Product Similar To:

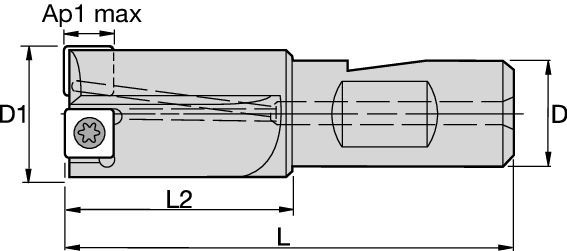

KICR End Mills • 0° Lead • Internal Coolant Holes • Inch

Indexable End Mills

Material Number1023607

ISO Catalog IDKICR175SP4055CANSI Catalog IDKICR175SP4055C

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- .caption

Shank - Cylindrical Weldon

Tapping: Through Coolant

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 1023607 |

| ISO Catalog ID | KICR175SP4055C |

| ANSI Catalog ID | KICR175SP4055C |

| [D1] Effective Cutting Diameter | 44.45 mm |

| [D1] Effective Cutting Diameter | 1.75 in |

| [D] Adapter / Shank / Bore Diameter | 31.75 mm |

| [D] Adapter / Shank / Bore Diameter | 1.25 in |

| [L] Overall Length | 121.41 mm |

| [L] Overall Length | 4.78 in |

| [L2] Head Length | 63.5 mm |

| [L2] Head Length | 2.5 in |

| [AP1MAX] 1st Maximum Cutting Depth | 11.938 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.47 in |

| Number of Inserts | 2 |

| Max RPM | 8750 |

| Gage Insert | SPEB422 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- .caption

Uses and application

Shank - Cylindrical Weldon

Tapping: Through Coolant

Features and benefits

- Center cutting capability — ideal for short-hole drilling and end milling.

- Four cutting edges per insert.

- Twin coolant holes.

- All end mills supplied with Weldon® shank and Whistle Notch™.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Speeds

Recommended Starting Speeds [SFM]

I have read and accepted the Terms & Conditions of use