Product Similar To:

TM40 Parallel Cutter Metric

TM40 • Weldon® Shank • Parallel Threads

Material Number5593185

ISO Catalog IDTM40D22L65Z3ANSI Catalog IDTM40D22L65Z3

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

- .caption

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 5593185 |

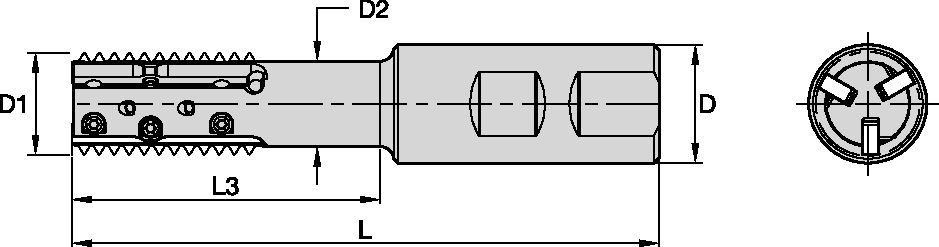

| ISO Catalog ID | TM40D22L65Z3 |

| ANSI Catalog ID | TM40D22L65Z3 |

| [D1] Effective Cutting Diameter | 22 mm |

| [D1] Effective Cutting Diameter | 0.866 in |

| [D] Adapter / Shank / Bore Diameter | 25 mm |

| [D] Adapter / Shank / Bore Diameter | 0.984 in |

| [D2] Maximum Body Diameter | 18 mm |

| [D2] Maximum Body Diameter | 0.709 in |

| [L] Overall Length | 124 mm |

| [L] Overall Length | 4.882 in |

| [L3] Usable Length | 65 mm |

| [L3] Usable Length | 2.559 in |

| Number of Inserts | 3 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

- .caption

Features and benefits

- 22–30mm cutting diameter range.

- For internal and external threading on most types of workpiece materials.

- One tool is used for both right- and left-hand threads.

- All cutters have through-coolant capability.

- Utilizes inserts with various profiles and pitches.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Thread Application per Toolholder | ||||||

| min thread Ø | ||||||

| toolholder | D1 mm | ISO (coarse) | ISO (fine) | UN/UNF/UNEF/UNS | BSF | BSP(G) |

| TM40D22L43Z3 | 22,00 | M27 x 3 | M24 x 1; M24 x 1.5; | 1 11/16–8UN; 1–9UN, | 1–11; 1–12 | 3/4–14 |

| TM40D22L65Z3 | 22,00 | M27 x 3 | M24 x 1; M24 x 1.5; | 1 11/16–8UN; 1–9UN; | 1–11; 1–12 | 3/4–14 |

| TM40D30L55Z4 | 30,00 | – | M32 x 1; M32 x 1.5; | 1 3/8–8UN; 1–9UN; | 1 3/8–11; 1 3/8–12; | 1–11 |

| TM40D30L80Z3 | 30,00 | – | M32 x 1; M32 x 1.5; | 1 3/8–8UN; 1 3/8–9UN; | 1 3/8–11; 1 3/8–12; | 1–11 |

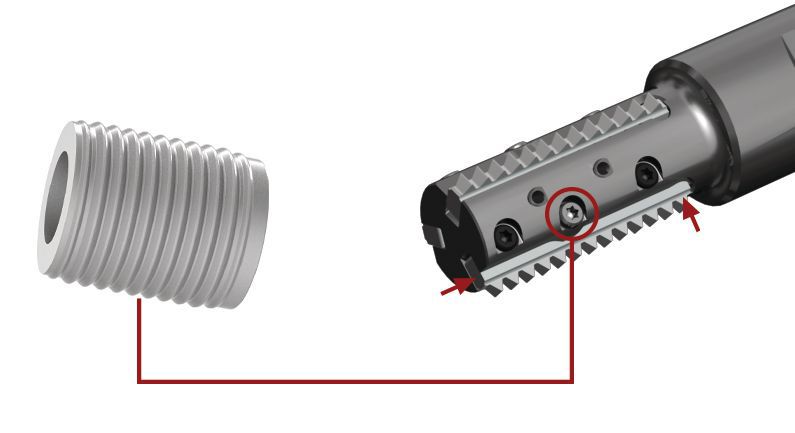

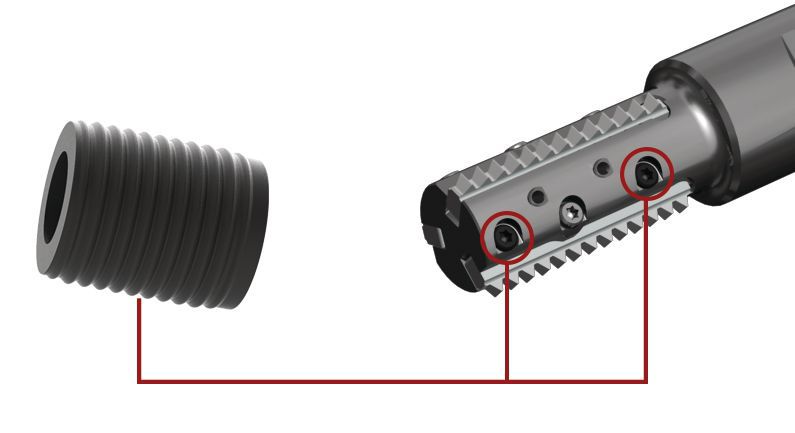

| 2 Step Clamping System |

| Step 1. Location Screw |

|

| Step 2. Clamping Screw (2) |

|

I have read and accepted the Terms & Conditions of use