Count on Kennametal for High-Performance Wear Solutions

Kennametal’s mission is all about solving customer challenges and enabling exceptional performance. Our customer-driven approach has and will continue to set industry standards.

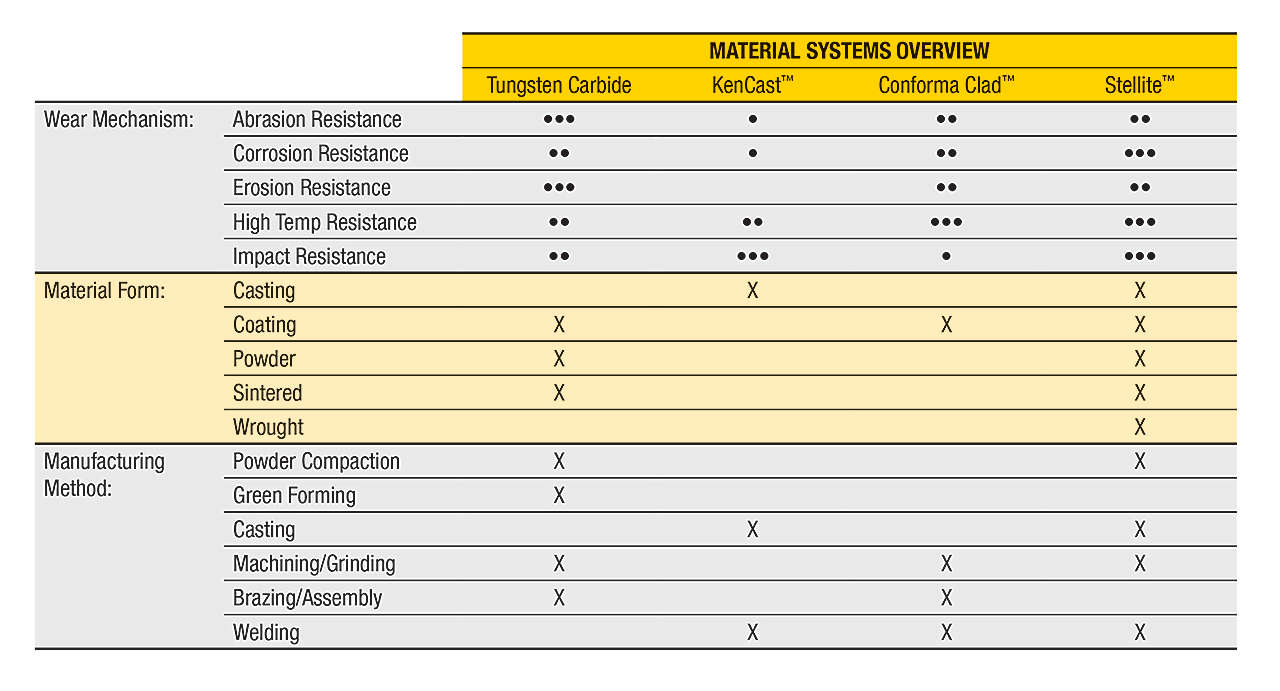

Our portfolio of wear solutions is built on a foundation of deep material science expertise. As a producer and supplier of raw materials, we are able to maintain critical control over our materials. Our primary portfolio of materials includes tungsten carbide, cobalt, nickel, and other specialty additives. We combine these materials to create proprietary formulas and grades to solve specific challenges.