Product Similar To:

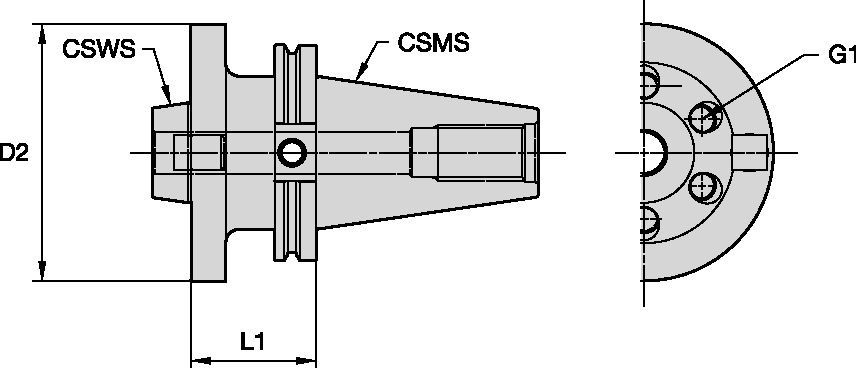

BTF • Taper Flange Adapter • CV50F • Inch

Bolt taper flange adapter for maximum tool stiffness.

Material Number6113578

ISO Catalog IDCV50FBTF46226ANSI Catalog IDCV50FBTF46226

Shank: Flange Mount

Balance - G 6.3@15,000 min -1

Through Coolant: Coolant Entry AD

48909

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6113578 |

| ISO Catalog ID | CV50FBTF46226 |

| ANSI Catalog ID | CV50FBTF46226 |

| [D2] Body Diameter 1 Workpiece Side | 117.475 mm |

| [D2] Body Diameter 1 Workpiece Side | 4.625 in |

| [L1] Gage Length | 57.275 mm |

| [L1] Gage Length | 2.255 in |

| [CSMS] System Size Machine Side | CV50F |

| [CSWS] System Size Workpiece Side | BTF46 |

| Weight Kilograms | 4.95 |

Uses and application

Shank: Flange Mount

Balance - G 6.3@15,000 min -1

Through Coolant: Coolant Entry AD

48909

Features and benefits

- Designed for demanding applications like high-temperature alloy airframe structural parts machining.

- Higher stability than any straight flange connection, adding unequaled bending moment resistance.

- Large volume coolant supply through the center to support chip evacuation and to control heat in the cutting zone.

- Specially designed drive keys for maximum torque transmission.

- Six bolts for secure mounting.

- Taper pilot ensures maximum tool stabilization.

- Not interchangeable with CVKV-Taper Face Tooling.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use