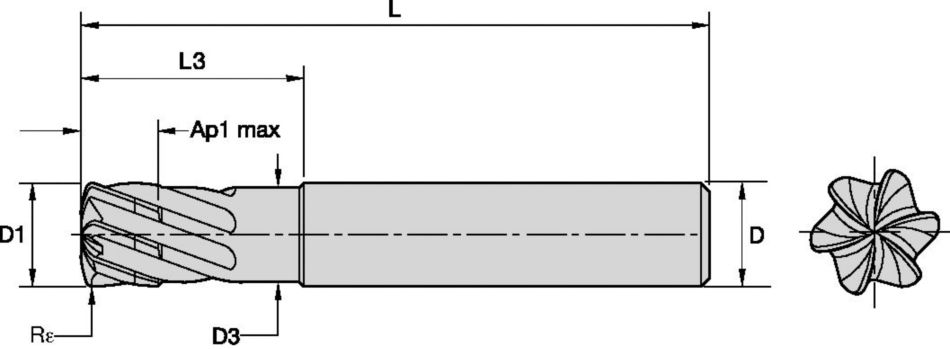

Tool Dimensions: Flute Configuration: 6

Helix Angle: 20°

Corner Style: Torus

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3352493 |

| ISO Catalog ID | KMDA1600A6ANA |

| ANSI Catalog ID | KMDA1600A6ANA |

| Grade | KC639M |

| Adapter Style Machine Side | Straight-Cylindrical |

| [D1] Effective Cutting Diameter | 16 mm |

| [D1] Effective Cutting Diameter | 0.63 in |

| [D] Adapter / Shank / Bore Diameter | 16 mm |

| [D] Adapter / Shank / Bore Diameter | 0.6299 in |

| [D3] Neck Diameter | 15 mm |

| [D3] Neck Diameter | 0.591 in |

| [AP1MAX] 1st Maximum Cutting Depth | 0.84 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.0331 in |

| [L3] Usable Length | 48 mm |

| [L3] Usable Length | 1.89 in |

| [L] Overall Length | 110 mm |

| [L] Overall Length | 4.3307 in |

| [Re] Corner Radius | 1 mm |

| [Re] Corner Radius | 0.039 in |

| [Z] Number of Flutes | 6 |

Workpiece Materials

- Steel

- Hardened Materials

Uses and application

Ramping: Blank

3D Profiling

Tool Dimensions: Flute Configuration: 6

Helix Angle: 20°

Corner Style: Torus

Grades

KC639M

PVD- (AlTiN) coated carbide on a submicron carbide substrate. This hard coating provides outstanding performance in milling hardened materials (58–65 HRC).

Features and benefits

- KenFeed solid carbide end mills perform roughing and finishing by taking very shallow-depth cuts at extremely high feed rates to maximize metal removal rates.

- For hardened materials up to 52HRC.

- Solid carbide end mill for face milling applications.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| End Mill Tolerances | |||

| D1 | tolerance e8 | D | tolerance h6 + / - |

| ≤3 | -0,014/-0,028 | ≤3 | +0/-0,006 |

| -0,020/-0,038 | +0/-0,008 | ||

| -0,025/-0,047 | +0/-0,009 | ||

| -0,032/-0,059 | +0/-0,011 | ||

| -0,040/-0,073 | +0/-0,013 | ||

TechnicalInfo

| Geometrical Parameters | Ramping Guide for Circular and Linear Ramping | ||||||||||||

| Circular Interpolation | Linear Ramping | ||||||||||||

| Optimal Range of Circle Diameter for a Single Pass | Calculated Length per Ramp Angle | ||||||||||||

| catalog number | D1 | Ap1 max | R | Rε | YRC | RCN | Smallest | Largest | 1º | 2º | 3º | 4º | 5º |

| KMDA0600A6ANA | 6 | 0,32 | 6 | 0,375 | 0,75 | 1,32 | 8,64 | 12,00 | 18,333 | 9,164 | 6,106 | 4,576 | 3,658 |

| KMDA0800A6ANA | 8 | 0,42 | 8 | 0,500 | 1,00 | 1,76 | 11,52 | 16,00 | 24,062 | 12,027 | 8,014 | 6,006 | 4,801 |

| KMDA1000A6ANA | 10 | 0,53 | 10 | 0,625 | 1,25 | 2,20 | 14,40 | 20,00 | 30,364 | 15,177 | 10,113 | 7,579 | 6,058 |

| KMDA1200A6ANA | 12 | 0,63 | 12 | 0,750 | 1,50 | 2,64 | 17,28 | 24,00 | 36,093 | 18,041 | 12,021 | 9,009 | 7,201 |

| KMDA1600A6ANA | 16 | 0,84 | 16 | 1,000 | 2,00 | 3,52 | 23,04 | 32,00 | 48,124 | 24,054 | 16,028 | 12,013 | 9,601 |

| KMDA2000A6ANA | 20 | 1,05 | 20 | 1,250 | 2,50 | 4,40 | 28,80 | 40,00 | 60,154 | 30,068 | 20,035 | 15,016 | 12,002 |

| recommended degree of programmed feed rate to use while ramping | 100% | 70% | 50% | 30% | 10% | ||||||||

I have read and accepted the Terms & Conditions of use