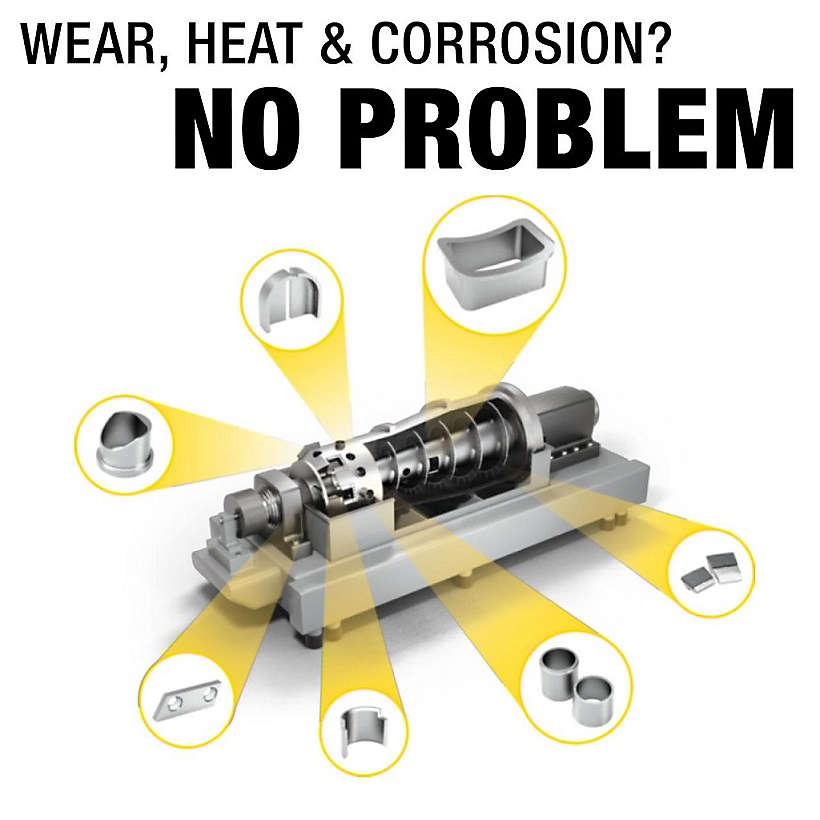

Complete Wear Solutions for Centrifuge Machines

With a thorough understanding of our customers’ process and application challenges, we proactively address wear, heat, and corrosion problems to deliver productivity, reliability, and extended life to Original Equipment Manufacturers (OEM) and rebuilders of centrifugal separation equipment.

We supply standard and custom wear components from tungsten carbide-based material which include sintered carbide blanks and ready-to-use components. Additionally, we perform analytical services to help you develop or improve the service life of your centrifuge equipment through failure analysis, material analysis, wear and corrosion tests, and product engineering.

Decanter Centrifuge Tiles & Components

We have decades of expertise joining steel and carbide using processes like torch, induction, and furnace brazing. And we produce millions of tools and components each year with these processes. We have developed a centrifuge tile that brings OEM quality and reliability to the centrifuge rebuilder as a standard offering to the market.

Corrosion and untimely wear can cause premature tile loss, unbalanced rotation, and excessive vibration of the centrifuge, which all result in unfavorable downtime. Kennametal’s centrifuge tiles are engineered for high reliability and minimize these common problems in solids control and dewatering applications. The carbide tiles are designed to protect the flights from erosion and maintain the separation efficiency of the centrifuge and is the key wear component in the machine.

Kennametal offers a portfolio of solid and screen bowl decanter centrifuge components to complement our line of tiles to ensure your operations run efficiently from start to end. These complementary components include feed and discharge nozzles, scraper bars and plows, wear tile platelets, and screen bars.

The entire separation solutions portfolio enables operators, OEMs, and rebuilders to select from a variety of products and solutions that are designed to provide longevity and reliability across numerous applications and industries.