Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

Kennametal steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto Konto ändern

Lieferadresse Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

Notifications

Mark all as read- Passwort ändern

- Mein Profil

- Abmelden

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Mehr bekommen, weniger zahlen mit unseren zeitlich begrenzten angeboten. Jetzt bestellen

Kennametal steht Ihnen zur Diensten

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname:{{SolutionName}}- Produkte

- /

- 7792VXD12 Zylinderschaft • Metrisch

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

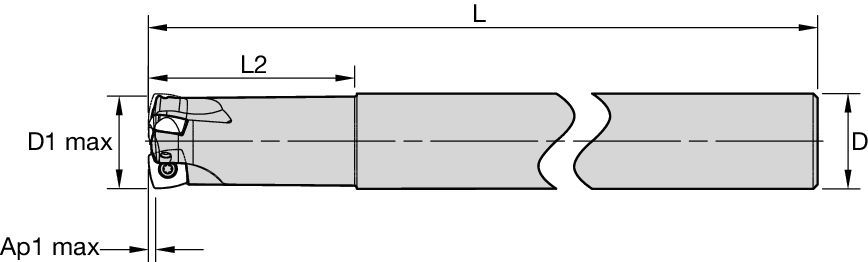

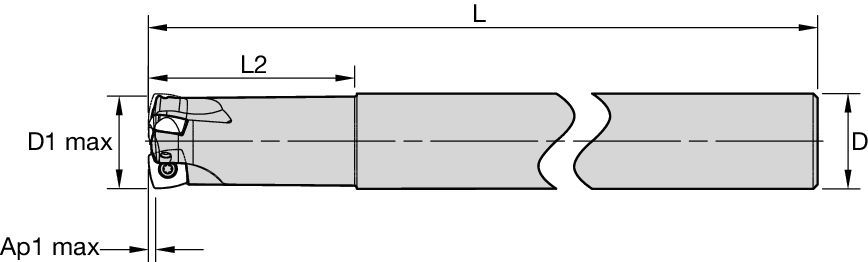

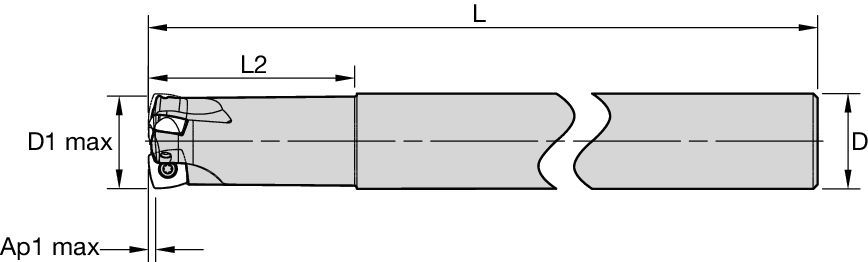

7792VXD12 Zylinderschaft • Metrisch

Fräswerkzeuge für hohe Vorschübe

Features and benefits

- Zur Erhöhung des Zeitspanungsvolumens, speziell bei der Bearbeitung von hochwarmfesten Legierungen, stehen Fräser mit sehr enger Teilung zur Verfügung.

- Die positive Werkzeuggeometrie resultiert in niedrigeren Schnittkräften und erlaubt die Bearbeitung mit langen Werkzeug-Auskragungen.

- Auch zum Eintauchfräsen geeignet.

Uses and application

Spiral Circular

Slotting: Shoulder

Planfräsen

Spiralförmiges Interpolieren

Schräg-Eintauchfräsen Ins Volle

Zylinderschaft – ohne Spannfläche

Fräsen – Innere Kühlmittelzuführung

Auskammern

Senken

Tauchfräsen: Kugelkopf / Vollradius

Inclined Square End Mill

| 7792 Series • IC12 • Insert Selection Guide | ||||||

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | – | (Sert geometri) | |||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1-P2 | ...M41 | KCPM40 | …M41 | KCPM40 | …GP | KCPM40 |

| P3-P4 | ...M41 | KCPM40 | …D411 | SP6519 | …D41 | KCPM40 |

| P5-P6 | ...M41 | KCPM40 | ...D41 | SP6519 | ...D41 | X500 |

| M1-M2 | ...M41 | KCSM40 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| M3 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| K1-K2 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| K3 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S3 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S4 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| H1 | …M | KCKP10 | …M | KCKP10 | …D | KCPM40 |

Bei einer axialen Schnitttiefe von 2,50 (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..D721 | 0,28 | 1,02 | 1,65 | 0,21 | 0,73 | 1,18 | 0,15 | 0,55 | 0,88 | 0,13 | 0,48 | 0,76 | 0,12 | 0,44 | 0,70 | .E..D721 |

| .E..D41 | 0,36 | 1,15 | 1,81 | 0,26 | 0,83 | 1,29 | 0,19 | 0,62 | 0,96 | 0,17 | 0,54 | 0,83 | 0,15 | 0,49 | 0,76 | .E..D41 |

| .E..D411 | 0,36 | 1,15 | 1,81 | 0,26 | 0,83 | 1,29 | 0,19 | 0,62 | 0,96 | 0,17 | 0,54 | 0,83 | 0,15 | 0,49 | 0,76 | .E..D411 |

| .S..GP | 0,51 | 1,30 | 1,99 | 0,37 | 0,93 | 1,41 | 0,28 | 0,70 | 1,05 | 0,24 | 0,61 | 0,91 | 0,22 | 0,55 | 0,83 | .S..GP |

| .S..D | 0,51 | 1,30 | 1,95 | 0,37 | 0,93 | 1,38 | 0,28 | 0,70 | 1,03 | 0,24 | 0,61 | 0,89 | 0,22 | 0,55 | 0,82 | .S..D |

Bei einer axialen Schnitttiefe von 1,70 (ap)

| Light | General | Heavy |

Bei einer axialen Schnitttiefe von 1,30 (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | |||||||||||

| 10% | 20% | 30% | 40–100% | ||||||||||

| ...D721 | 0,32 | 1,86 | 2,10 | 0,24 | 1,37 | 1,54 | 0,21 | 1,19 | 1,34 | 0,19 | 1,09 | 1,22 | ...D721 |

| ...D411 | 0,51 | 2,52 | 3,02 | 0,38 | 1,84 | 2,19 | 0,33 | 1,60 | 1,90 | 0,31 | 1,46 | 1,73 | ...D411 |

| ...D41 | 0,51 | 2,43 | 2,92 | 0,38 | 1,78 | 2,13 | 0,33 | 1,54 | 1,84 | 0,31 | 1,41 | 1,68 | ...D41 |

| ...GP | 0,69 | 2,65 | 3,44 | 0,51 | 1,93 | 2,49 | 0,44 | 1,67 | 2,15 | 0,41 | 1,53 | 1,96 | ...GP |

| ...D | 0,69 | 3,20 | 3,90 | 0,51 | 2,32 | 2,81 | 0,44 | 2,01 | 2,42 | 0,41 | 1,83 | 2,20 | ...D |

Bei einer axialen Schnitttiefe von 1,00 mm (ap)

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..D721 | 0,34 | 1,23 | 2,00 | 0,25 | 0,88 | 1,42 | 0,19 | 0,66 | 1,05 | 0,16 | 0,57 | 0,92 | 0,15 | 0,52 | 0,84 | .E..D721 |

| .E..D41 | 0,43 | 1,39 | 2,20 | 0,31 | 0,99 | 1,56 | 0,23 | 0,74 | 1,15 | 0,20 | 0,64 | 1,00 | 0,19 | 0,59 | 0,92 | .E..D41 |

| .E..D411 | 0,43 | 1,39 | 2,20 | 0,31 | 0,99 | 1,56 | 0,23 | 0,74 | 1,15 | 0,20 | 0,64 | 1,00 | 0,19 | 0,59 | 0,92 | .E..D411 |

| .S..GP | 0,62 | 1,57 | 2,41 | 0,45 | 1,12 | 1,70 | 0,33 | 0,84 | 1,26 | 0,29 | 0,73 | 1,10 | 0,27 | 0,67 | 1,00 | .S..GP |

| .S..D | 0,62 | 1,57 | 2,36 | 0,45 | 1,12 | 1,67 | 0,33 | 0,84 | 1,24 | 0,29 | 0,73 | 1,08 | 0,27 | 0,67 | 0,98 | .S..D |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..D721 | 0,39 | 1,41 | 2,29 | 0,28 | 1,01 | 1,62 | 0,21 | 0,75 | 1,20 | 0,18 | 0,65 | 1,04 | 0,17 | 0,60 | 0,96 | .E..D721 |

| .E..D41 | 0,49 | 1,59 | 2,52 | 0,35 | 1,13 | 1,78 | 0,26 | 0,84 | 1,31 | 0,23 | 0,73 | 1,14 | 0,21 | 0,67 | 1,04 | .E..D41 |

| .E..D411 | 0,49 | 1,59 | 2,52 | 0,35 | 1,13 | 1,78 | 0,26 | 0,84 | 1,31 | 0,23 | 0,73 | 1,14 | 0,21 | 0,67 | 1,04 | .E..D411 |

| .S..GP | 0,70 | 1,80 | 2,76 | 0,51 | 1,28 | 1,94 | 0,38 | 0,95 | 1,44 | 0,33 | 0,83 | 1,25 | 0,30 | 0,76 | 1,14 | .S..GP |

| .S..D | 0,70 | 1,80 | 2,71 | 0,51 | 1,28 | 1,90 | 0,38 | 0,95 | 1,41 | 0,33 | 0,83 | 1,22 | 0,30 | 0,76 | 1,12 | .S..D |

Vorschubempfehlung • Tauchfräsen • IC 12 • fz [mm/Zahn]

| Light | General | Heavy |

| Insert Geometry |  | Programmed Feed per Tooth (fz) | Insert Geometry | ||

| Max 9mm insert engagement (ae radial engagement) | |||||

| .E..D721 | 0,06 | 0,20 | 0,32 | .E..D721 | |

| .E..D41 | 0,07 | 0,23 | 0,35 | .E..D41 | |

| .E..D411 | 0,07 | 0,23 | 0,35 | .E..D411 | |

| .S..GP | 0,10 | 0,25 | 0,38 | .S..GP | |

| .S..D | 0,10 | 0,25 | 0,38 | .S..D | |

Empfohlene Startwerte für Schnittgeschwindigkeiten [m/min]

| Material Group | GH2 | KC510M | KC522M | KC725M | KCK15 | KCPK30 | KCPM20 | KCPM40 | KCSM40 | SC3025 | SC6525 | SP6519 | X400 | X500 | |||||||||||||||||||||||||||||

| P | 1 | – | – | – | – | – | – | 395 | 340 | 325 | 410 | 320 | 280 | – | – | – | 545 | 475 | 445 | 660 | 580 | 540 | 355 | 310 | 295 | – | – | – | – | – | – | 445 | 305 | 170 | 355 | 260 | 155 | 310 | 230 | 145 | 325 | 240 | 155 |

| 2 | – | – | – | – | – | – | 330 | 290 | 240 | 320 | 245 | 210 | – | – | – | 335 | 305 | 275 | 410 | 370 | 330 | 300 | 260 | 215 | – | – | – | – | – | – | 390 | 270 | 145 | 310 | 230 | 140 | 275 | 205 | 125 | 290 | 215 | 140 | |

| 3 | – | – | – | – | – | – | 305 | 260 | 210 | 280 | 210 | 180 | – | – | – | 305 | 275 | 245 | 370 | 330 | 305 | 275 | 235 | 190 | – | – | – | – | – | – | 350 | 240 | 125 | 275 | 200 | 120 | 240 | 180 | 115 | 250 | 185 | 120 | |

| 4 | – | – | – | 295 | 240 | 205 | 270 | 220 | 180 | 235 | 175 | 145 | – | – | – | 230 | 210 | 190 | 275 | 260 | 230 | 245 | 205 | 160 | – | – | – | – | – | – | 250 | 175 | 95 | 210 | 150 | 90 | 180 | 130 | 85 | 190 | 145 | 90 | |

| 5 | – | – | – | – | – | – | 220 | 205 | 180 | 310 | 235 | 190 | – | – | – | 310 | 275 | 250 | 330 | 300 | 275 | 205 | 185 | 160 | 165 | 120 | 85 | – | – | – | 190 | 145 | 95 | 170 | 125 | 85 | – | – | – | 155 | 120 | 85 | |

| 6 | – | – | – | – | – | – | 200 | 150 | 120 | 210 | 155 | 125 | – | – | – | 190 | 160 | 0 | 230 | 205 | 175 | 180 | 140 | 110 | 140 | 100 | 60 | – | – | – | 170 | 120 | 70 | 145 | 100 | 60 | – | – | – | 130 | 95 | 60 | |

| M | 1 | – | – | – | – | – | – | 245 | 215 | 200 | – | – | – | – | – | – | 245 | 220 | 185 | 270 | 240 | 210 | 235 | 205 | 185 | 315 | 225 | 140 | – | – | – | 230 | 185 | 145 | 325 | 235 | 140 | – | – | – | 300 | 220 | 140 |

| 2 | – | – | – | – | – | – | 220 | 190 | 155 | – | – | – | – | – | – | 220 | 190 | 170 | 245 | 210 | 190 | 210 | 180 | 150 | 280 | 205 | 130 | – | – | – | 310 | 220 | 130 | 280 | 205 | 125 | – | – | – | 265 | 190 | 120 | |

| 3 | – | – | – | – | – | – | 170 | 145 | 115 | – | – | – | – | – | – | 175 | 155 | 140 | 190 | 175 | 150 | 155 | 140 | 110 | 230 | 165 | 105 | – | – | – | 250 | 180 | 110 | 235 | 170 | 100 | – | – | – | 215 | 155 | 95 | |

| K | 1 | 300 | 220 | 145 | 355 | 320 | 290 | 275 | 245 | 220 | – | – | – | 505 | 460 | 410 | 355 | 320 | 290 | 430 | 390 | 355 | – | – | – | – | – | – | 475 | 330 | 180 | 470 | 325 | 175 | 355 | 265 | 170 | – | – | – | 335 | 240 | 145 |

| 2 | 260 | 190 | 125 | 275 | 245 | 230 | 215 | 190 | 180 | – | – | – | 400 | 355 | 330 | 280 | 250 | 230 | 340 | 305 | 280 | – | – | – | – | – | – | 400 | 275 | 145 | 365 | 250 | 140 | 290 | 210 | 130 | – | – | – | 245 | 185 | 125 | |

| 3 | 220 | 175 | 120 | 235 | 210 | 190 | 180 | 160 | 145 | – | – | – | 335 | 300 | 275 | 235 | 210 | 190 | 290 | 260 | 240 | – | – | – | – | – | – | 330 | 230 | 125 | – | – | – | 265 | 190 | 120 | – | – | – | 205 | 160 | 115 | |

| N | 1 | 3295 | 1890 | 480 | 770 | 685 | 630 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 3295 | 1890 | 480 | 695 | 640 | 590 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 2560 | 1460 | 355 | 695 | 640 | 590 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 40 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 35 | 75 | 55 | 35 | – | – | – | – | – | – | 65 | 50 | 30 | – | – | – | 60 | 40 | 30 |

| 2 | – | – | – | – | – | – | 50 | 40 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | 50 | 40 | 35 | 70 | 50 | 35 | – | – | – | – | – | – | 60 | 40 | 25 | – | – | – | 55 | 40 | 25 | |

| 3 | – | – | – | – | – | – | 60 | 50 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | 60 | 50 | 35 | 80 | 55 | 35 | – | – | – | – | – | – | 65 | 50 | 30 | – | – | – | 60 | 50 | 30 | |

| 4 | – | – | – | – | – | – | 85 | 60 | 40 | – | – | – | – | – | – | 80 | 60 | 40 | – | – | – | 80 | 60 | 40 | 110 | 80 | 50 | – | – | – | – | – | – | 95 | 70 | 45 | – | – | – | 90 | 65 | 40 | |

| H | 1 | – | – | – | 190 | 155 | 110 | 145 | 110 | 85 | – | – | – | – | – | – | – | – | – | 170 | 140 | 115 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 115 | 85 | 55 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 95 | 70 | 40 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Recommended Starting Speeds [SFM]

| Material Group | GH2 | KC510M | KC522M | KC725M | KCK15 | KCPK30 | KCPM20 | KCPM40 | KCSM40 | SC3025 | SC6525 | SP6519 | X400 | X500 | |||||||||||||||||||||||||||||

| P | 1 | – | – | – | – | – | – | 1295 | 1120 | 1060 | 1025 | 905 | 845 | – | – | – | 1790 | 1555 | 1460 | 2165 | 1910 | 1770 | 1165 | 1025 | 965 | – | – | – | – | – | – | 1460 | 1000 | 550 | 1165 | 845 | 510 | 1025 | 750 | 475 | 1060 | 785 | 510 |

| 2 | – | – | – | – | – | – | 1080 | 940 | 785 | 865 | 750 | 630 | – | – | – | 1105 | 1000 | 905 | 1340 | 1220 | 1080 | 985 | 845 | 710 | – | – | – | – | – | – | 1280 | 890 | 475 | 1025 | 750 | 450 | 905 | 670 | 415 | 940 | 710 | 450 | |

| 3 | – | – | – | – | – | – | 1000 | 845 | 690 | 785 | 670 | 550 | – | – | – | 1000 | 905 | 805 | 1220 | 1080 | 1000 | 905 | 770 | 630 | – | – | – | – | – | – | 1140 | 785 | 415 | 905 | 650 | 395 | 785 | 590 | 370 | 830 | 610 | 395 | |

| 4 | – | – | – | 965 | 785 | 670 | 890 | 725 | 590 | 710 | 590 | 475 | – | – | – | 750 | 690 | 630 | 905 | 845 | 750 | 805 | 670 | 535 | – | – | – | – | – | – | 830 | 570 | 310 | 690 | 490 | 295 | 590 | 430 | 275 | 630 | 475 | 295 | |

| 5 | – | – | – | – | – | – | 725 | 670 | 590 | 590 | 535 | 475 | – | – | – | 1025 | 905 | 830 | 1080 | 985 | 905 | 670 | 610 | 535 | 530 | 390 | 280 | – | – | – | 630 | 475 | 310 | 550 | 415 | 275 | – | – | – | 510 | 395 | 275 | |

| 6 | – | – | – | – | – | – | 650 | 490 | 395 | 510 | 395 | 310 | – | – | – | 630 | 535 | – | 750 | 670 | 570 | 590 | 450 | 355 | 450 | 730 | 200 | – | – | – | 550 | 395 | 235 | 475 | 335 | 200 | – | – | – | 430 | 310 | 200 | |

| M | 1 | – | – | – | – | – | – | 805 | 710 | 650 | 670 | 590 | 535 | – | – | – | 805 | 725 | 610 | 890 | 785 | 690 | 770 | 670 | 610 | 1020 | 730 | 450 | – | – | – | 750 | 610 | 475 | 1060 | 770 | 450 | – | – | – | 985 | 725 | 450 |

| 2 | – | – | – | – | – | – | 725 | 630 | 510 | 610 | 510 | 430 | – | – | – | 725 | 630 | 550 | 805 | 690 | 630 | 690 | 590 | 490 | 910 | 675 | 415 | – | – | – | 1025 | 725 | 430 | 925 | 670 | 415 | – | – | – | 865 | 630 | 395 | |

| 3 | – | – | – | – | – | – | 550 | 475 | 370 | 450 | 395 | 310 | – | – | – | 570 | 510 | 450 | 630 | 570 | 490 | 510 | 450 | 355 | 750 | 530 | 340 | – | – | – | 830 | 590 | 355 | 770 | 550 | 335 | – | – | – | 710 | 510 | 310 | |

| K | 1 | 985 | 725 | 475 | 1165 | 1045 | 940 | 905 | 805 | 725 | – | – | – | 1655 | 1520 | 1340 | – | – | – | 1415 | 1280 | 1165 | – | – | – | – | – | – | 1555 | 1080 | 590 | 1535 | 1060 | 570 | 1165 | 865 | 550 | – | – | – | 1105 | 785 | 475 |

| 2 | 845 | 630 | 415 | 905 | 805 | 750 | 710 | 630 | 590 | – | – | – | 1320 | 1165 | 1080 | – | – | – | 1120 | 1000 | 925 | – | – | – | – | – | – | 1320 | 905 | 475 | 1200 | 830 | 450 | 940 | 690 | 430 | – | – | – | 805 | 610 | 415 | |

| 3 | 725 | 570 | 395 | 770 | 690 | 630 | 590 | 535 | 475 | – | – | – | 1105 | 985 | 905 | – | – | – | 940 | 845 | 785 | – | – | – | – | – | – | 1080 | 750 | 415 | – | – | – | 865 | 630 | 395 | – | – | – | 670 | 535 | 370 | |

| N | 1 | 10805 | 6200 | 1570 | 2520 | 2245 | 2065 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 10805 | 6200 | 1570 | 2280 | 2105 | 1925 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 8405 | 4780 | 1165 | 2280 | 2105 | 1925 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 155 | 140 | 95 | 140 | 120 | 95 | – | – | – | 140 | 120 | 95 | – | – | – | 155 | 140 | 120 | 240 | 175 | 110 | – | – | – | – | – | – | 215 | 155 | 90 | – | – | – | 185 | 140 | 90 |

| 2 | – | – | – | – | – | – | 155 | 140 | 95 | 140 | 120 | 95 | – | – | – | 140 | 120 | 95 | – | – | – | 155 | 140 | 120 | 220 | 160 | 100 | – | – | – | – | – | – | 185 | 140 | 85 | – | – | – | 175 | 140 | 85 | |

| 3 | – | – | – | – | – | – | 200 | 155 | 95 | 180 | 140 | 95 | – | – | – | 180 | 140 | 95 | – | – | – | 200 | 155 | 120 | 255 | 180 | 115 | – | – | – | – | – | – | 215 | 155 | 95 | – | – | – | 200 | 155 | 95 | |

| 4 | – | – | – | – | – | – | 275 | 200 | 140 | 235 | 180 | 120 | – | – | – | 235 | 180 | 120 | – | – | – | 260 | 200 | 140 | 355 | 260 | 165 | – | – | – | – | – | – | 310 | 235 | 145 | – | – | – | 290 | 215 | 140 | |

| H | 1 | – | – | – | 630 | 510 | 355 | 475 | 355 | 275 | – | – | – | – | – | – | – | – | – | 550 | 450 | 370 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 370 | 275 | 180 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 310 | 235 | 140 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |