Ein Pionier in der Werkstoffwissenschaft

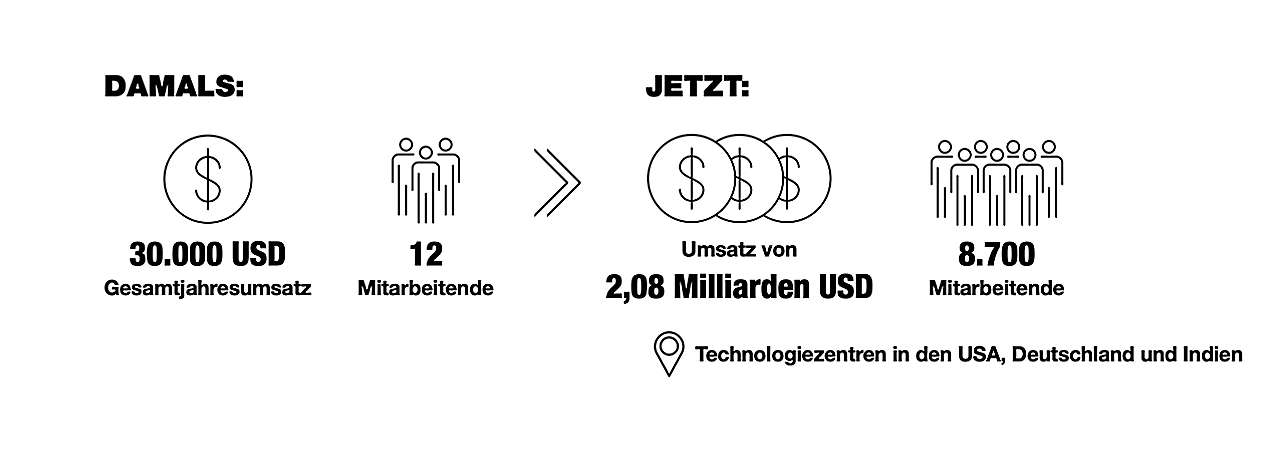

Wir durchbrechen Schranken in der Werkstoffwissenschaft. Diese Mission begann vor 85 Jahren mit unserem Gründer, dem Metallurgen Philip M. McKenna, und hat sich seither stetig fortgesetzt. Nach vielen Jahren der Forschung präsentierte McKenna erstmals eine Wolfram-Titankarbidlegierung, wodurch ein Produktivitätsdurchbruch in der Stahlbearbeitung gelang. Dank der Innovation von McKenna konnten die Schnittgeschwindigkeiten und Standzeiten der Werkzeuge von Kennametal gegenüber denen der Konkurrenz erhöht werden, so dass Kunden aus allen Industriezweigen – vom Transportwesen bis zur Luft- und Raumfahrt – Metall in nie dagewesener Geschwindigkeit bearbeiten konnten.