Product Similar To:

Mill 4-12KT™ • Carbide Insert • LNGQ-L-GE • Left Handed Inserts for Made-To-Order Slotting Cutters

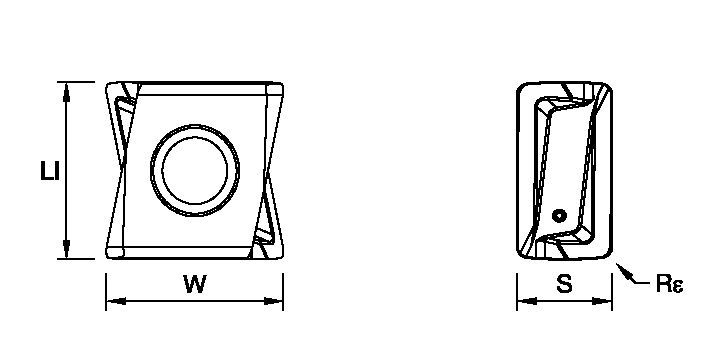

Shoulder milling insert with four cutting edges per insert, precision ground

Material Number6723725

ISO Catalog IDLNGQ120608ELGEKT4ANSI Catalog IDLNGQ120608ELGEKT4

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6723725 |

| ISO Catalog ID | LNGQ120608ELGEKT4 |

| ANSI Catalog ID | LNGQ120608ELGEKT4 |

| Grade | KCK20 |

| [LI] Insert Length | 13 mm |

| [LI] Insert Length | 0.5118 in |

| [S] Insert Thickness | 6.35 mm |

| [S] Insert Thickness | 0.25 in |

| [W] Insert Width | 13.385 mm |

| [W] Insert Width | 0.527 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| Average Chip Thickness [HM] | 0.05 mm |

| Average Chip Thickness [HM] | 0.002 in |

| Cutting Edges per Insert | 4 |

Grades

KCK20

A new PVD multilayer AlTiN + AlCrN coated carbide with an excellent combination of wear resistance and coating strength. The KCK20 grade is specifically engineered to maximize coating adhesion and edge strength, making this grade ideal in wet interrupted cutting of gray and ductile irons, and can also be used in dry conditions. It can be used in a wide range of applications, from finishing to roughing, to maximize productivity wherever strength and reliability are needed.

Features and benefits

- Precision ground insert for best surface finish.

- Advanced insert/pocket interface ensures stability and consistent performance in difficult applications.

- Up to 15% lower power consumption.

- Easy insert indexing through screw clamping.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| Mill 4-12KT™ • Insert Selection Guide | ||||||

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1-P2 | .E..GE | KC522M | .E..PU | KCPM40 | .E..HD | KCPM40 |

| P3-P4 | .E..GE | KC522M | .E..PU | KCPM40 | .E..HD | KCPM40 |

| P5-P6 | .E..GE | KC522M | .E..PU | KC725M | .E..HD | KCPK30 |

| M1-M2 | .E..GE | KC522M | .E..PU | KCSM40 | .E..HD | KCPM40 |

| M3 | .E..GE | KC522M | .E..GE | KCSM40 | .E..HD | KCPM40 |

| K1-K2 | .E..GE | KCK15 | .E..PU | KCK20B | .E..HD | KCK15 |

| K3 | .E..GE | KCK20B | .E..PU | KCK20B | .E..HD | KCK20B |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | .E..GE | KC522M | .E..PU | KCSM40 | – | – |

| S3 | .E..GE | KC522M | .E..GE | KCSM40 | – | – |

| S4 | .E..GE | KC522M | .E..GE | KCSM40 | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use