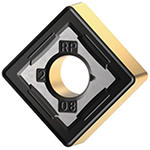

Product Similar To:

Kenloc™ • SNMG Insert • Negative • RP

ISO Turning Carbide Insert • Roughing Positive Geometry

Material Number2461094

ISO Catalog IDSNMG150616RPANSI Catalog IDSNMG544RP

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 2461094 |

| ISO Catalog ID | SNMG150616RP |

| ANSI Catalog ID | SNMG544RP |

| Grade | KU30T |

| [D] Insert IC Size | 15.875 mm |

| [D] Insert IC Size | 0.625 in |

| [L10] Insert Cutting Edge Length | 15.875 mm |

| [L10] Insert Cutting Edge Length | 0.625 in |

| [S] Insert Thickness | 6.35 mm |

| [S] Insert Thickness | 0.25 in |

| [Rε] Corner Radius | 1.6 mm |

| [Rε] Corner Radius | 0.063 in |

| [D1] Insert Hole Size | 6.35 mm |

| [D1] Insert Hole Size | 0.25 in |

Grades

KU30T

composition: A tough cobalt-enriched substrate with a multilayered

CVD coating.

application: KU30T is a new grade designed specifically for the job shop

industry where a wide range of workpiece materials is employed. With

its tough cobalt-enriched substrate, KU30T performs very effectively in

roughing through finishing operations. The post-coat grinding of the

insert permits stable insert seating while the post-coat treatment resists

workpiece build-up and microchipping. For machining steels, cast irons,

and stainless steels, your first choices are the –RN, -MN, and the –RP

geometries. For medium machining and finishing, the –MP and –FP

geometries with a positive rake are suggested.

Features and benefits

- Roughing geometry with positive rake face for chip control in difficult materials

- Beyond™ Drive™ grades included

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use