Product Similar To:

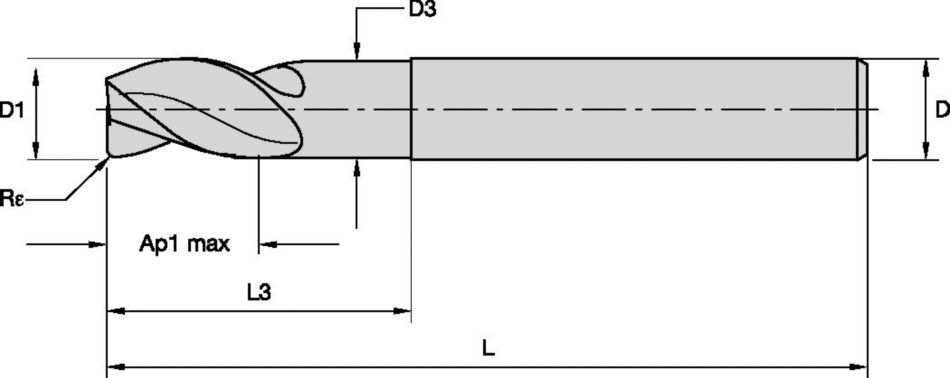

MaxiMet™ • Radiused • 3 Flutes • Necked • Plain Shank • Metric

MaxiMet™ Solid Carbide End Mill for Roughing and Finishing of Aluminum

Material Number5414478

ISO Catalog IDABDE2000A3ARMANSI Catalog IDABDE2000A3ARM

- N Non-Ferrous

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 3

Helix Angle: 38°

Corner Style: Corner Radius

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5414478 |

| ISO Catalog ID | ABDE2000A3ARM |

| ANSI Catalog ID | ABDE2000A3ARM |

| Grade | K600 |

| Adapter Style Machine Side | Straight-Cylindrical |

| [D1] Effective Cutting Diameter | 20 mm |

| [D1] Effective Cutting Diameter | 0.7874 in |

| [D] Adapter / Shank / Bore Diameter | 20 mm |

| [D] Adapter / Shank / Bore Diameter | 0.7874 in |

| [D3] Neck Diameter | 19 mm |

| [D3] Neck Diameter | 0.748 in |

| [AP1MAX] 1st Maximum Cutting Depth | 30 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.1811 in |

| [L3] Usable Length | 60 mm |

| [L3] Usable Length | 2.3622 in |

| [L] Overall Length | 115 mm |

| [L] Overall Length | 4.5276 in |

| [Re] Corner Radius | 3 mm |

| [Re] Corner Radius | 0.118 in |

| [Z] Number of Flutes | 3 |

Workpiece Materials

- Non-Ferrous

Uses and application

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 3

Helix Angle: 38°

Corner Style: Corner Radius

Grades

K600

Carbide grade made from high-quality, micrograin materials for cutting all types of workpiece materials. Very high toughness ensures a controlled wear rate. The micrograin structure enables extremely sharp cutting edges.

Features and benefits

- MaxiMet™ solid carbide end mills are very effective in thin wall applications

- Center cutting for plunging and ramping operations

- Wiper facet, unique end gash and unique flute geometry provide optimum surface finishes

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Material |  |  | K600 | Feed per Tooth — fz information is for side milling (A). | |||||||||

| A | B | Cutting Speed | D1 | ||||||||||

| ap | ae | ap | Min | Max | mm | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| N | 1 | 1 x D | 0,5 x D | 1,0 x D | 500 | 2000 | fz | 0,060 | 0,080 | 0,100 | 0,120 | 0,160 | 0,200 |

| 2 | 1 x D | 0,5 x D | 1,0 x D | 500 | 1500 | fz | 0,054 | 0,072 | 0,090 | 0,108 | 0,144 | 0,180 | |

| 3 | 1 x D | 0,5 x D | 1,0 x D | 500 | 1500 | fz | 0,042 | 0,056 | 0,070 | 0,084 | 0,112 | 0,140 | |

| 4 | 1 x D | 0,5 x D | 1,0 x D | 400 | 750 | fz | 0,042 | 0,056 | 0,070 | 0,084 | 0,112 | 0,140 | |

| 5 | 1 x D | 0,5 x D | 1,0 x D | 250 | 1000 | fz | 0,054 | 0,072 | 0,090 | 0,108 | 0,144 | 0,180 | |

Tolerance

| End Mill Tolerances | ||

| D1 | D1 tolerance | D tolerance |

| 6mm | DIN e8 | DIN h6 |

| DIN h6 | DIN h6 | |

I have read and accepted the Terms & Conditions of use