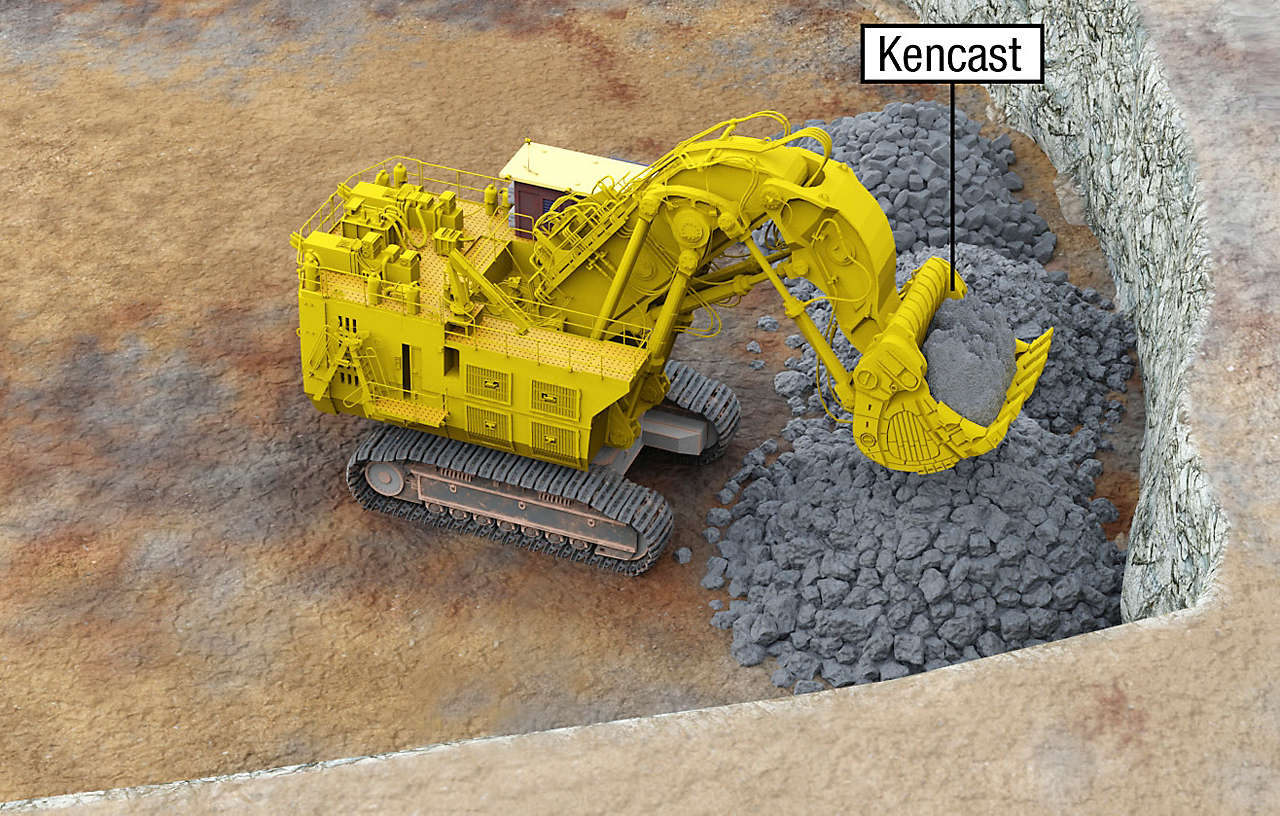

KenCast™ for Surface Mining & Underground Mining

Whether you’re mining above the ground or below, KenCast has the capabilities to ensure your mining equipment withstands all forms of wear and tear. At Kennametal, we understand the tough environments that your mining equipment and components endure daily, so we work to prevent and lessen the impact that abrasion, sliding, and other types of wear have on your jobs.

KenCast has proven its worth for not only mining machines, but their components as well. From longwall and continuous miners to continuous loading arms (CLAs) and surface mining buckets, Kennametal has your mining equipment covered.

Our wear experts developed KenCast for your components as well to ensure your job is protected from wear entirely. Because of its versatility, KenCast has been a proven solution for mining parts such as CLA tips, bucket lips, skid plates, heel bands, and wing shrouds.